## Navigating the Global Market: The 304 Stainless Steel Rectangular Tube Exporter

The global demand for high-quality stainless steel products continues to rise, driven by diverse industries ranging from construction and automotive to food processing and medical equipment. Within this robust market, the **304 stainless steel rectangular tube exporter** plays a crucial role, connecting producers with consumers across continents. This article explores the multifaceted nature of this business, highlighting the challenges and opportunities presented in the international trade of this versatile material.

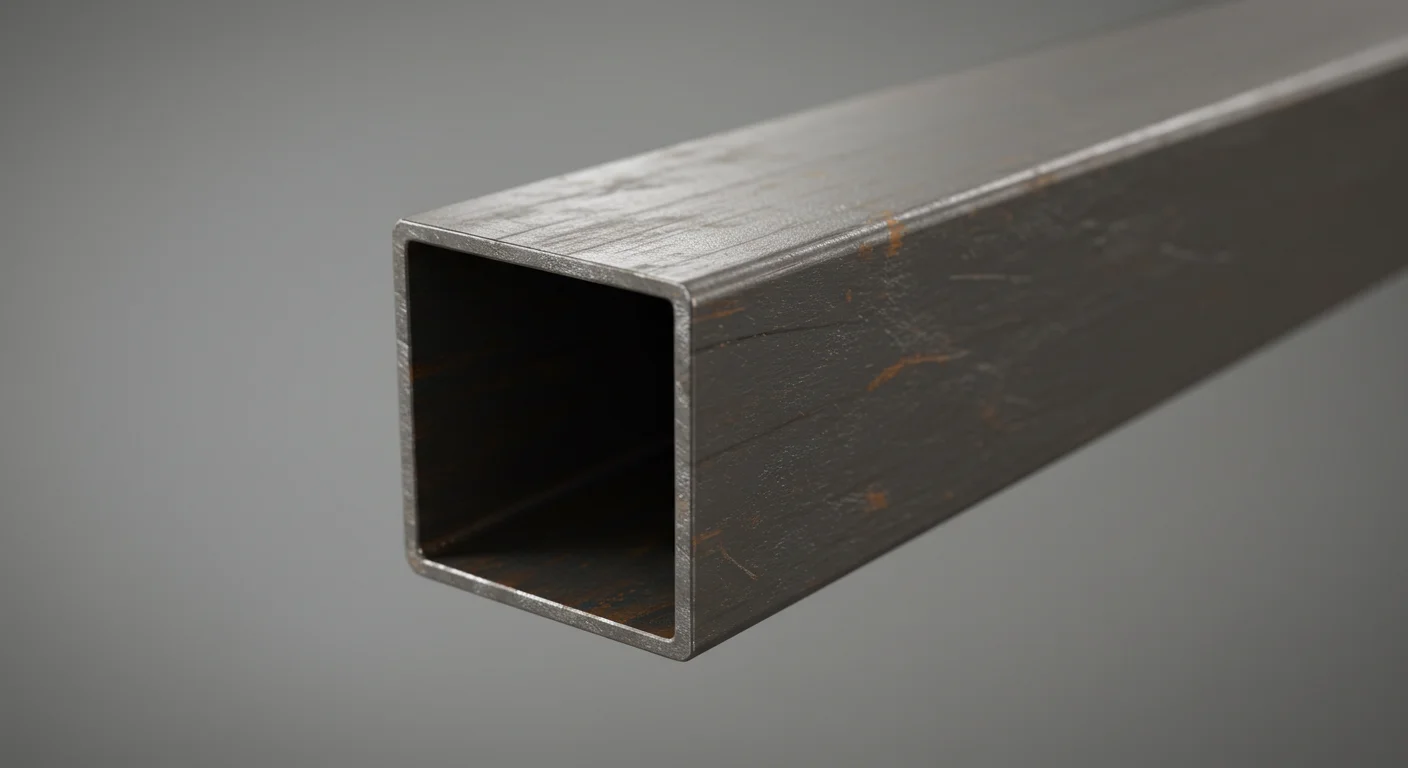

304 stainless steel, renowned for its corrosion resistance, strength, and aesthetic appeal, is a preferred choice for numerous applications requiring durability and hygiene. Its rectangular form offers designers and engineers a distinct advantage, providing structural integrity and a clean, modern aesthetic. This combination of material properties and shape drives significant demand, making the export market highly competitive.

Successful 304 stainless steel rectangular tube exporters must possess a range of capabilities beyond simply sourcing and shipping the product. They need a deep understanding of international trade regulations, including tariffs, import duties, and compliance certifications. Navigating the complex web of international shipping logistics, including customs clearance and documentation, is also paramount. Efficient supply chain management, including sourcing from reliable manufacturers and employing cost-effective transportation methods, is essential for profitability.

Furthermore, exporters must possess strong relationships with international clients and a thorough understanding of market demands. Different regions may have varying specifications and quality standards, requiring exporters to offer tailored solutions and maintain consistent product quality to meet these diverse needs. Building trust with clients through transparency, timely communication, and efficient order fulfillment is critical for long-term success. Effective marketing and branding strategies are also vital in differentiating oneself from competitors and establishing a strong market presence.

The challenges faced by 304 stainless steel rectangular tube exporters are significant. Fluctuations in global steel prices, currency exchange rate volatility, and geopolitical instability can all impact profitability and market stability. Competition is fierce, requiring exporters to continuously innovate and adapt to evolving market trends. Sustainability concerns are also increasingly important, pushing exporters to adopt environmentally responsible practices throughout their supply chains.

Despite these challenges, the opportunities are equally compelling. The ongoing growth of industries relying on 304 stainless steel, coupled with the increasing global demand for high-quality materials, creates a significant market for exporters. Companies that can successfully navigate the complexities of international trade, maintain high standards of quality and customer service, and effectively adapt to changing market conditions are well-positioned for significant growth in this dynamic sector. The 304 stainless steel rectangular tube exporter represents a crucial link in the global supply chain, supporting industries worldwide with a material essential to modern construction and manufacturing.

304 Stainless Steel Rectangular Tube Exporter: Navigating the Global Market — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.

Leave a Reply