Introduction to 304 Stainless Steel Sheet with 2B Finish

What Is 304 Stainless Steel?

304 stainless steel, also known as A2 stainless steel or 18/8 stainless steel, is the most widely used austenitic stainless steel grade. It contains 18% chromium and 8% nickel, offering excellent corrosion resistance, formability, and weldability. This balanced composition makes it ideal for a broad range of applications across industries. Its non-magnetic nature in the annealed state and high ductility further enhance its versatility. For more details, see Stainless steel on Wikipedia.

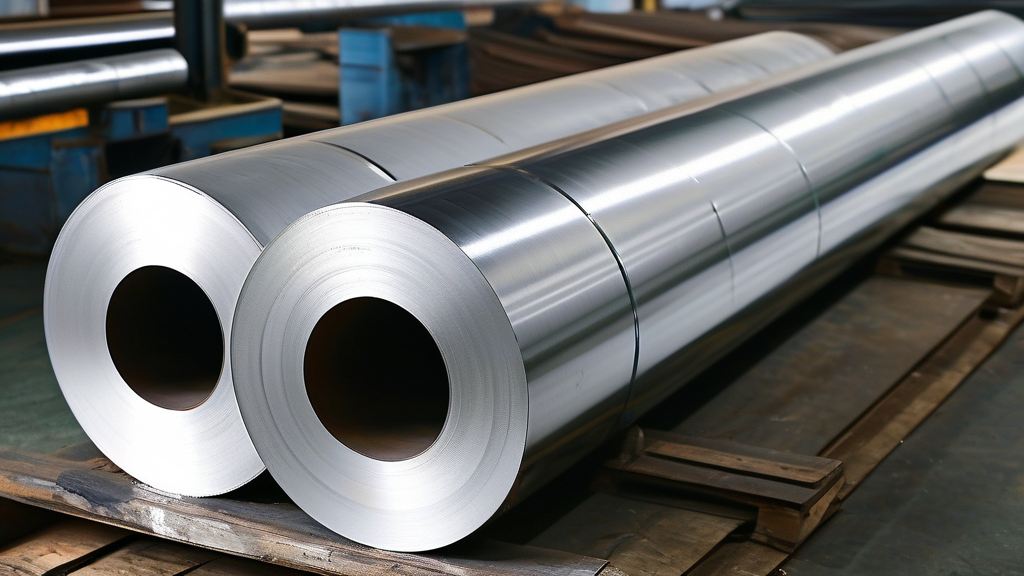

Understanding the 2B Finish

The 2B finish is a smooth, semi-reflective surface achieved through cold rolling, annealing, and pickling. It is the most common finish for 304 stainless steel sheets, balancing aesthetics and functionality. Unlike a No. 4 brushed finish, 2B is less reflective but more cost-effective for industrial applications. The finish is characterized by a uniform, matte-like appearance with minimal surface roughness, making it suitable for both visible and structural components. It is particularly valued for its ease of cleaning and resistance to fingerprinting in commercial environments.

Technical Specifications of 304 Stainless Steel Sheet (2B Finish)

Chemical Composition (ASTM A240/A240M)

The ASTM A240 standard defines the chemical composition of 304 stainless steel, ensuring consistency and reliability in manufacturing:

- Chromium (Cr): 18.0–20.0%

- Nickel (Ni): 8.0–10.5%

- Carbon (C): ≤ 0.08%

- Manganese (Mn): ≤ 2.0%

- Silicon (Si): ≤ 1.0%

- Phosphorus (P): ≤ 0.045%

- Sulfur (S): ≤ 0.03%

This composition ensures optimal performance in corrosive environments and maintains structural integrity under thermal stress. For further reading, refer to Austenitic stainless steel.

Mechanical Properties

304 stainless steel sheets (2B finish) exhibit the following mechanical properties, making them suitable for demanding fabrication processes:

- Tensile Strength: 515–720 MPa

- Yield Strength (0.2% offset): ≥ 205 MPa

- Elongation at Break: ≥ 40%

- Hardness (Brinell): ≤ 201 HB

Physical Properties

- Density: 8.0 g/cm³

- Melting Point: 1400–1450°C

- Thermal Conductivity: 16.2 W/m·K

- Electrical Resistivity: 720 nΩ·m

Dimensional Tolerances for 304 Stainless Steel Sheet (2B Finish)

Thickness Tolerances (ASTM A480/A480M)

The ASTM A480 standard specifies thickness tolerances for 304 stainless steel sheets to ensure precision in manufacturing and assembly:

- 0.3–0.5 mm: ±0.05 mm

- 0.5–1.0 mm: ±0.07 mm

- 1.0–2.0 mm: ±0.10 mm

- 2.0–3.0 mm: ±0.15 mm

Width and Length Tolerances

- Width: ±1.5 mm (for standard widths up to 1500 mm)

- Length: ±2.0 mm (for standard lengths up to 6000 mm)

Flatness and Edge Conditions

- Flatness: ≤ 3 mm/m (for sheets ≤ 1.5 mm thickness)

- Edge Options: Mill edge (uncut) or slit edge (precision-cut)

Key Applications of 304 Stainless Steel Sheet (2B Finish)

Industrial and Manufacturing Uses

- Chemical Processing Equipment: Tanks, pipes, and valves due to corrosion resistance.

- Food & Beverage Industry: Food-grade surfaces, kitchen equipment, and storage tanks compliant with FDA and EU standards.

- Pharmaceutical & Medical Devices: Sterilizable surfaces for surgical tools and lab equipment requiring high hygiene.

Architectural and Decorative Applications

- Interior Cladding & Wall Panels: Smooth, easy-to-clean surfaces for modern buildings and hospitals.

- Elevator & Escalator Panels: Durable and aesthetically pleasing finish resistant to wear and fingerprints.

- Signage & Nameplates: Laser-cut or etched designs with a polished look for branding and identification.

Automotive and Transportation

- Exhaust Systems: Heat and corrosion resistance in high-temperature environments.

- Trim & Molding: Lightweight yet durable for vehicle exteriors and interior accents.

Household and Consumer Goods

- Appliances: Refrigerators, dishwashers, and ovens with long-lasting, hygienic surfaces.

- Furniture & Fixtures: Modern stainless steel tables, shelves, and lighting fixtures with a sleek 2B finish.

Advantages and Limitations of 304 Stainless Steel (2B Finish)

Advantages

- ✔ Corrosion Resistance: Performs well in acidic and chloride environments, though not as robust as 316 in marine settings.

- ✔ Formability & Weldability: Easy to fabricate without cracking, ideal for complex shapes and joints.

- ✔ Hygienic Properties: Non-porous, ideal for food and medical applications requiring frequent cleaning.

- ✔ Cost-Effective: More affordable than 316 stainless steel for general use, offering excellent value.

Limitations

- ✖ Lower Hardness: Not ideal for high-wear applications; consider 430 or 440C for abrasive environments.

- ✖ Magnetic Response: Can become slightly magnetic after cold working due to strain-induced martensite formation.

- ✖ Chloride Stress Corrosion: Avoid prolonged exposure to saltwater; use 316L instead for marine or coastal applications.

Maintenance and Care for 2B Finish Stainless Steel Sheets

Cleaning Best Practices

- Use mild detergent and warm water for routine cleaning.

- Avoid chloride-based cleaners (e.g., bleach) to prevent pitting and corrosion.

- For stubborn stains, use isopropyl alcohol or vinegar solutions with a soft cloth.

Preventing Scratches and Damage

- Store sheets face-to-face with protective film to prevent surface abrasion.

- Use soft cloths or non-abrasive pads during handling and installation.

Conclusion: Why Choose 304 Stainless Steel Sheet (2B Finish)?

304 stainless steel with a 2B finish is a versatile, cost-effective solution for industries requiring durability, corrosion resistance, and a smooth surface. Whether for industrial fabrication, architecture, or consumer goods, this material delivers consistent performance and long-term value. Its compliance with international standards, ease of fabrication, and aesthetic appeal make it a preferred choice across sectors. For specialized applications involving high chloride exposure, consider 316 stainless steel for enhanced chloride resistance. For further technical details, consult Stainless steel grades on Wikipedia.