Introduction to 316L Stainless Steel Plate: A Benchmark in Corrosion Resistance

What Is 316L Stainless Steel?

316L stainless steel is an austenitic chromium-nickel alloy with added molybdenum, specifically engineered to enhance resistance to pitting and crevice corrosion in chloride-rich environments. The “L” designation indicates a low carbon content (≤0.03%), which minimizes carbide precipitation during welding—critical for maintaining corrosion resistance in welded structures. This grade is widely used in marine, chemical processing, pharmaceutical, and food industries. For a foundational understanding of stainless steel classifications, refer to the Stainless steel Wikipedia page.

Key Alloying Elements and Their Roles

The performance of 316L hinges on its precise chemical composition:

- Chromium (16–18%): Forms a passive oxide layer that protects against oxidation and general corrosion.

- Nickel (10–14%): Stabilizes the austenitic structure, improving ductility and resistance to stress corrosion cracking.

- Molybdenum (2–3%): The defining differentiator from 304/304L; significantly enhances resistance to pitting and crevice corrosion, especially in halide-containing environments.

- Low Carbon (≤0.03%): Prevents sensitization (chromium carbide formation at grain boundaries) during thermal exposure, preserving intergranular corrosion resistance.

Corrosion Performance of 316L Stainless Steel Plate

Resistance to Pitting and Crevice Corrosion

316L excels in environments with chlorides, such as seawater, de-icing salts, and brines. The molybdenum content increases the pitting resistance equivalent number (PREN), calculated as:

PREN = %Cr + 3.3 × %Mo + 16 × %N

316L typically has a PREN of 25–30, compared to ~19 for 304L, making it suitable for marine and offshore applications. For more on pitting corrosion mechanisms, see Pitting corrosion.

Intergranular Corrosion and Sensitization

The low carbon content in 316L mitigates sensitization—a phenomenon where chromium carbides form at grain boundaries during welding or heat treatment, depleting chromium and creating localized corrosion sites. This makes 316L ideal for welded components without requiring post-weld annealing. However, prolonged exposure to temperatures between 425°C and 815°C (the “sensitization range”) can still pose risks.

Stress Corrosion Cracking (SCC) Resistance

While 316L performs better than 304L in chloride-induced SCC, it is not immune. In high-temperature chloride environments (e.g., >60°C), SCC can still occur. For critical applications, duplex stainless steels (e.g., 2205) or higher-molybdenum alloys (e.g., 317L, 904L) may be preferred. Refer to Stress corrosion cracking for a detailed breakdown.

Performance in Acidic and Alkaline Environments

316L shows good resistance to organic acids (e.g., acetic, citric) and weak inorganic acids (e.g., phosphoric). However, it is not recommended for strong reducing acids (e.g., hydrochloric acid) or concentrated sulfuric acid. In alkaline environments (e.g., sodium hydroxide), 316L performs well up to moderate concentrations and temperatures.

Comparative Analysis: 316L vs. Other Stainless Steel Grades

316L vs. 304/304L: When to Upgrade?

While 304L is cost-effective for general-purpose applications, 316L is the clear choice in chloride-exposed or mildly acidic environments. The added molybdenum in 316L increases cost by ~15–25%, but the extended service life and reduced maintenance often justify the investment.

316L vs. 317L and 904L: High-Performance Alternatives

317L (3–4% Mo) and 904L (4–5% Mo, with copper) offer superior pitting resistance and are used in highly aggressive environments (e.g., flue gas desulfurization, chemical reactors). However, 316L remains the optimal balance of performance, availability, and cost for most industrial applications.

316L vs. Duplex Stainless Steels (e.g., 2205)

Duplex grades offer higher strength and better SCC resistance but are more sensitive to heat input during welding. 316L is easier to fabricate and remains the preferred choice for thin-plate applications and complex geometries.

Selection Guide for 316L Stainless Steel Plate

Environmental Considerations

Evaluate the operating environment:

- Marine/offshore: 316L is standard for splash zones and submerged components.

- Chemical processing: Use 316L for mild acids, alkalis, and organic media; upgrade for strong chlorides or high temperatures.

- Pharmaceutical and food processing: 316L meets sanitary standards (e.g., ASTM A270, 3-A) and resists cleaning agents (e.g., CIP solutions).

Mechanical and Fabrication Requirements

316L offers excellent formability, weldability (TIG, MIG, resistance), and machinability (though it work-hardens rapidly). For welded structures, 316L is preferred over 316 due to its resistance to intergranular attack. Post-weld heat treatment (PWHT) is generally not required.

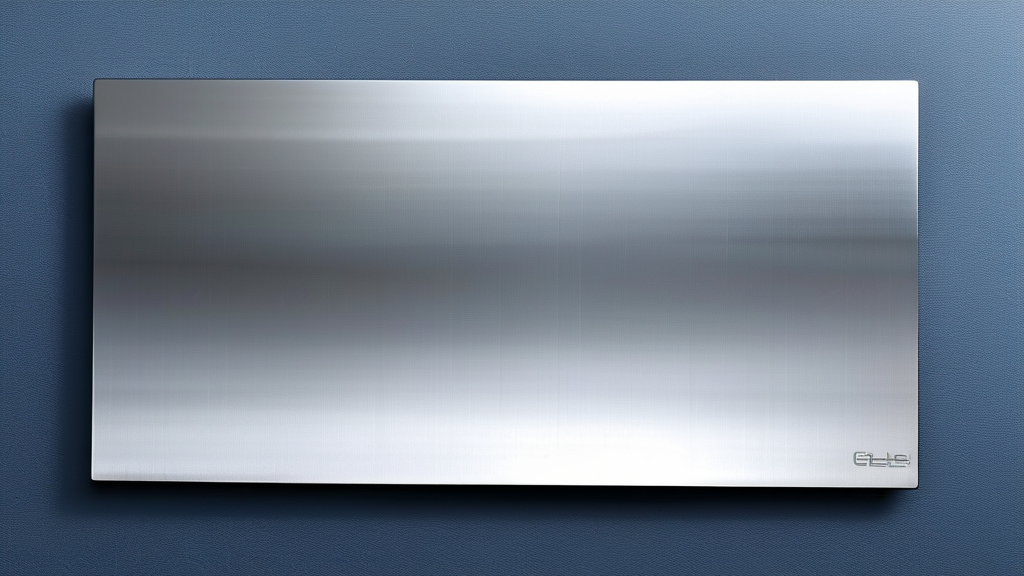

Surface Finish and Aesthetic Needs

Available finishes include:

- 2B (cold-rolled, annealed, pickled): Standard for industrial use.

- BA (bright annealed): High reflectivity, used in architectural and medical applications.

- No. 4 (polished): Sanitary finish for food and pharmaceutical equipment.

Surface finish impacts corrosion resistance—smoother finishes reduce crevice formation and microbial adhesion.

Standards and Certifications

Ensure compliance with:

- ASTM A240/A240M: Standard specification for chromium and chromium-nickel stainless steel plate, sheet, and strip.

- EN 10088-2: European standard for stainless steels.

- ASME BPVC Section II: For pressure vessel applications.

Always request mill test certificates (MTCs) verifying chemical composition and mechanical properties.

Maintenance and Long-Term Performance Optimization

Cleaning and Passivation

Regular cleaning with non-chlorinated detergents and periodic passivation (using citric or nitric acid) restore the protective oxide layer. Avoid abrasive cleaners that damage the passive film.

Monitoring and Inspection

In critical applications, implement non-destructive testing (NDT) methods such as ultrasonic testing (UT) or dye penetrant inspection (PT) to detect early-stage pitting or cracking.

Lifecycle Cost Analysis

While 316L has a higher initial cost than 304L, its extended service life, reduced downtime, and lower maintenance needs result in lower total cost of ownership (TCO) in corrosive environments.

Conclusion: Making the Right Choice with 316L Stainless Steel Plate

316L stainless steel plate remains the industry benchmark for applications requiring reliable corrosion resistance, weldability, and mechanical performance. By understanding its corrosion mechanisms, comparing it with alternative grades, and applying a systematic selection process, engineers and procurement specialists can ensure optimal performance and longevity. For further reading on metallurgical principles, consult the Austenitic stainless steel Wikipedia entry.

Related Products and Next Steps

Use these links to compare options and send RFQ with complete specs.