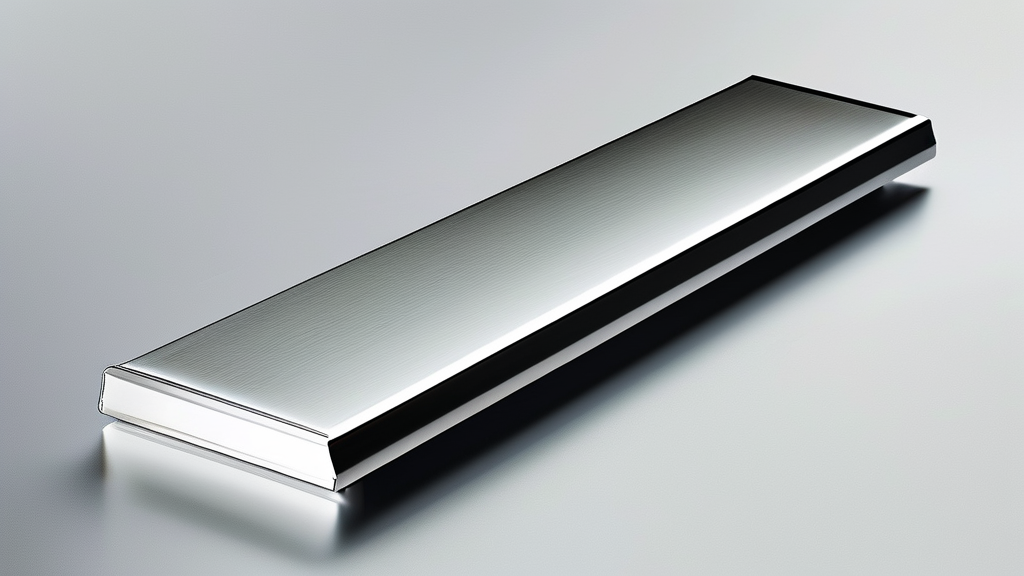

Introduction to 430 Stainless Steel Sheet: A Balanced Alloy for Industrial Applications

Overview of 430 Stainless Steel Composition and Classification

430 stainless steel is a ferritic, non-hardenable grade containing approximately 16–18% chromium and low carbon content (typically ≤0.12%). As a member of the 400 series, it lacks nickel, which significantly impacts its cost, magnetic behavior, and corrosion resistance. This composition places 430 in the ferritic stainless steel category, known for its body-centered cubic (BCC) crystal structure and inherent magnetism. Its balance of affordability and moderate performance makes it a preferred choice in consumer appliances, automotive trim, and architectural components.

Key Applications Driving Demand for 430 Stainless Steel Sheets

Due to its formability, surface finish, and cost-efficiency, 430 stainless steel sheets are widely used in kitchen appliances (e.g., oven liners, dishwasher panels), automotive exhaust systems, roofing, and decorative trims. Its suitability for deep drawing and stamping processes further enhances its industrial appeal, especially where high strength or extreme corrosion resistance is not the primary requirement.

Magnetic Behavior of 430 Stainless Steel: The Ferritic Advantage

Why 430 Stainless Steel Is Magnetic

Unlike austenitic grades (e.g., 304 or 316), 430 stainless steel exhibits strong ferromagnetism due to its ferritic microstructure. The absence of nickel prevents the formation of the face-centered cubic (FCC) austenite phase, preserving the magnetic BCC structure. This property is critical in applications requiring magnetic response, such as electromagnetic shielding, sensor housings, and certain automotive components.

Implications of Magnetism in Industrial and Consumer Use

The magnetic nature of 430 sheets enables easy detection via magnetic sensors and simplifies handling in automated manufacturing lines. However, it may limit use in applications where non-magnetic materials are required (e.g., MRI environments or precision electronics). Engineers must evaluate magnetic interference risks when integrating 430 into sensitive systems. For a deeper understanding of magnetic properties in metals, refer to the magnetism in materials page.

Comparison with Non-Magnetic Austenitic Grades (304/316)

While 304 and 316 stainless steels are typically non-magnetic in the annealed state, cold working can induce partial magnetism. In contrast, 430 remains consistently magnetic regardless of processing. This predictability makes 430 a reliable choice for applications where magnetic consistency is essential.

Corrosion Resistance: Performance in Challenging Environments

Mechanism of Corrosion Resistance in 430 Stainless Steel

The chromium content in 430 (16–18%) forms a passive oxide layer that protects against oxidation and mild corrosive agents. However, without nickel or molybdenum, this layer is less robust than in austenitic grades. The passivation process is critical to maximizing surface protection, especially in humid or mildly acidic environments.

Limitations in Corrosive Environments

430 performs well in indoor, dry, or mildly corrosive conditions (e.g., kitchen appliances, indoor architectural panels). However, it is prone to pitting and crevice corrosion in chloride-rich environments (e.g., coastal areas, de-icing salts). It also lacks resistance to sulfuric and hydrochloric acids, limiting its use in chemical processing. For applications requiring high corrosion resistance, 316 stainless steel remains superior.

Real-World Performance: Case Studies and Field Data

Field studies show that 430 sheets used in automotive exhaust systems exhibit surface rust after 3–5 years in high-salinity regions, whereas 409 or 439 grades (with added titanium or niobium) perform better. In contrast, 430 maintains integrity in indoor HVAC components for over a decade, demonstrating its suitability in controlled environments.

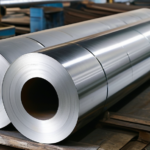

Cost Efficiency: The Economic Edge of 430 Stainless Steel

Raw Material Cost Breakdown: Nickel-Free Advantage

The absence of nickel—a volatile and expensive alloying element—makes 430 significantly cheaper than 304 or 316. As of 2024, 430 stainless steel sheets cost approximately 30–40% less than 304 equivalents. This cost differential is a major driver in high-volume manufacturing, where material savings directly impact profitability.

Processing and Fabrication Cost Considerations

430 sheets are easier to cut, form, and weld than many austenitic grades due to lower work-hardening rates. However, they are more prone to sensitization (chromium carbide precipitation) during welding, which can reduce corrosion resistance. Proper welding techniques (e.g., low heat input, post-weld annealing) are essential to maintain performance. Despite these nuances, overall fabrication costs remain lower than for nickel-containing alloys.

Total Cost of Ownership (TCO) Analysis

While 430 has lower upfront and processing costs, its shorter service life in corrosive environments may increase long-term maintenance or replacement expenses. A TCO analysis must weigh initial savings against lifecycle performance. For example, in coastal construction, switching to 316 may reduce maintenance costs by 50% over 15 years, despite higher initial investment.

Balancing Magnetic Behavior, Corrosion, and Cost: Strategic Selection Criteria

Decision Matrix: When to Choose 430 Over Other Grades

Use 430 when:

- Magnetic properties are required or acceptable

- Exposure to chlorides or acids is minimal

- Budget constraints are critical

- Aesthetic finish (e.g., bright, polished surfaces) is a priority

Avoid 430 in marine, chemical, or high-temperature (>800°C) applications.

Hybrid Solutions and Alloy Substitutions

In borderline cases, consider 439 (stabilized with titanium) or 444 (with molybdenum) for improved corrosion resistance without sacrificing magnetism. Alternatively, use 430 for non-critical components and 304 for exposed areas—a cost-optimized hybrid approach.

Future Trends: Recycling and Sustainability Impact

430’s high recyclability (over 90% recovery rate in industrial scrap streams) enhances its sustainability profile. As circular economy principles gain traction, the low environmental footprint of 430—combined with its cost efficiency—positions it as a strategic material in green manufacturing. For more on stainless steel recycling, see stainless steel recycling.

Conclusion: Optimizing Material Selection with 430 Stainless Steel

Summary of Key Trade-Offs

430 stainless steel offers a compelling balance: strong magnetism, moderate corrosion resistance, and exceptional cost efficiency. It is not a universal solution, but a highly effective one in the right context.

Final Recommendations for Engineers and Procurement Teams

Conduct a thorough environmental and functional assessment before selecting 430. Leverage its strengths in non-corrosive, magnetically compatible applications while planning for protective coatings or alloy upgrades in harsher conditions. With proper specification, 430 remains a cornerstone of cost-effective, high-performance stainless steel solutions.