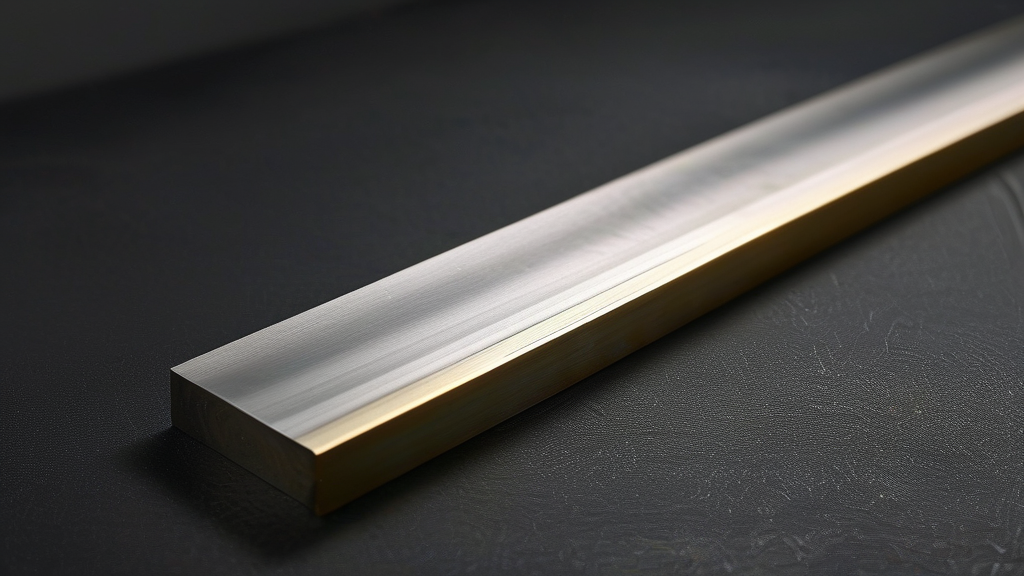

Introduction to 440C Stainless Steel Bar: A High-Performance Alloy for Demanding Applications

Overview of 440C Stainless Steel Composition

440C stainless steel is a high-carbon martensitic stainless steel known for its exceptional hardness, wear resistance, and moderate corrosion resistance. Composed primarily of iron, chromium (16–18%), carbon (0.95–1.20%), and smaller amounts of manganese, silicon, molybdenum (0.75% max), and phosphorus/sulfur, this alloy is engineered for applications requiring high strength and durability. The elevated carbon content enables deep hardening through heat treatment, making it ideal for precision components such as bearings, valves, and cutting tools. For a detailed breakdown of its chemical composition, refer to the 440C stainless steel entry on Wikipedia.

Key Applications and Industry Use Cases

Due to its balanced mechanical properties, 440C stainless steel bars are widely used in aerospace, medical instruments, firearms, and industrial cutting tools. Its ability to maintain sharpness and resist deformation under stress makes it a preferred material in high-wear environments. The alloy’s moderate corrosion resistance—superior to 440A and 440B—allows it to perform in mildly corrosive conditions, though not in highly acidic or chloride-rich environments.

Hardness Characteristics of 440C Stainless Steel Bar

Achievable Hardness Range and Rockwell C Scale (HRC)

One of the defining features of 440C stainless steel is its high hardness potential. When properly heat-treated, 440C can achieve a hardness of 58–60 HRC, with some specialized treatments pushing it to 62 HRC. This places it among the hardest stainless steels commercially available. The high carbon content enables the formation of fine, hard chromium carbides during quenching, which significantly enhance surface hardness and wear resistance.

Factors Influencing Hardness: Grain Size, Carbide Distribution, and Cooling Rate

The final hardness of 440C is highly dependent on microstructural control. Rapid quenching from the austenitizing temperature (typically 1010–1065°C) suppresses the formation of softer phases like ferrite or pearlite, promoting a fully martensitic structure. Fine grain size and uniform dispersion of chromium carbides (primarily M₇C₃ type) are critical for maximizing hardness and minimizing brittleness. Improper cooling rates or inadequate tempering can lead to retained austenite or excessive residual stress, reducing effective hardness.

Comparison with Other 440 Series Grades (440A, 440B)

440C contains the highest carbon content in the 440 series, directly correlating with its superior hardness. 440A (0.65–0.75% C) typically reaches 56–58 HRC, while 440B (0.75–0.95% C) achieves 57–59 HRC. The incremental increase in carbon in 440C results in a denser carbide network, enhancing wear performance at the cost of slightly reduced toughness and corrosion resistance.

Heat Treatment Process for 440C Stainless Steel Bar

Austenitizing: Temperature and Soak Time Optimization

The first critical step in heat treatment is austenitizing, where the steel is heated to 1010–1065°C (1850–1950°F) to dissolve carbides and form a homogeneous austenite phase. Soak time should be approximately 1 hour per inch of thickness to ensure uniform temperature distribution. Overheating (>1065°C) can lead to grain coarsening, reducing toughness and increasing the risk of quench cracking.

Quenching: Medium Selection and Cooling Rate Control

Rapid quenching is essential to transform austenite into martensite. Common quenching media include oil (most common), air, or high-pressure gas. Oil quenching provides a controlled cooling rate that minimizes distortion and cracking while achieving full hardness. For large or complex sections, vacuum heat treatment with high-pressure gas quenching (HPGQ) is preferred to reduce thermal gradients and residual stress.

Tempering: Balancing Hardness and Toughness

After quenching, 440C is typically tempered between 150–370°C (300–700°F) to relieve internal stresses and improve toughness. Tempering at lower temperatures (150–200°C) preserves maximum hardness (58–60 HRC) but results in lower impact resistance. For applications requiring better ductility, tempering at 300–370°C reduces hardness to 55–58 HRC but significantly improves fracture toughness. Multiple tempering cycles (e.g., double tempering) are recommended to stabilize the microstructure and eliminate retained austenite.

Sub-Zero (Cryogenic) Treatment: Enhancing Dimensional Stability

For critical applications requiring maximum hardness and minimal dimensional change, cryogenic treatment (down to -70°C to -196°C) can be applied after quenching and before tempering. This process converts retained austenite to martensite, improving wear resistance and long-term stability. Studies show cryogenic treatment can increase hardness by 1–2 HRC and extend tool life by up to 30%.

Wear Performance and Tribological Behavior of 440C Stainless Steel

Mechanisms of Wear Resistance: Carbide Formation and Surface Hardness

The wear performance of 440C is primarily governed by its high surface hardness and the presence of hard chromium carbides (Cr₇C₃) embedded in the martensitic matrix. These carbides act as load-bearing particles, resisting abrasive and adhesive wear. The fine dispersion of carbides—achieved through proper heat treatment—ensures uniform wear resistance across the surface, reducing the risk of localized pitting or galling.

Performance in Abrasive and Adhesive Wear Environments

In abrasive wear scenarios (e.g., sand or particle-laden environments), 440C outperforms lower-carbon stainless steels due to its higher hardness. In adhesive wear (e.g., metal-to-metal contact under load), the alloy’s ability to form a stable oxide layer (Cr₂O₃) provides some self-lubricating properties, reducing friction and galling. However, in high-load sliding applications, surface treatments such as nitriding or PVD coatings are often applied to further enhance wear life.

Comparison with Competing Materials (D2 Tool Steel, 17-4 PH, 316L)

- D2 Tool Steel: Offers similar hardness (60–62 HRC) but lower corrosion resistance. 440C is preferred in corrosive environments where wear resistance is still critical.

- 17-4 PH Stainless Steel: Higher toughness and better corrosion resistance, but lower hardness (max ~44 HRC after aging). Suitable for structural components, not high-wear applications.

- 316L Stainless Steel: Excellent corrosion resistance but very low hardness (~20 HRC), making it unsuitable for wear-prone applications.

440C strikes a unique balance between hardness, wear resistance, and moderate corrosion resistance, making it ideal for hybrid environments.

Surface Treatments to Enhance Wear Performance

To further improve wear resistance, 440C bars are often subjected to surface engineering techniques:

- Nitriding: Forms a hard nitride layer (up to 70 HRC) with improved fatigue resistance.

- Physical Vapor Deposition (PVD): Applies thin, hard coatings (e.g., TiN, CrN) to reduce friction and increase surface hardness.

- Laser Cladding: Deposits wear-resistant alloys (e.g., Stellite) for extreme wear conditions.

Practical Considerations for Machining and Fabrication

Machinability Challenges and Best Practices

440C is classified as a “difficult-to-machine” alloy due to its high hardness and work-hardening tendency. In the annealed state (220–260 HB), it can be machined with carbide or ceramic tooling using low speeds, high feed rates, and ample coolant. Pre-heat treatment to a softer state (e.g., stress-relieved) is recommended for complex geometries.

Welding Limitations and Post-Weld Heat Treatment

Welding 440C is not recommended due to its high carbon content, which promotes carbide precipitation and embrittlement in the heat-affected zone (HAZ). If welding is unavoidable, pre-heating to 200–300°C and post-weld annealing at 760°C followed by slow cooling are essential to prevent cracking.

Corrosion Resistance: Real-World Performance and Limitations

While 440C offers better corrosion resistance than carbon steels, it is not suitable for marine or highly acidic environments. The high carbon content reduces chromium availability for passive film formation. For enhanced corrosion resistance, consider electropolishing or passivation treatments. For more on stainless steel corrosion mechanisms, see Stainless steel.

Conclusion: Optimizing 440C Stainless Steel for Performance and Longevity

Summary of Key Performance Attributes

440C stainless steel bar excels in applications demanding high hardness, wear resistance, and dimensional stability. Its performance is maximized through precise heat treatment, including austenitizing, quenching, tempering, and optional cryogenic treatment.

Selection Guidelines for Engineers and Designers

Choose 440C when wear resistance is paramount and operating conditions are mildly corrosive. Pair with appropriate surface treatments for extreme environments. Avoid in high-impact or highly corrosive applications where 17-4 PH or duplex stainless steels may be more suitable.

Future Trends and Material Innovations

Ongoing research focuses on nano-carbide dispersion, additive manufacturing of 440C, and hybrid coatings to further enhance performance. As industries demand longer-lasting, high-precision components, 440C remains a cornerstone material in advanced metallurgy.