The food industry operates under some of the most stringent regulations concerning hygiene, safety, and material durability. From processing plants to commercial kitchens, every component must withstand rigorous cleaning, corrosive substances, and constant use. In this demanding environment, the choice of materials is paramount. Among the various options, 316 stainless steel angle bars stand out as an exceptionally suitable and often preferred material. Their unique properties make them indispensable for ensuring both operational efficiency and compliance with health standards, making them a cornerstone for modern food processing infrastructure.

The Superior Properties of 316 Stainless Steel for Food Applications

What exactly makes 316 stainless steel so ideal for the food sector? It primarily comes down to its refined chemical composition. While 304 stainless steel is commonly used for general purposes, the 316 grade distinguishes itself with a significant addition of molybdenum, typically ranging between 2-3%. This seemingly small alloying element dramatically enhances its resistance to corrosion, particularly against chlorides, acids, and other industrial solvents that are prevalent in food processing environments. This enhanced resistance directly translates into increased longevity and safety for critical equipment.

- Exceptional Corrosion Resistance: This is the cornerstone of 316 SS’s suitability. Food products often contain naturally occurring acids (like citric acid in fruits or lactic acid in dairy), high salt concentrations, and various harsh cleaning agents such as chlorine-based sanitizers. 316 stainless steel exhibits superior resistance to pitting and crevice corrosion, ensuring long-term integrity even when consistently exposed to these aggressive substances. This is absolutely crucial for maintaining the structural integrity of equipment, preventing material degradation, and, most importantly, eliminating potential sources of contamination.

- Superior Hygiene and Cleanability: The smooth, non-porous surface of 316 stainless steel makes it incredibly easy to clean and sanitize effectively. Unlike other materials with rougher textures or microscopic imperfections, bacteria, fungi, and other undesirable microorganisms have nowhere to cling or proliferate. This characteristic is vital for preventing biofilm formation and cross-contamination, playing a critical role in meeting stringent regulatory requirements such as HACCP (Hazard Analysis and Critical Control Points) and FDA guidelines.

- High Temperature Resistance: Many food processing operations involve extreme temperature variations, from high-temperature cooking and pasteurization processes to intense steam cleaning and sterilization cycles. 316 SS maintains its strength, structural stability, and integrity even under these elevated temperatures, without deforming, softening, or leaching harmful substances into the food products. This thermal stability is a key advantage.

- Durability and Strength: Food industry equipment faces significant mechanical stress from continuous operation, heavy loads, vibrations, and frequent rigorous cleaning cycles. Stainless steel angle bars made from 316 grade offer excellent tensile strength, yield strength, and toughness. This ensures that components can withstand these daily rigors and provide a long, reliable service life, significantly reducing downtime and the need for frequent, costly replacements.

- Non-Reactive and Food-Safe: 316 stainless steel is inherently non-reactive with the vast majority of food products. This means it will not impart any metallic tastes, alter the food’s color or texture, or leach harmful chemicals into the food stream. This inertness is crucial for preserving the integrity, taste, and safety of the food, ultimately ensuring consumer health and product quality.

Critical Applications of 316 Stainless Steel Angle Bars in the Food Industry

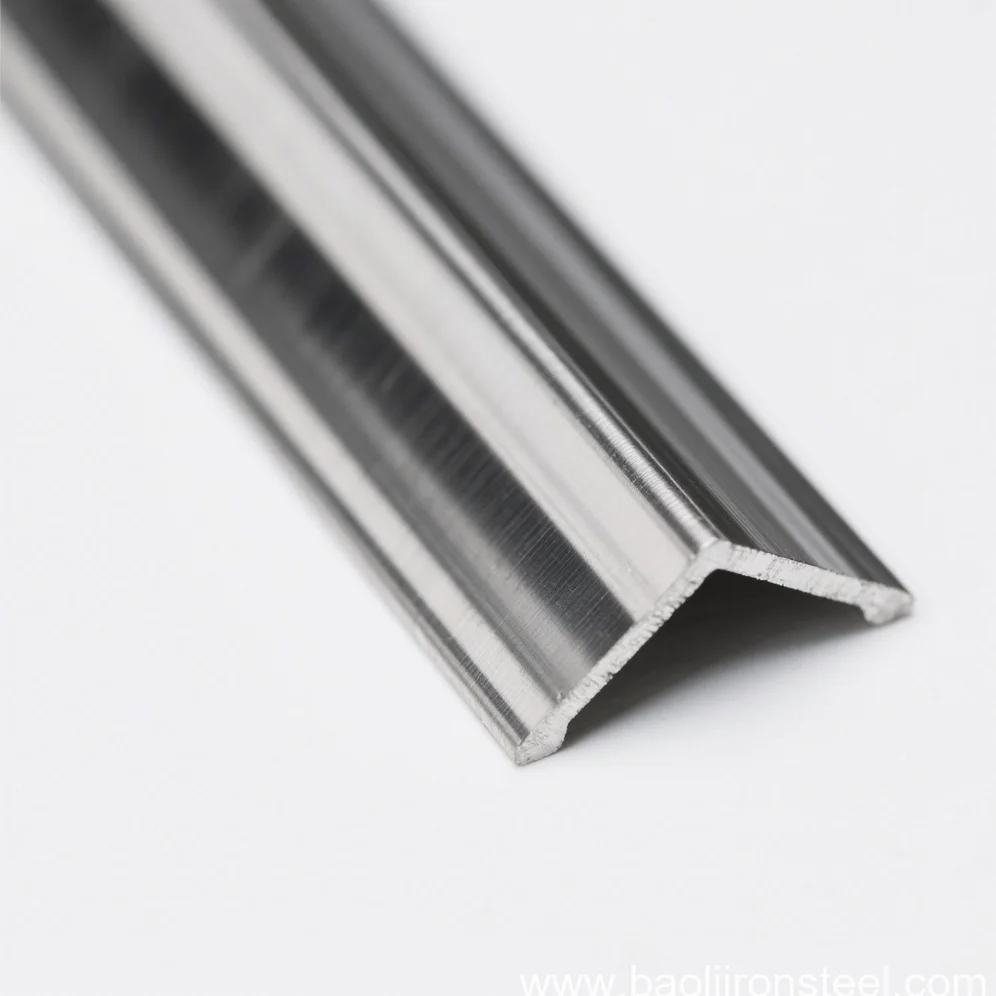

Specifically, angle bars play a quintessential role in structural applications within the food processing environment. Their distinctive L-shaped cross-section provides exceptional rigidity, strength, and load-bearing capabilities, making them indispensable for a wide array of uses where robust, sanitary support is required.

- Structural Frameworks and Supports: They are extensively used to construct robust, sanitary frames for heavy-duty food processing machinery, intricate conveyor systems, sturdy workbenches, and packaging lines. Their inherent strength ensures stable and durable support for even the most demanding equipment and operational loads.

- Equipment Mounting and Bracing: From providing secure mounting points for motors, pumps, and sensors to offering essential bracing for large tanks, vats, and hoppers, 316 SS angle bars deliver reliable support in highly corrosive, humid, and frequently washed-down conditions.

- Edge Protection and Reinforcement: They are frequently incorporated to protect vulnerable edges of walls, floors, and equipment from impact damage caused by moving carts, pallets, or machinery. This not only extends the life of the facility but also prevents accumulation points for grime and bacteria.

- Custom Fabrications and Fixtures: The excellent weldability and formability of 316 stainless steel allow for easy cutting, bending, and fabrication of angle bars into highly customized components required for specific food processing lines, shelving units, or access platforms. This versatility ensures a perfect, compliant fit for unique operational needs.

Why BaoLi Iron & Steel Co.,Ltd is Your Trusted Partner for 316 Stainless Steel Solutions

When selecting critical materials like 316 stainless steel angle bars for the demanding food industry, partnering with a reliable, experienced, and quality-focused manufacturer is paramount. At BaoLi Iron & Steel Co.,Ltd, we understand the specific and uncompromised demands of this sector. As a leading steel manufacturer based in China, we are not just a supplier; we are dedicated to providing premium quality steel products and comprehensive solutions to our global clients, ensuring your projects consistently meet the highest international standards for safety, hygiene, and performance.

Our Unwavering Commitment to Excellence for the Food Industry:

- Unmatched Quality Assurance: We implement an exceptionally stringent quality control system at every stage of production. This meticulous process ensures that all our stainless steel bars, including the crucial 316-grade angle bars, meet and exceed the most rigorous industry standards. Our core philosophy is to achieve 100% customer satisfaction, a benchmark we relentlessly strive for in every single delivery.

- Precision Customization at Its Core: Recognizing that the food industry often requires highly specific and unique specifications for its infrastructure and machinery, we offer comprehensive customized services. We possess the capability to precisely tailor the dimensions, specifications, and performance characteristics of 316 stainless steel angle bars to perfectly match your project’s individual needs, ensuring optimal fit, function, and compliance for your specific processing line or facility.

- Expert Technical Support and Guidance: Our highly experienced team of professional engineers and metallurgists provides invaluable technical guidance. We assist you with optimal material selection, application strategies, and best practices. This ensures you leverage the full potential of 316 stainless steel angle bars to overcome your unique food processing challenges, from design to implementation.

- Global Reach with Dedicated Service: With a robust global service footprint, BaoLi Iron & Steel Co.,Ltd efficiently manages the entire supply chain process, from the initial production phase and quality inspection to secure transportation and comprehensive contract management. We ensure a seamless and highly efficient delivery, no matter where your food industry operations are located around the world.

Conclusion: Investing in Uncompromised Durability and Safety

Choosing 316 stainless steel angle bars for your food industry applications is far more than just meeting a specification; it represents a strategic investment in long-term durability, operational efficiency, and, most critically, absolute food safety. Their unparalleled resistance to corrosion, ease of cleaning, and inherent robust strength make them an exceptional, almost indispensable, choice for creating hygienic, reliable, and compliant food processing environments that stand the test of time and stringent regulations.

At BaoLi Iron & Steel Co.,Ltd, we pride ourselves on being a professional and consistently reliable partner, steadfastly dedicated to helping your vital projects succeed with our superior quality 316 stainless steel products. We are committed to providing steel solutions that not only meet but exceed the demanding requirements of the global food industry. Contact us today to explore how our expertly tailored solutions and premium stainless steel products can significantly enhance your food industry operations and contribute to your success.