From architectural marvels to household essentials, the demand for premium-quality materials like 201 stainless steel is ever-increasing. Our team, a leading stainless steel sheet manufacturer with a focus on 8K finish durability, is dedicated to advancing this field. Let’s explore how we achieve these high-gloss, long-lasting surfaces.

Understanding 201 Stainless Steel: A Brief Overview

Known for its exceptional balance of cost and quality, 201 stainless steel remains a cornerstone in various industries. With higher manganese and lower nickel content than the 300 series, it offers robust corrosion resistance and mechanical properties suitable for demanding applications like kitchenware and automotive detailing.

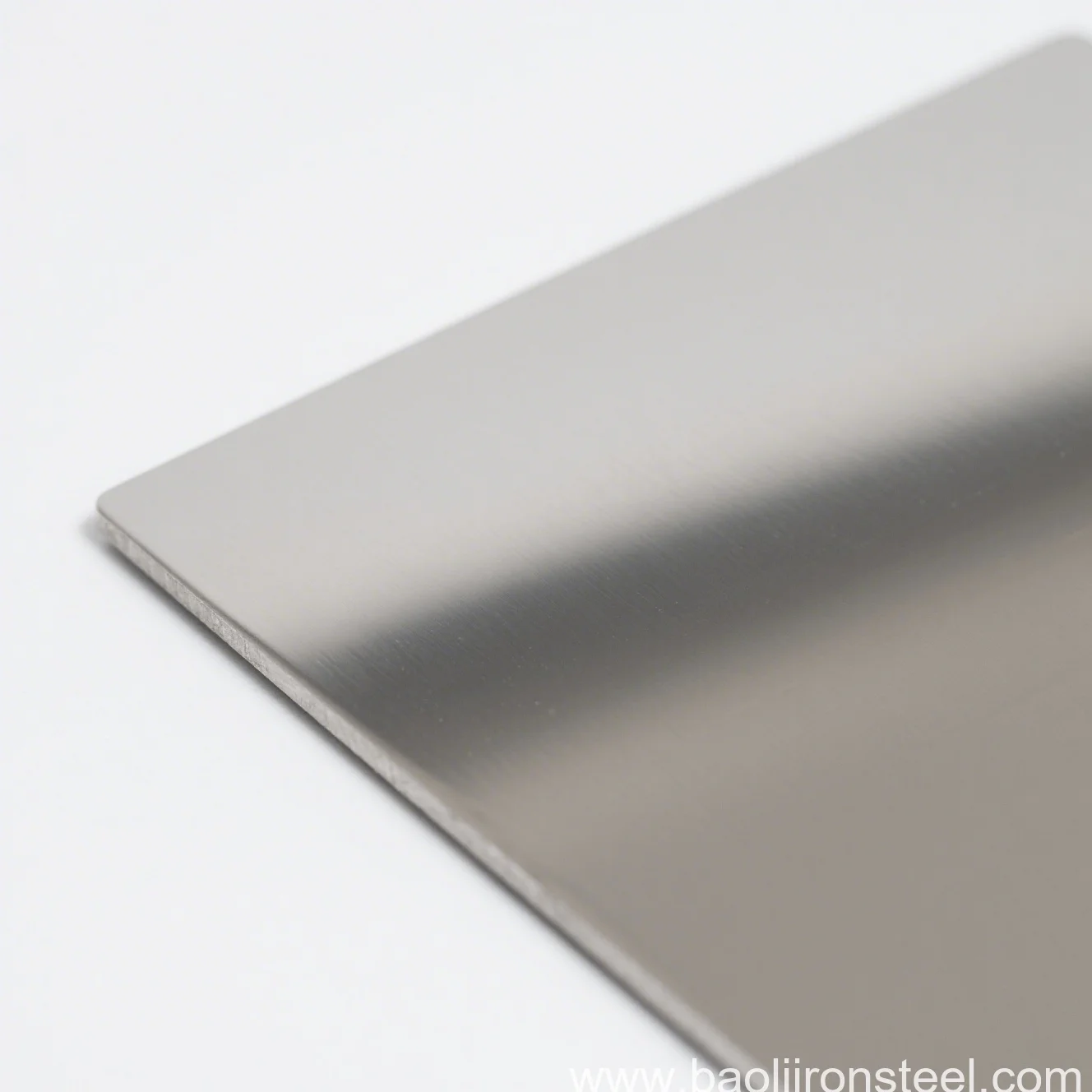

The 8K Finish: A Reflection of Excellence

Achieving an 8K grade finish requires precision. After cold-rolling to a 6K surface, multiple polishing stages create a mirror-like finish. This meticulous process ensures surface defects are minimized, leading to visually stunning and durable products that withstand daily wear.

Ensuring Durability: Beyond Mirror Sheens

Durability goes beyond appearance. Our rigorous in-house tests, including chemical resistance and scratch tests, validate our 201 grade stainless-steel sheets. We evaluate factors such as:

- Impact protection

- Corrosion resistance in varied environments

- Thermal cycle performance

- Abrasion resistance over time

Partnering with BaoLi: The Industry Difference-Maker

BaoLi Iron & Steel Co.,Ltd., a trusted name in global steel manufacturing, goes beyond being an 8K finish supplier. Our advantages include:

- Bespoke solutions for unique 201 stainless steel applications

- Expert quality consultants guiding applications from design to fabrication

- Stringent quality controls ensuring 8K finish integrity matches stringent industry standards

- Global logistics expertise for seamless project timelines

As you seek top-tier 201 stainless steel mirrors sheets, choose a partner who prioritizes durability, quality, and innovation. Explore how BaoLi’s 8K finish solutions can elevate your project, backed by our relentless pursuit of excellence.

201 Stainless Steel Mirror Sheets Manufacturer: How We Ensure 8K Finish Durability – Your Trusted Supplier — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.