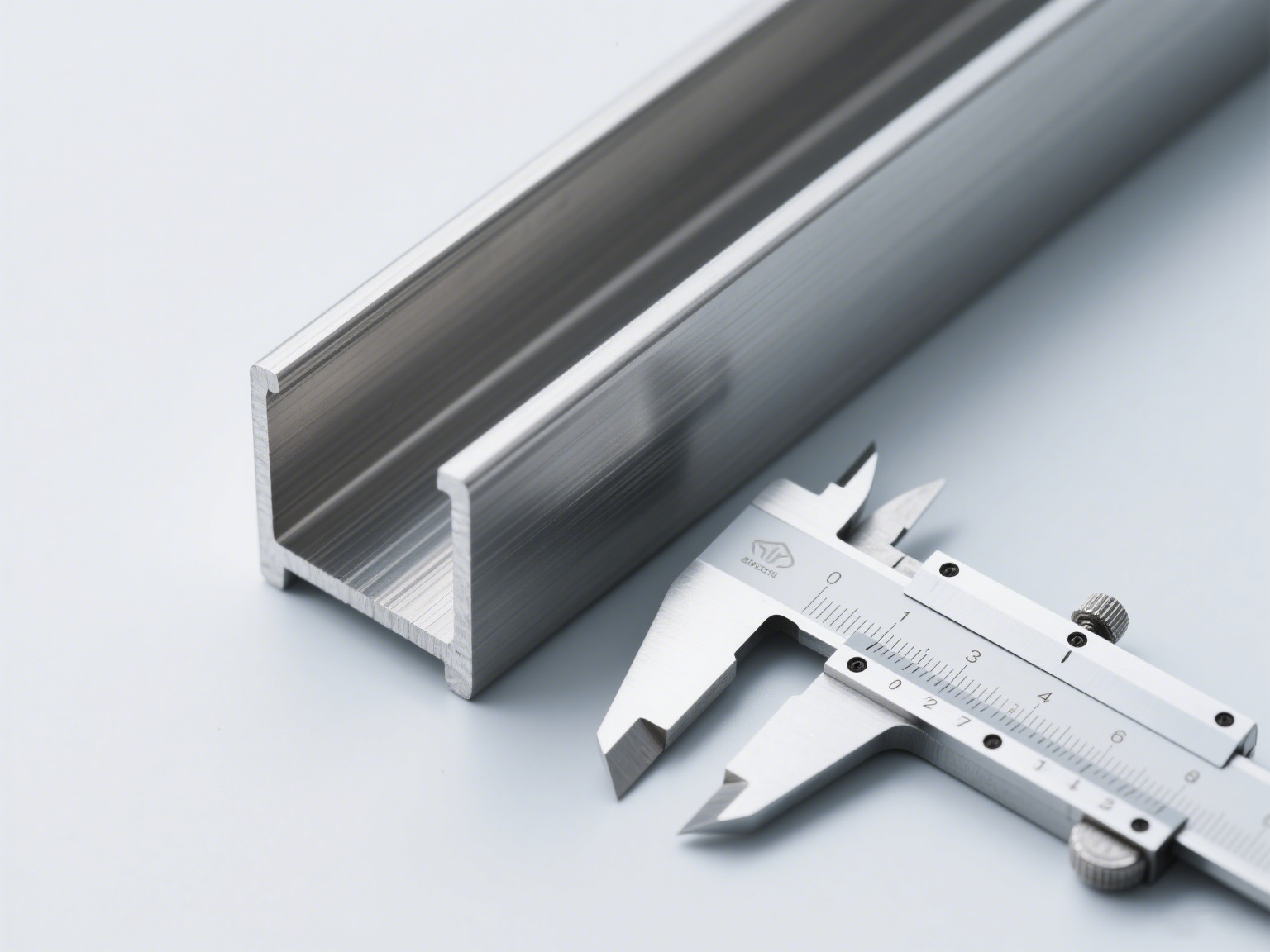

When it comes to durable, cost-effective, and corrosion-resistant structural materials, the 430 Stainless Steel Channel Bar stands out as a preferred choice across various industrial and architectural applications. As a ferritic stainless steel, 430 offers a balanced combination of mechanical strength, formability, and moderate resistance to oxidation and organic acids—making it ideal for environments where high corrosion resistance isn’t the primary requirement but structural integrity and longevity are critical.

At BaoLi Iron & Steel Co., Ltd, we specialize in manufacturing high-quality stainless steel channel bars, including precise grades of 430 stainless steel, tailored to meet global industry standards. Our rigorous production process ensures dimensional accuracy, surface finish consistency, and superior performance under mechanical stress.

What Is 430 Stainless Steel?

430 stainless steel is part of the ferritic family of stainless steels, primarily composed of 16–18% chromium with minimal nickel content. This composition provides good resistance to atmospheric corrosion and stress corrosion cracking, especially in mildly aggressive environments such as indoor settings or non-marine outdoor installations. While not as corrosion-resistant as 304 or 316 grades, 430 offers a compelling cost advantage without sacrificing essential durability.

Key Properties of 430 Stainless Steel Channel Bar

| Property | Value / Description |

|---|---|

| Chromium Content | 16–18% |

| Nickel Content | None (trace only) |

| Tensile Strength | ≥ 450 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 22% |

| Magnetic Properties | Ferromagnetic (magnetic) |

| Weldability | Limited – requires pre/post-weld treatment |

Common Applications of 430 Stainless Steel Channel Bar

Due to its structural strength and moderate corrosion resistance, the 430 stainless steel channel bar is widely used in both industrial and commercial sectors. Some common applications include:

-

Building and Construction: Used in window frames, roof supports, cladding frameworks, and interior structural reinforcements where exposure to moisture is limited. -

Automotive Trim and Components: Employed in exhaust systems, trim moldings, and underbody parts due to heat resistance and aesthetic finish. -

Industrial Equipment: Suitable for tanks, ducting, and processing machinery operating in non-corrosive chemical environments. -

Household Appliances: Frequently chosen for washing machines, refrigerators, and range hoods due to formability and cost-efficiency.

Why Choose BaoLi Iron & Steel for Your 430 Stainless Steel Channel Bar Needs?

As a trusted name in the global steel market, BaoLi Iron & Steel Co., Ltd delivers premium 430 stainless steel channel bars engineered for reliability and performance. Our products undergo stringent quality checks from raw material sourcing to final dispatch. We also offer full customization options—including length, thickness, width, and surface treatment—to align precisely with project specifications.

Whether you’re working on large-scale infrastructure or specialized equipment manufacturing, our team provides end-to-end support—from technical consultation to logistics coordination. With a commitment to 100% customer satisfaction, we ensure timely delivery and consistent product excellence.

To learn more about our range of stainless steel channel bars or request a customized quote, visit our product page today.

430 Stainless Steel Channel Bar: All You Need to Know About Its Durability and Applications — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.