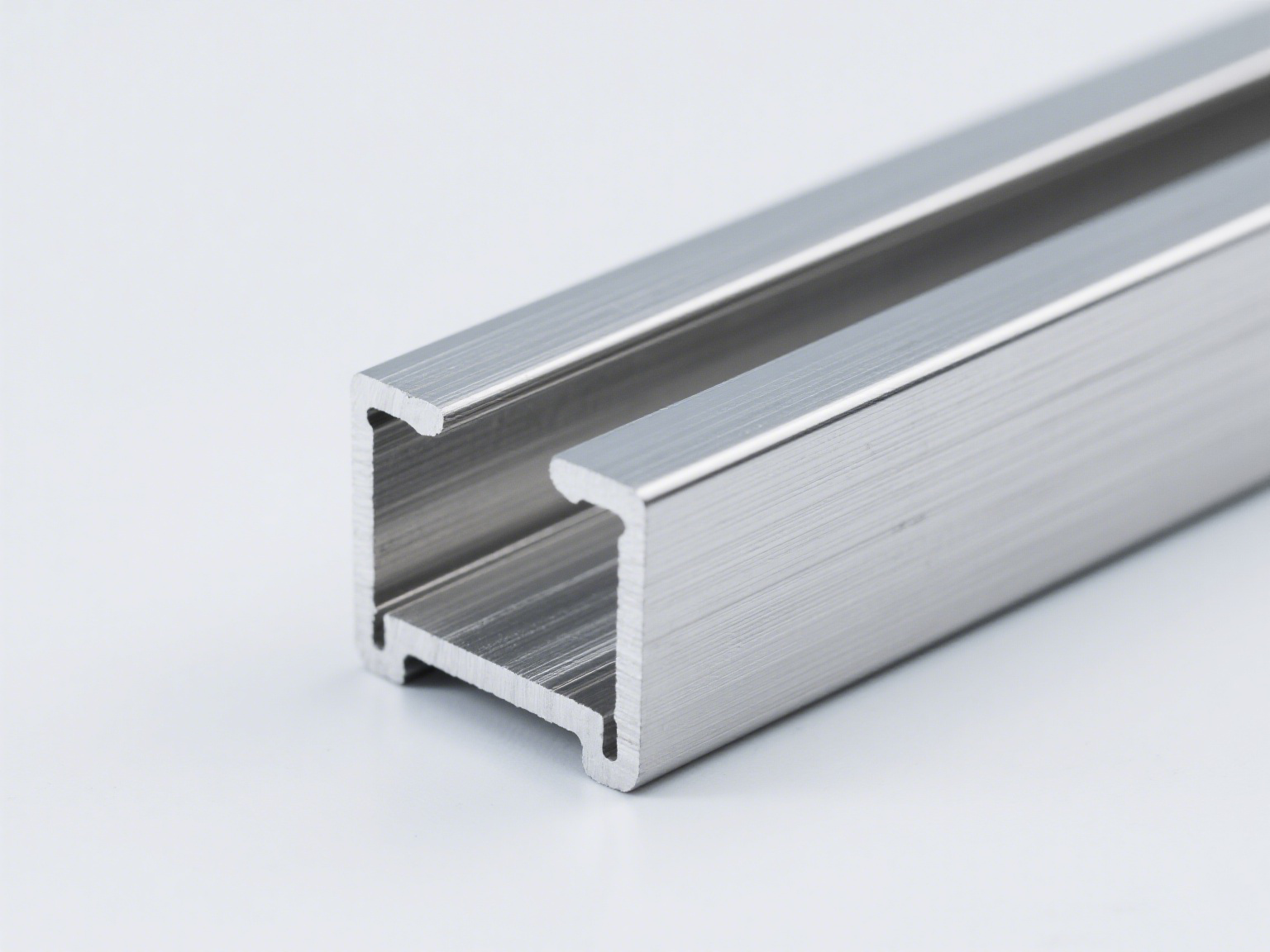

In the construction and operation of chemical processing plants, material selection is one of the most critical factors influencing long-term safety, efficiency, and cost-effectiveness. Among the various structural materials available, stainless steel channel bar has emerged as a premier choice due to its exceptional resistance to corrosive environments, particularly those involving exposure to acids, alkalis, and high-temperature chemical vapors. This article explores the technical advantages, chemical resistance performance, and real-world applications of stainless steel channel bars in chemical plants, with a focus on how products like those offered by BaoLi Iron & Steel Co., Ltd meet the rigorous demands of the chemical processing industry.

Chemical plants operate under extremely aggressive conditions where structural components are constantly exposed to corrosive media such as sulfuric acid, hydrochloric acid, nitric acid, and chlorides. Ordinary carbon steel beams or rolled sections would deteriorate rapidly in such environments, leading to structural weakening, safety risks, and frequent maintenance cycles. In contrast, stainless steel channel bars—especially those made from austenitic grades like 304, 304L, 316, and 316L—exhibit outstanding resistance to both general and localized corrosion. This makes them an ideal material for support frames, walkways, platform structures, and equipment mounting systems in processing units.

One of the key advantages of using stainless steel channel bar in chemical environments is its passive chromium oxide layer. When exposed to oxygen, stainless steel forms a thin, invisible, yet highly adherent layer of chromium oxide on its surface. This layer acts as a protective barrier, preventing further oxidation and inhibiting chemical attack from acidic or saline environments. Even if the surface is scratched or mechanically damaged, the layer can self-repair in the presence of oxygen—a property known as “repassivation”—which is essential for maintaining integrity in continuous operation facilities.

At BaoLi Iron & Steel Co., Ltd, we specialize in manufacturing precision-engineered stainless steel channel bars designed specifically for harsh industrial environments. Our production process adheres to international standards such as ASTM A276, ASTM A484, and JIS G4305, ensuring consistent chemical composition, mechanical strength, and dimensional accuracy. With options spanning grade 304/304L for mild acid exposure and 316/316L for high-chloride or aggressive chemical zones, our product range supports customized solutions tailored to specific plant requirements.

Typical Technical Specifications of Stainless Steel Channel Bars

| Grade | Cr (%) | Ni (%) | Mo (%) | Typical Corrosion Resistance |

|---|---|---|---|---|

| 304 / 304L | 18–20 | 8–10.5 | – | Good resistance to nitric acid, organic acids |

| 316 / 316L | 16–18 | 10–14 | 2–3 | Excellent resistance to chlorides, sulfuric & acetic acids |

The addition of molybdenum in 316-grade stainless steel significantly enhances pitting and crevice corrosion resistance—critical in environments where chloride-induced stress cracking is a major risk. This makes 316L stainless steel channel bars particularly suitable for applications in fertilizer production, petrochemical refining, and wastewater treatment systems within chemical complexes.

Beyond chemical resistance, stainless steel channel bars also deliver superior mechanical performance. They maintain structural integrity at elevated temperatures (up to 870°C intermittent use), resist thermal expansion deformation, and offer excellent weldability. These characteristics allow for secure integration into complex support systems, ladder frames, and reactor enclosures. Moreover, the smooth surface finish reduces particulate buildup and facilitates cleaning—important in maintaining hygiene and compliance in pharmaceutical or fine chemical units.

BaoLi Iron & Steel’s commitment to quality ensures every batch of stainless steel channel bar undergoes rigorous testing, including intergranular corrosion tests (per ASTM A262), tensile strength verification, and non-destructive examination. With global logistics support and expert technical consultation, we enable seamless material integration into your chemical plant infrastructure. Whether you require standard sizes or fully customized profiles, our team delivers reliable, high-performance solutions backed by decades of metallurgical expertise.

For project engineers and procurement managers seeking durable, low-maintenance structural components, investing in high-grade stainless steel channel bars is not just a material decision—it’s a strategic move toward operational sustainability. Visit our product page to explore available dimensions, grades, and customization options today.

Key Specifications

- Standards and grades

- Dimensions and tolerances

- Surface finish

- Certificates (MTC)

Applications

Construction, machinery, energy and general fabrication — match material and finish to the operating environment.