When selecting structural steel components for long-term durability, especially in environments exposed to moisture, chemicals, or weather fluctuations, the choice between stainless steel channel bar and galvanized channel becomes critical. Both offer robust corrosion protection, but their performance, cost, and application suitability differ significantly. Understanding these differences helps engineers, contractors, and procurement specialists make informed material decisions for projects in construction, infrastructure, or industrial manufacturing.

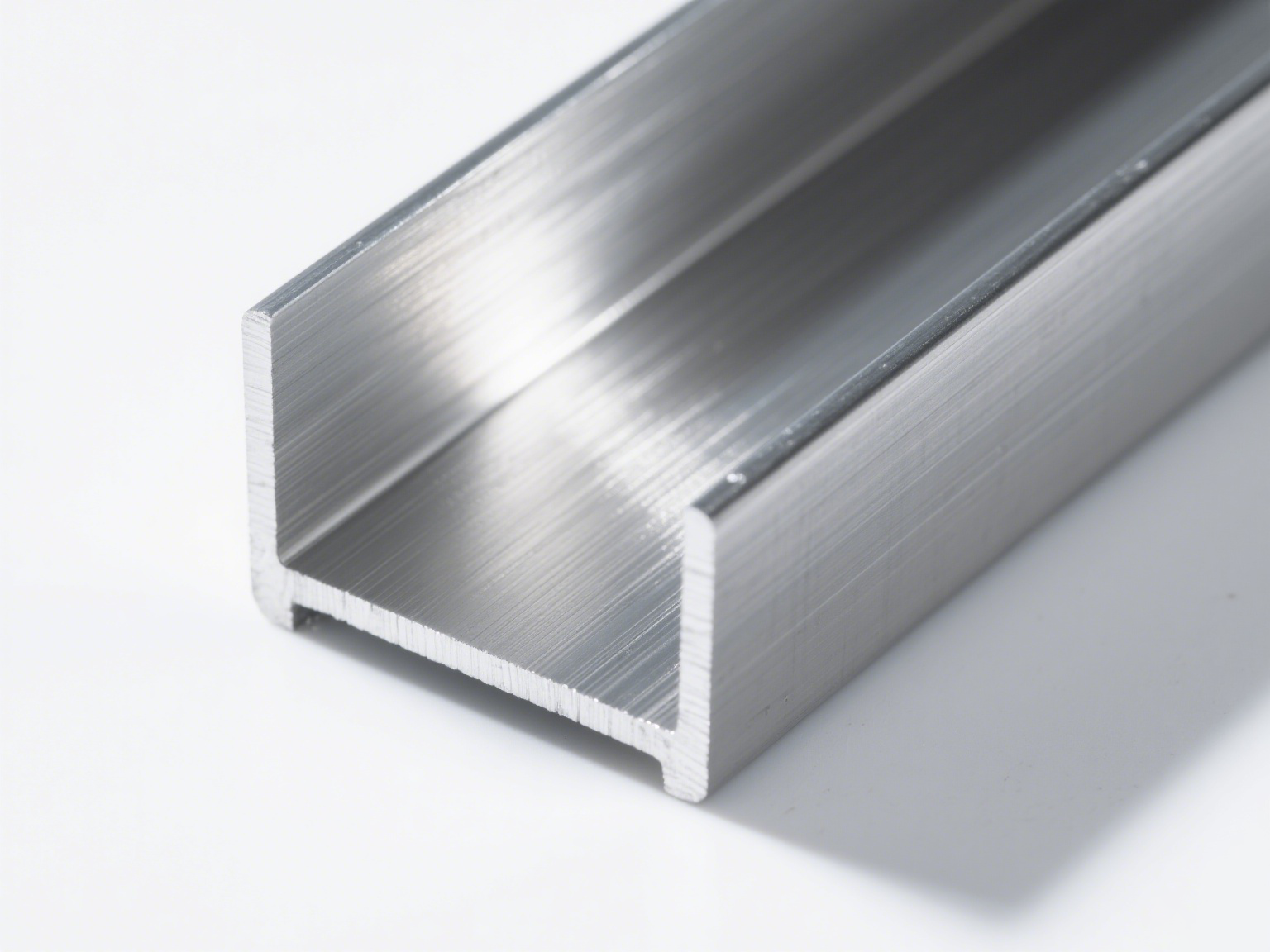

Stainless steel channel bars derive their corrosion resistance from a high chromium content—typically 10.5% or more—which forms a passive oxide layer on the surface. This layer self-repairs in the presence of oxygen, offering continuous protection even when scratched. In contrast, galvanized channels are made from carbon steel coated with a layer of zinc through hot-dip galvanization. The zinc acts as a sacrificial anode, corroding before the underlying steel does. While both methods are effective, the mechanisms and long-term behavior vary.

Corrosion Resistance Performance in Different Environments

In marine or coastal environments, where saltwater exposure accelerates corrosion, stainless steel channel bar outperforms galvanized steel significantly. The chloride ions in salt air can penetrate and degrade the zinc coating over time, leading to base steel corrosion. Stainless steel, particularly grades 304 and 316, maintains integrity for decades in such conditions due to their superior resistance to pitting and crevice corrosion.

Galvanized steel performs well in mild to moderate atmospheric conditions, such as rural or urban settings. The typical galvanized coating thickness (50–100 microns) can provide 30–50 years of service, depending on environmental aggressiveness. However, in acidic or high-humidity industrial zones, the zinc layer may deplete faster, requiring additional maintenance or replacement.

Mechanical and Structural Properties Comparison

| Property | Stainless Steel Channel Bar | Galvanized Channel |

|---|---|---|

| Yield Strength (MPa) | ≥ 210 (Grade 304) | ≥ 250 (Typical carbon steel) |

| Tensile Strength (MPa) | ≥ 515 (Grade 304) | ≥ 400 |

| Corrosion Mechanism | Passive oxide layer (self-healing) | Sacrificial protection (zinc coating) |

| Service Life (Coastal) | 50+ years | 10–20 years |

| Maintenance Needs | Minimal | Periodic inspection, recoating possible |

As shown, while galvanized channels offer higher yield strength in some grades, stainless steel delivers superior longevity in corrosive conditions with minimal maintenance. This makes stainless steel channel bars ideal for critical infrastructure like bridges, offshore platforms, or wastewater treatment plants where failure risk is high.

Cost and Lifecycle Considerations

Upfront, galvanized channels are generally 30–50% less expensive than stainless steel counterparts. However, lifecycle cost analysis often favors stainless steel due to reduced maintenance, longer service life, and lower replacement frequency. For long-term projects, especially those in harsh environments, the initial investment in stainless steel pays off over decades.

At BaoLi Iron & Steel Co., Ltd, we provide high-grade stainless steel channel bars manufactured to ASTM A276 and AISI standards, available in custom lengths and finishes. Our quality assurance system ensures every product meets international corrosion resistance benchmarks.

With global logistics support and engineering consultation, BaoLi Iron & Steel empowers clients to choose the right corrosion protection strategy. Whether it’s selecting between stainless and galvanized channels or customizing cross-sections, our technical team offers tailored guidance to optimize performance and cost-efficiency.

Stainless Steel Channel Bar vs Galvanized Channel: Corrosion Protection Comparison — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.