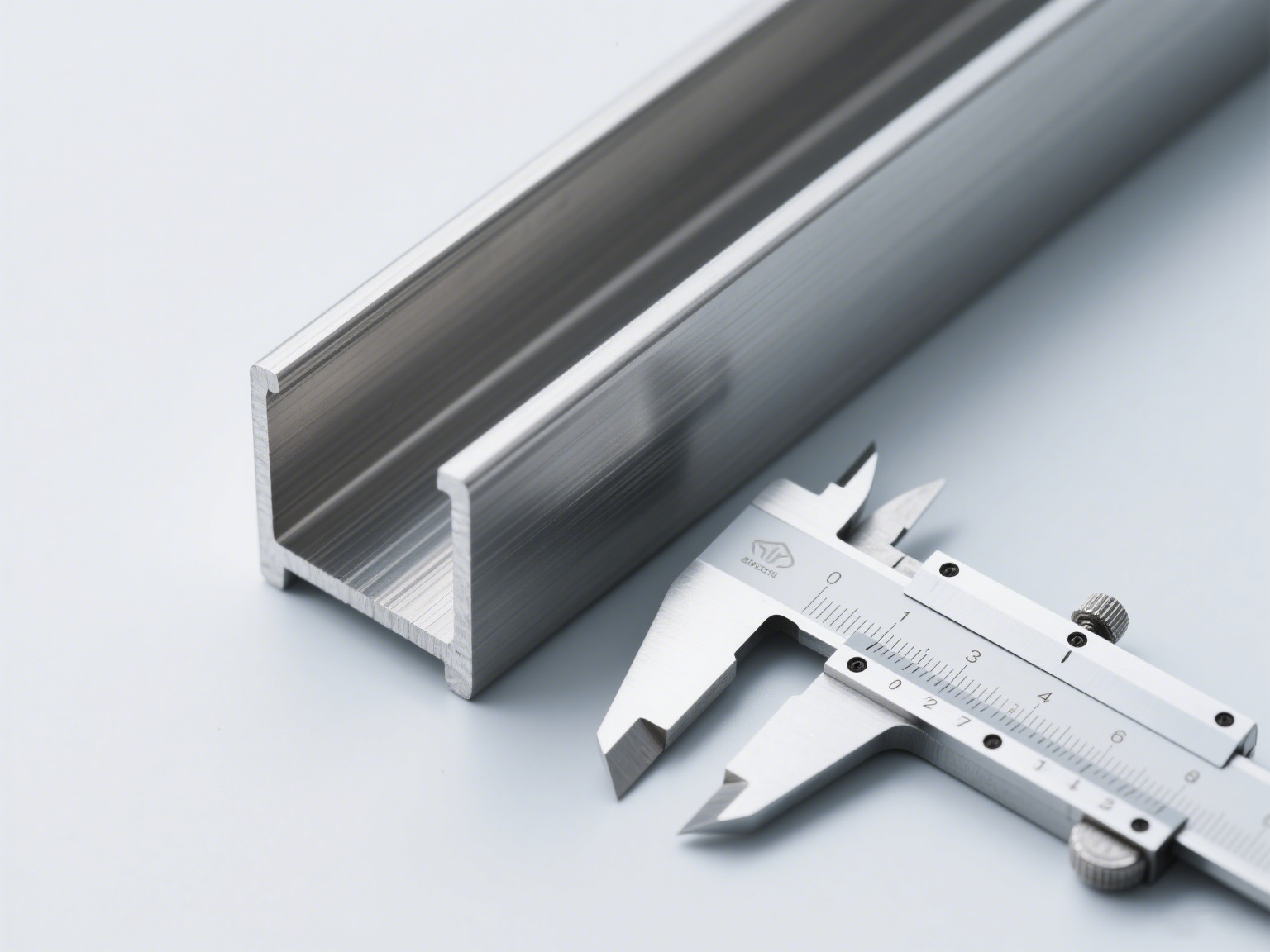

Stainless steel channel bars are widely used in construction, industrial frameworks, transportation systems, and architectural applications due to their excellent strength-to-weight ratio, corrosion resistance, and aesthetic appeal. Proper fabrication techniques—such as bending, punching, and shaping—are essential to maintain the structural integrity and performance of these components. This guide delves into best practices for fabricating stainless steel channel bars, with insights from BaoLi Iron & Steel Co., Ltd., a leading Chinese manufacturer committed to quality and innovation in steel production.

One of the most critical aspects of working with stainless steel channel sections is understanding their material behavior under stress. Unlike carbon steel, stainless steel has higher work-hardening rates, which means it strengthens as it is bent or formed. While beneficial for durability, this characteristic requires careful control during fabrication to prevent cracking or distortion. Using appropriate tooling, maintaining consistent feed rates, and applying proper lubrication can significantly improve results.

Cold Bending Techniques

Cold bending is a common method for shaping stainless steel channel bars without altering their metallurgical properties. The process typically involves roll benders or press brakes designed specifically for high-tensile materials. For accurate outcomes, it’s crucial to calculate springback—the tendency of metal to revert slightly after bending—and compensate accordingly during setup.

At BaoLi Iron & Steel Co., Ltd., our engineers use precision-controlled CNC press brakes capable of handling stainless steel thicknesses ranging from 2 mm to 12 mm, ensuring tight tolerances (±0.5° angular accuracy) even on complex profiles. We recommend using mandrel-assisted bending for tighter radii to minimize cross-sectional deformation.

Punching and Hole Preparation

Punching holes in stainless steel channel bars must be executed with sharp tooling and proper clearance—typically 10–15% of the material thickness—to avoid burr formation and edge cracking. High-speed steel (HSS) or carbide-tipped punches are ideal for repeated operations due to their wear resistance.

Our production line at BaoLi Iron & Steel integrates automatic punch presses with laser-guided positioning systems, enabling hole accuracy within ±0.2 mm. This level of precision is vital for assembly in modular construction and mechanical frameworks where alignment is critical.

Forming and Shaping Considerations

Beyond basic bending and punching, some applications require intricate shaping such as tapering, flaring, or multi-radius curving. These operations demand specialized dies and incremental forming techniques. Hydraulically driven roll forming machines provide the necessary control over gradual shape transitions.

| Parameter | Value / Range | Application Note |

|---|---|---|

| Material Grade | AISI 304, 316, 321 | Suitable for corrosive environments |

| Thickness Range | 2–12 mm | Compatible with heavy-duty fabrication |

| Min. Bend Radius | 2× material thickness | Prevents cracking and warping |

| Tool Clearance (Punching) | 10–15% of thickness | Ensures clean hole edges |

Heat treatment following extensive forming may be required to relieve internal stresses, especially in load-bearing structures. Solution annealing at temperatures between 1010°C and 1120°C, followed by rapid quenching, helps restore corrosion resistance compromised by cold-working.

As a trusted name in the global steel industry, BaoLi Iron & Steel Co., Ltd. combines advanced manufacturing capabilities with rigorous quality assurance protocols. Every stainless steel channel bar we produce undergoes non-destructive testing (NDT), dimensional inspections, and chemical composition verification to meet international standards like ASTM A276 and EN 10088.

Our team also provides comprehensive technical support to help clients select the optimal grade and fabrication method based on service environment and structural requirements. From small custom batches to large-scale industrial orders, we ensure timely delivery and consistent product performance.

With a customer-centric approach and a commitment to reliability, BaoLi Iron & Steel continues to deliver high-performance stainless steel solutions that stand the test of time.