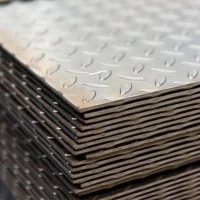

Description

The Right Plate for Tough Jobs – We’ve Been There

Ever had a stainless steel plate fail at the worst possible moment? We’ve seen it happen – a chemical plant leak due to pitting corrosion, or a food processing line shutdown because of surface contamination. That’s why we don’t just sell ASTM A240 certified stainless steel plates – we engineer them with real-world failures in mind. Our plates have held up in offshore platforms facing salt spray for 15+ years and in pharmaceutical cleanrooms where surface finish matters as much as composition.

What makes our plates different? It starts with the melt. We use vacuum degassing on our 316L and 321 grades to reduce inclusions – a small detail that pays off in high-stress applications. The chromium (16-26%) and nickel (6-22%) content isn’t just numbers on a spec sheet; it means your plates will resist chloride stress corrosion cracking where others fail. A customer in the Gulf of Mexico reported zero pitting after 8 years using our 316L plates with 2.5% Mo – that’s the kind of feedback that keeps us refining our process.

Built for Your Exact Needs

- Grade selection: We keep 12 standard grades in stock, from the workhorse 304 for kitchen equipment to 2205 duplex for high-pressure chemical vessels. The 310S we supply has 24-26% chromium, ideal for heat exchangers running at 1100°C.

- Precision matters: Our laser-cut edges stay burr-free down to 0.8mm thickness. For critical applications, we can hold ±0.02mm tolerance on thickness – ask about our gauge control system.

- Testing beyond requirements: Every batch gets ultrasonic testing plus optional third-party verification. We once caught a sub-surface laminar defect in 50mm thick 321 plates – it would have been a nuclear plant nightmare.

We’ve learned that “standard” doesn’t always work. Need plates with 1524mm width instead of the usual 1500mm? We’ve modified our rolling schedules for bridge projects where every millimeter counts. Or perhaps you need #4 finish with Ra < 0.5μm for medical applications – we’ve done that too.

As a Chinese mill supplying global projects, we combine competitive pricing with Western-grade QC. Our EN 10204 3.2 certifications are issued by Lloyd’s Register, and we welcome customer audits. When a European shipbuilder needed 800 tons of 316L plates with full traceability, we delivered with material passports for each coil.

Talk to us about your specific challenges – we’ve probably solved something similar before.