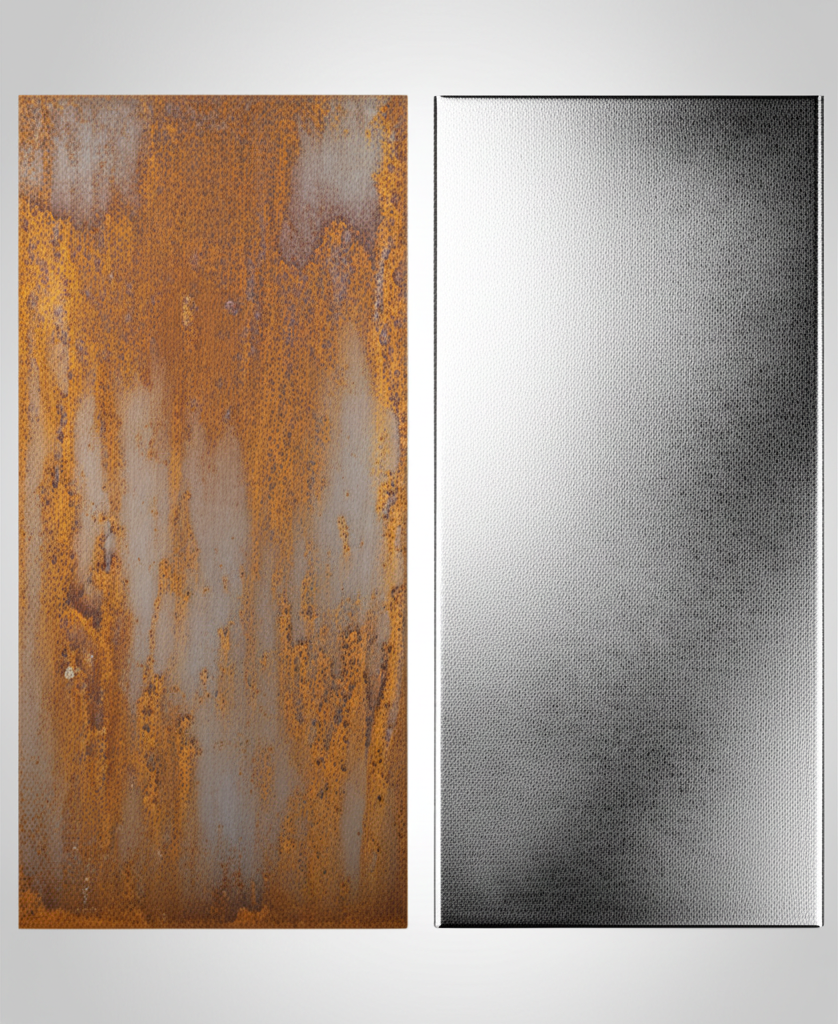

When selecting steel for construction, manufacturing, or infrastructure projects, the debate between carbon steel and galvanized steel often arises. Both materials have distinct properties, advantages, and limitations, particularly in terms of performance and corrosion resistance. This comprehensive comparison delves into their differences, applications, and technical specifications to guide decision-making.

1. Composition and Basic Properties

-

Carbon Steel: Primarily composed of iron and carbon (typically 0.05%–2.0% carbon content), with trace elements like manganese, silicon, and copper. It is categorized into low, medium, and high-carbon steel based on carbon levels.

- Advantages: High tensile strength, cost-effective, and easily machinable.

- Limitations: Prone to rust and corrosion in humid or corrosive environments.

-

Galvanized Steel: A carbon steel substrate coated with a protective layer of zinc (via hot-dip or electro-galvanizing). The zinc layer acts as a sacrificial anode, preventing oxidation.

- Advantages: Exceptional corrosion resistance, longer lifespan, and low maintenance.

- Limitations: Higher upfront cost, potential coating damage during fabrication.

2. Corrosion Resistance: The Key Differentiator

Corrosion is a critical factor in material selection. Here’s how they compare:

| Factor | Carbon Steel | Galvanized Steel |

|—————————|——————————————-|———————————————–|

| Corrosion Mechanism | Rusts when exposed to oxygen and moisture | Zinc layer oxidizes first, protecting steel |

| Lifespan | 5–10 years (unprotected) | 20–50 years (depending on coating thickness) |

| Maintenance | Requires painting or coatings | Minimal maintenance needed |

| Environment Suitability| Indoor/dry environments | Outdoor, marine, or high-humidity areas |

- Galvanized Steel’s Edge: The zinc coating provides cathodic protection, even if scratched. For example, a 55% Al-Zn alloy coating (e.g., Galfan) offers even better corrosion resistance.

- Carbon Steel’s Weakness: Without protective coatings, it degrades rapidly in coastal areas or acidic conditions (pH < 6).

3. Mechanical Performance and Applications

-

Strength and Hardness:

- Carbon steel excels in load-bearing applications due to its high tensile strength (up to 2,000 MPa for high-carbon variants).

- Galvanized steel retains similar mechanical properties but may lose ductility if the zinc layer is excessively thick.

-

Common Applications:

- Carbon Steel:

- Structural beams, automotive components, and cutting tools.

- Example: A36 steel (yield strength: 250 MPa) is widely used in construction.

- Galvanized Steel:

- Outdoor structures (fences, roofs, utility poles), automotive body panels, and HVAC systems.

- Example: G90 galvanized steel (zinc coating: 275 g/m²) is standard for roofing.

- Carbon Steel:

4. Cost Considerations

- Initial Cost: Carbon steel is 30–50% cheaper than galvanized steel.

- Lifetime Cost: Galvanized steel’s corrosion resistance reduces replacement and maintenance expenses, making it cost-effective for long-term projects.

5. Fabrication and Welding Challenges

- Carbon Steel: Easy to weld and cut but requires post-fabrication corrosion treatments (e.g., powder coating).

- Galvanized Steel: Welding releases toxic zinc fumes, requiring ventilation. Cut edges are vulnerable to corrosion unless re-coated.

6. Sustainability and Recyclability

Both steels are 100% recyclable, but galvanized steel’s longevity reduces material waste. However, zinc mining and coating processes have a higher environmental footprint than raw carbon steel.

7. Choosing the Right Material

- Opt for Carbon Steel If:

- Budget is a priority.

- The application is indoor or low-corrosion (e.g., furniture, machinery).

- Opt for Galvanized Steel If:

- Corrosion resistance is critical (e.g., bridges, pipelines, outdoor signage).

- The project requires minimal maintenance over decades.

At Baoli Steel, a leading Chinese steel manufacturer, we specialize in custom carbon and galvanized steel solutions tailored to your project’s specifications. Our ISO-certified facilities produce high-quality products with competitive pricing, including ASTM, EN, and JIS standards. Whether you need precision-cut sheets or large structural beams, our team ensures

Key Specifications

- Standards and grades

- Dimensions and tolerances

- Surface finish

- Certificates (MTC)

Applications

Construction, machinery, energy and general fabrication — match material and finish to the operating environment.