Which Is More Expensive, GI or SS? A Comprehensive Cost Comparison

When evaluating materials for construction, manufacturing, or infrastructure projects, one of the most common questions is: Which is more expensive, GI (Galvanized Iron) or SS (Stainless Steel)? While both materials offer corrosion resistance and structural integrity, their cost structures differ significantly due to raw materials, manufacturing processes, and long-term performance. This expert analysis breaks down the key factors influencing the price of GI versus SS, helping engineers, procurement specialists, and project managers make informed decisions. For high-quality steel products, including both GI and SS variants, visit Baoli Iron & Steel, a trusted supplier with global reach and industry-leading certifications.

Understanding GI (Galvanized Iron): Composition and Manufacturing

Galvanized Iron (GI) refers to carbon steel that has been coated with a protective layer of zinc through a hot-dip galvanizing process. This coating prevents rust and extends the material’s lifespan, especially in outdoor or humid environments. The base material—carbon steel—is relatively inexpensive, and the galvanizing process adds a moderate cost premium.

- Base Material: Low-carbon steel, widely available and cost-effective.

- Coating Process: Hot-dip galvanizing involves immersing steel in molten zinc, forming a metallurgical bond.

- Cost Drivers: Zinc prices, energy consumption during galvanizing, and coating thickness (measured in g/m²).

<

<

Because GI leverages low-cost steel with a protective zinc layer, it is generally less expensive upfront than stainless steel. However, the long-term cost-effectiveness depends on environmental exposure and maintenance needs.

Understanding SS (Stainless Steel): Alloy Composition and Production

Stainless Steel (SS) is an alloy primarily composed of iron, chromium (minimum 10.5%), and often nickel, molybdenum, and other elements. The chromium forms a passive oxide layer that provides inherent corrosion resistance—no additional coating required. Common grades include 304 (austenitic) and 316 (marine-grade).

- Base Alloys: Chromium and nickel are significantly more expensive than zinc or carbon steel.

- Production Complexity: Requires precise alloying, melting in electric arc furnaces, and specialized rolling processes.

- Cost Drivers: Nickel and chromium market prices, energy-intensive manufacturing, and quality control standards.

<

Due to its alloy content and production complexity, stainless steel is inherently more expensive per kilogram than galvanized iron. For premium SS products with consistent quality and traceability, Baoli Iron & Steel offers a wide range of certified stainless steel sheets, coils, and structural sections.

Upfront Cost Comparison: GI vs. SS

Material Cost per Kilogram

On average, the price difference between GI and SS is substantial:

- GI Steel: $0.80 – $1.20 per kg (depending on zinc coating and gauge).

- Stainless Steel (304): $2.50 – $3.50 per kg.

- Stainless Steel (316): $3.50 – $5.00 per kg (due to higher nickel and molybdenum content).

This means stainless steel can be 2.5 to 5 times more expensive than GI on a per-kilogram basis. For large-scale projects, this difference can translate into millions of dollars in material costs.

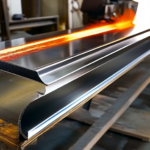

Fabrication and Processing Costs

While GI is cheaper to purchase, it may require additional fabrication steps:

- GI: Can be cut, welded, and formed easily, but post-fabrication galvanizing may be needed if the coating is damaged.

- SS: More challenging to weld and machine due to work-hardening properties, requiring specialized tools and skilled labor—increasing labor and equipment costs.

However, SS does not require post-fabrication coating, reducing long-term processing steps. In high-precision or sanitary applications (e.g., food processing, pharmaceuticals), the higher fabrication cost of SS is often justified by its performance.

Long-Term Cost Analysis: Total Cost of Ownership (TCO)

Corrosion Resistance and Maintenance

While GI is corrosion-resistant, its zinc coating degrades over time—especially in coastal, acidic, or high-salinity environments. Typical lifespan:

- GI: 10–30 years, depending on environment and coating thickness.

- SS (304/316): 50+ years with minimal maintenance.

GI structures often require periodic inspection, repainting, or re-galvanizing, adding to lifecycle costs. In contrast, stainless steel requires little to no maintenance, reducing operational downtime and labor expenses.

Replacement and Downtime Costs

Replacing corroded GI components can be costly due to:

- Project downtime

- Labor for removal and reinstallation

- Disposal of old materials

Stainless steel’s longevity reduces or eliminates these costs. In critical infrastructure (e.g., bridges, water treatment plants), the higher initial investment in SS often results in lower TCO over 20–30 years.

Environmental and Sustainability Factors

Stainless steel is 100% recyclable, with a recycling rate exceeding 90% globally. Its long lifespan reduces resource consumption and waste. GI, while recyclable, has a shorter service life and higher replacement frequency, increasing its environmental footprint.

For projects prioritizing sustainability and ESG (Environmental, Social, and Governance) goals, stainless steel offers a more responsible long-term solution—despite the higher upfront cost.

Application-Specific Cost Considerations

When to Choose GI: Cost-Effective Applications

GI is ideal for:

- Roofing and cladding in inland areas

- Fencing, guardrails, and agricultural structures

- HVAC ducting and electrical conduits

- Projects with limited budgets and moderate environmental exposure

In these cases, the lower initial cost and adequate performance make GI the preferred choice. For reliable GI products with consistent zinc coating, Baoli Iron & Steel provides ASTM and ISO-certified galvanized steel coils and sheets.

When to Choose SS: Performance-Driven Applications

Stainless steel is essential for:

- Marine and coastal structures (use 316 grade)

- Food processing, medical, and pharmaceutical equipment

- Architectural facades and high-end design elements

- Chemical processing and wastewater treatment

Here, the superior corrosion resistance, hygiene, and aesthetic appeal justify the higher cost. SS also maintains structural integrity under extreme temperatures, making it suitable for industrial applications.

Conclusion: Balancing Cost and Performance

The answer to “Which is more expensive, GI or SS?” is clear: Stainless steel is significantly more expensive upfront, typically 2.5 to 5 times the cost of galvanized iron. However, this comparison must go beyond initial price tags.

For short-term, budget-constrained projects in mild environments, GI offers excellent value. But for long-term, high-performance, or corrosive environments, stainless steel delivers superior total cost of ownership through durability, low maintenance, and recyclability.

Ultimately, the decision should be based on:

- Environmental exposure

- Project lifespan

- Maintenance capabilities

- Sustainability goals

- Regulatory or hygiene requirements

For both GI and SS materials, sourcing from a reputable supplier ensures quality, consistency, and compliance. Visit Baoli Iron & Steel to explore a comprehensive range of steel products, technical specifications, and expert support for your next project.