Introduction to Stainless Steel Finishes and Their Industrial Significance

Stainless steel coils are fundamental materials in modern manufacturing, construction, and consumer goods. The surface finish of a stainless steel coil—determined by processes such as annealing, pickling, and mechanical polishing—plays a critical role in its performance, aesthetics, and suitability for specific applications. Among the most widely used finishes are BA (Bright Annealed) and 2B (Cold Rolled, Annealed, and Pickled), each offering distinct surface characteristics, roughness profiles, and functional advantages.

Understanding the differences between BA and 2B finishes is essential for engineers, procurement specialists, and designers aiming to optimize material selection. This guide provides a comprehensive comparison of BA and 2B stainless steel coils, focusing on surface quality, surface roughness, corrosion resistance, and real-world applications.

What Is BA (Bright Annealed) Stainless Steel Coil?

Definition and Manufacturing Process

BA (Bright Annealed) stainless steel is produced by cold rolling the steel to the desired thickness, followed by annealing in a controlled atmosphere—typically a mixture of hydrogen and nitrogen—to prevent oxidation. This process results in a smooth, reflective, and bright surface without the need for subsequent mechanical polishing. The absence of oxygen during annealing ensures a clean, oxide-free surface, enhancing both appearance and corrosion resistance.

The annealing process is critical in achieving the BA finish, as it relieves internal stresses and improves ductility while preserving surface integrity.

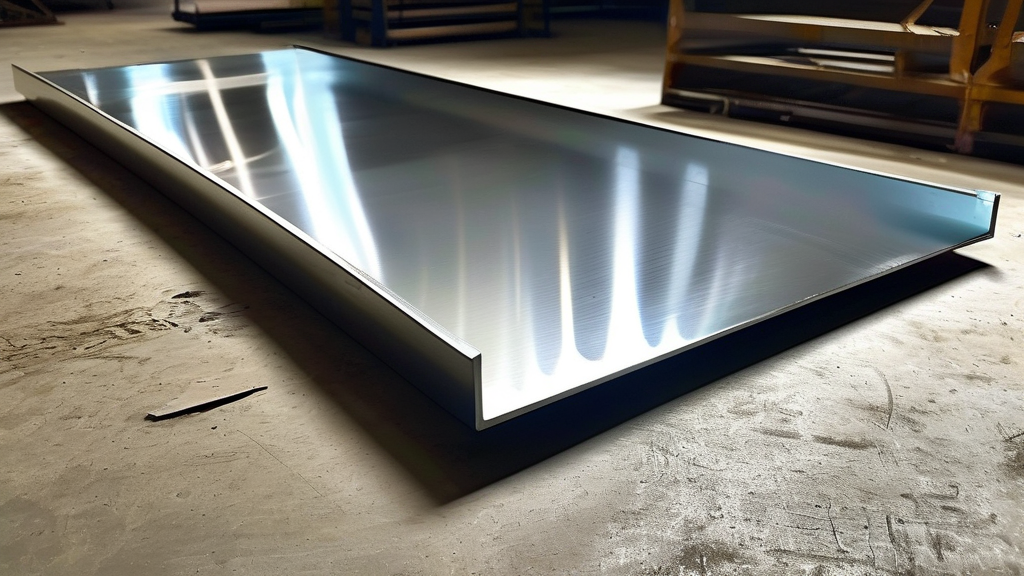

Surface Characteristics and Visual Appearance

The BA finish is characterized by a mirror-like, highly reflective surface with minimal grain structure visibility. It exhibits a uniform, bright appearance that is often described as “luster” or “glossy.” This aesthetic quality makes BA ideal for applications where visual appeal is paramount.

Unlike mechanically polished finishes, BA does not involve grinding or buffing, which reduces the risk of surface contamination and ensures consistent quality across large coil lengths.

Surface Roughness (Ra) of BA Finish

The average surface roughness (Ra) of BA stainless steel typically ranges from 0.1 to 0.3 µm, depending on the alloy (e.g., 304, 316) and processing conditions. This low roughness contributes to excellent cleanability, reduced friction, and superior performance in hygienic environments.

What Is 2B (Cold Rolled, Annealed, and Pickled) Stainless Steel Coil?

Definition and Manufacturing Process

The 2B finish is one of the most common stainless steel surface treatments, defined by ASTM A480 and widely used in industrial and architectural applications. It is produced by cold rolling the steel, followed by annealing in air (which forms a thin oxide layer), and then pickling in an acid solution (typically nitric and hydrofluoric acid) to remove the oxide scale.

This pickling process ensures a clean, matte surface with a slightly textured appearance. Unlike BA, 2B is not polished and retains a dull, non-reflective finish.

Surface Characteristics and Visual Appearance

The 2B finish has a matte, semi-bright appearance with a fine, uniform grain structure. It lacks the high reflectivity of BA but offers excellent dimensional stability and is more cost-effective to produce. The surface is smooth to the touch but not mirror-like, making it suitable for applications where glare or high reflectivity is undesirable.

Surface Roughness (Ra) of 2B Finish

The average surface roughness (Ra) of 2B stainless steel ranges from 0.4 to 0.8 µm, significantly higher than BA. This increased roughness can affect friction, cleanability, and adhesion of coatings or adhesives. However, the 2B finish still meets most industrial standards for smoothness and is often used as a base for further processing (e.g., polishing, coating).

Key Differences Between BA and 2B Stainless Steel Coils

Surface Reflectivity and Aesthetics

- BA: High reflectivity, mirror-like finish; ideal for decorative and architectural applications.

- 2B: Matte, semi-bright finish; better suited for industrial and structural uses where aesthetics are secondary.

Surface Roughness and Cleanability

- BA: Lower Ra (0.1–0.3 µm) enables easier cleaning, reduced bacterial adhesion, and superior performance in food, pharmaceutical, and medical applications.

- 2B: Higher Ra (0.4–0.8 µm) may trap contaminants more readily, requiring more rigorous cleaning protocols in hygienic environments.

Corrosion Resistance

Both finishes offer excellent corrosion resistance due to the passive chromium oxide layer on stainless steel. However, BA provides marginally better corrosion resistance in aggressive environments because the bright annealed surface is free of oxide scale and micro-crevices that could harbor corrosive agents. The absence of pickling residues in BA also reduces the risk of localized corrosion.

Cost and Production Efficiency

- 2B is generally less expensive to produce due to simpler processing (air annealing and pickling).

- BA requires a controlled atmosphere furnace, increasing energy and operational costs. However, it eliminates the need for post-annealing polishing, which can offset costs in high-volume decorative applications.

Applications of BA and 2B Stainless Steel Coils

Applications of BA Finish

- Architectural and Interior Design: Elevator panels, decorative trims, kitchen backsplashes, and signage.

- Medical and Pharmaceutical Equipment: Surgical instruments, cleanroom components, and medical device housings where surface smoothness and sterility are critical.

- Food and Beverage Processing: Tanks, conveyors, and processing equipment requiring high cleanability and resistance to organic acids.

- Consumer Electronics: High-end appliances, smartphone frames, and automotive trim where a premium finish is desired.

Applications of 2B Finish

- Industrial Equipment: Structural components, heat exchangers, and chemical processing tanks.

- Construction and Infrastructure: Roofing, cladding, and support structures where cost-efficiency and durability are prioritized.

- Automotive and Transportation: Exhaust systems, chassis components, and fuel tanks.

- General Fabrication: Base material for further processing such as polishing to achieve a #4 or #8 finish, or for painting and coating.

Choosing Between BA and 2B: A Decision Framework

When selecting between BA and 2B stainless steel coils, consider the following factors:

- Aesthetic Requirements: Choose BA for high-visibility, decorative applications.

- Hygiene and Cleanability: BA is superior in food, medical, and pharmaceutical settings.

- Budget Constraints: 2B offers a cost-effective solution for structural and industrial uses.

- Post-Processing Needs: 2B is often used as a substrate for mechanical polishing or coating; BA is typically used as-is.

- Environmental Exposure: In highly corrosive environments, BA may offer longer service life due to its cleaner surface.

Conclusion: Matching Finish to Function

The choice between BA and 2B stainless steel coils is not merely aesthetic—it is a strategic decision that impacts performance, maintenance, and lifecycle cost. While BA excels in applications demanding high surface quality, low roughness, and visual appeal, 2B remains the workhorse of industrial stainless steel, offering reliability, affordability, and versatility.

By understanding the nuances of surface finish, roughness, and application-specific requirements, engineers and designers can make informed decisions that align with both technical and economic objectives. As stainless steel continues to evolve, finishes like BA and 2B will remain foundational to innovation across industries.

Related Products and Next Steps

Use these links to compare options and send RFQ with complete specs.