Introduction to Steel Cutting Technologies and Cost Considerations

Why Cutting Method Matters for Project Budgeting

Selecting the appropriate steel cutting method is a critical decision that directly impacts project timelines, material utilization, and overall fabrication costs. In industrial and structural applications, even minor differences in cost per inch can translate into significant savings or overruns over large production runs. Understanding the nuances of each cutting technology enables engineers, procurement managers, and fabricators to align technical requirements with financial objectives.

Key Factors Influencing Cost Per Inch in Steel Fabrication

Several variables determine the true cost per inch of steel cutting: equipment depreciation, energy consumption, labor requirements, consumable usage (e.g., nozzles, abrasives), maintenance frequency, and cutting speed. Additionally, factors such as kerf width (the width of material removed during cutting), edge quality, and post-processing needs influence effective cost. A holistic evaluation—beyond just hourly machine rates—is essential for accurate budgeting.

Overview of Laser, Waterjet, and Plasma Cutting Methods

Three dominant technologies power modern steel fabrication: laser, waterjet, and plasma cutting. Each employs distinct physical principles to sever metal, offering unique trade-offs in precision, speed, thickness capability, and operational expense. While laser excels in thin-to-medium gauge precision, waterjet handles thick, heat-sensitive materials without thermal distortion, and plasma delivers high-speed throughput for medium to heavy sections at lower capital cost.

Understanding Laser Cutting for Steel

How Laser Cutting Works: Precision Through Focused Light

Laser cutting uses a high-powered, focused beam of coherent light—typically generated by CO₂ or fiber lasers—to melt, burn, or vaporize steel along a programmed path. Assist gases such as oxygen or nitrogen are used to eject molten material and enhance cut quality. Modern fiber lasers offer superior beam quality and energy efficiency, enabling faster processing with minimal heat input.

Ideal Steel Thicknesses and Material Compatibility

Laser cutting is most effective on mild steel up to 1 inch thick, with optimal performance between 1/8″ and 1/2″. Stainless steel and aluminum can also be processed, though reflective surfaces may require specialized optics or coatings to prevent back-reflection damage. Thicknesses beyond 1″ become increasingly challenging due to reduced beam penetration and slower speeds.

Cost Per Inch Breakdown: Equipment, Energy, and Labor

Fiber laser systems represent a substantial upfront investment but offer low per-inch costs in high-volume scenarios. Energy consumption ranges from 15–40 kW depending on power and thickness, while labor costs are minimized through automation. Consumables like nozzles and lenses require periodic replacement but are relatively inexpensive compared to other methods.

Advantages: Speed, Accuracy, and Edge Quality

Laser cutting delivers exceptional dimensional accuracy (±0.005″), narrow kerf widths (0.006″–0.012″), and smooth edges that often eliminate secondary finishing. Cutting speeds for 1/4″ mild steel can exceed 200 inches per minute (IPM), making it ideal for intricate parts and tight-tolerance components.

Limitations: Thickness Constraints and Reflective Material Challenges

Beyond 1″ thickness, laser efficiency drops sharply, requiring multiple passes or reduced speeds. Highly reflective materials like polished stainless steel or aluminum can deflect the beam, risking optic damage. Additionally, initial system costs and facility requirements (e.g., ventilation, power stability) may deter small-scale operations.

Waterjet Cutting: High-Pressure Precision for Steel

The Science Behind Waterjet Cutting: Abrasive vs Pure Water

Waterjet cutting employs ultra-high-pressure water (up to 90,000 psi) directed through a small orifice. For steel, an abrasive such as garnet is added to the stream, creating a erosive cutting action capable of slicing through dense metals. Pure waterjets are reserved for softer materials; abrasive waterjets are standard for ferrous alloys.

Performance Across Steel Grades and Thicknesses

Waterjet technology cuts virtually any steel grade—including hardened tool steels and high-strength alloys—with consistent quality from 1/16″ to over 6″ thick. There is no material limitation based on hardness or conductivity, making it uniquely versatile for complex or mixed-material projects.

Cost Per Inch Analysis: Water Consumption, Abrasive Use, and Maintenance

Operational costs are dominated by abrasive consumption (typically $0.50–$1.50 per pound) and water usage (~1 gallon per minute). High-pressure pumps and intensifiers require regular maintenance, contributing to downtime and service expenses. Despite higher per-inch costs than laser or plasma in many cases, waterjet avoids secondary operations due to its clean cuts.

Strengths: No Heat-Affected Zone and Versatility

Because waterjet cutting is a cold process, it produces no heat-affected zone (HAZ), preserving the mechanical properties of the base metal. This makes it ideal for pre-hardened steels, aerospace components, and applications where metallurgical integrity is paramount.

Drawbacks: Slower Speeds and Higher Operational Costs

Cutting speeds are significantly slower than laser or plasma—often under 20 IPM for 1″ steel—resulting in longer cycle times. The abrasive media and pump wear also drive up long-term ownership costs, particularly in continuous production environments.

Plasma Cutting: Speed and Affordability for Industrial Steel

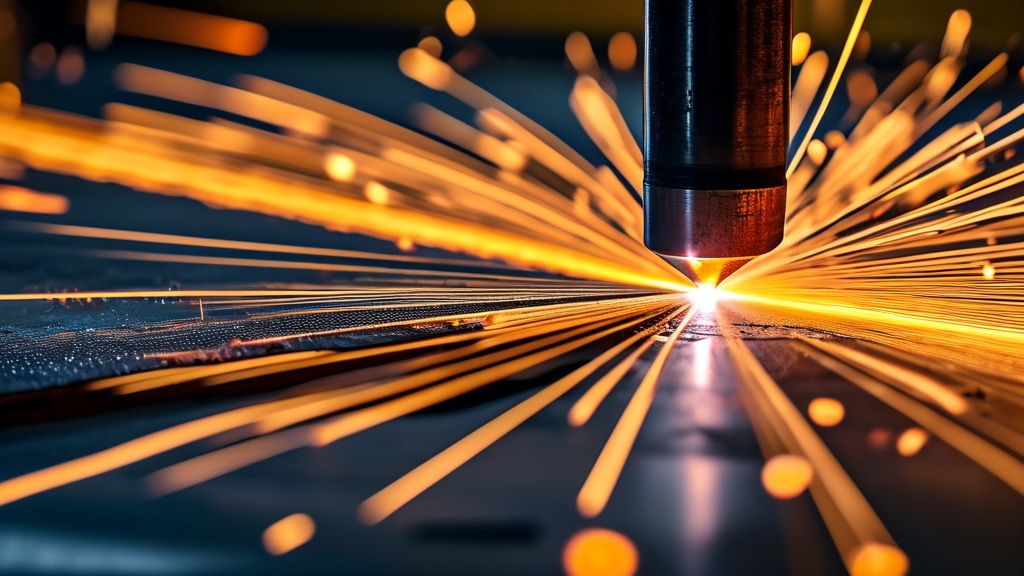

How Plasma Cutting Delivers High-Speed Metal Separation

Plasma cutting ionizes gas (typically air, oxygen, or nitrogen) to form a high-temperature (up to 25,000°F) conductive jet that melts and blows away molten steel. Modern CNC plasma systems use precision torches and advanced arc control to maintain accuracy across varying thicknesses.

Optimal Applications: Medium to Thick Steel Sections

Plasma excels at cutting mild steel from 1/4″ to 2″ thick, with some high-definition systems handling up to 3″. It is widely used in structural fabrication, shipbuilding, and heavy equipment manufacturing where speed and cost outweigh ultra-fine tolerances.

Cost Per Inch Evaluation: Power Usage, Consumables, and Setup

Plasma systems have lower initial costs and consume less energy than lasers or waterjets. However, consumables—including electrodes, nozzles, and shields—require frequent replacement, especially in high-duty cycles. Labor costs remain moderate due to semi-automated operation.

Benefits: Low-Cost Entry and High Throughput

For shops prioritizing volume over micron-level precision, plasma offers unmatched value. Cutting speeds for 1/2″ steel can reach 100 IPM or more, enabling rapid turnaround on large structural components.

Trade-Offs: Heat Distortion and Surface Finish Limitations

The intense heat generates a noticeable HAZ and can cause warping in thin sections. Edge quality is rougher than laser or waterjet, often requiring grinding or machining for mating surfaces. Tolerances typically range from ±0.015″ to ±0.030″, limiting use in precision engineering.

Direct Cost Per Inch Comparison: Laser vs Waterjet vs Plasma

Benchmarking Cutting Speeds by Steel Thickness (1/8″, 1/4″, 1/2″, 1″)

- 1/8″ steel: Laser (~300 IPM), Plasma (~250 IPM), Waterjet (~80 IPM)

- 1/4″ steel: Laser (~200 IPM), Plasma (~180 IPM), Waterjet (~50 IPM)

- 1/2″ steel: Laser (~80 IPM), Plasma (~100 IPM), Waterjet (~25 IPM)

- 1″ steel: Laser (~30 IPM), Plasma (~60 IPM), Waterjet (~15 IPM)

These speeds directly influence labor and machine time costs, with laser dominating thin sections and plasma gaining advantage in thicker materials.

Material Waste and Kerf Width Impact on Effective Cost

Kerf width affects nesting efficiency and material yield. Laser’s narrow kerf (0.008″) allows tighter part spacing, reducing scrap. Plasma kerfs range from 0.040″ to 0.080″, while waterjet kerfs are ~0.045″–0.060″. In high-material-cost projects, this difference can significantly alter total expenditure.

Hidden Costs: Maintenance, Consumables, and Downtime

While plasma has low upfront costs, frequent consumable changes and torch maintenance increase lifecycle expenses. Waterjet’s pump rebuilds every 500–1,000 hours add substantial overhead. Laser systems, though costly initially, benefit from minimal consumables and high uptime in automated setups.

Real-World Cost Ranges: Low, Mid, and High-Volume Production Scenarios

- Low volume: Waterjet may be justified for complex, thick parts despite higher per-inch cost.

- Mid volume: Plasma offers the best balance of speed and affordability for structural work.

- High volume: Fiber laser achieves the lowest total cost per inch due to automation and speed.

Choosing the Right Cutting Method for Your Project

Matching Technology to Steel Type, Thickness, and Tolerance Requirements

Define your project’s critical parameters: required tolerance, material grade, thickness, and surface finish. Use laser for precision components under 1″, waterjet for thick or heat-sensitive alloys, and plasma for economical cutting of structural steel above 1/4″.

When to Prioritize Speed Over Precision (and Vice Versa)

In construction or heavy fabrication, speed and cost often trump micron-level accuracy. Conversely, aerospace, medical, or automotive applications demand the repeatability and clean edges only laser or waterjet can provide.

Total Cost of Ownership vs Upfront Cutting Expense

Evaluate not just the quoted price per inch, but the full lifecycle cost—including setup, secondary operations, scrap rates, and machine availability. A slightly higher per-inch rate may yield lower total cost if it reduces rework or improves yield.

Sustainability and Environmental Considerations

Laser and plasma systems consume significant electricity but produce minimal waste. Waterjet uses abundant water and natural abrasives but generates slurry requiring disposal. Consider facility capabilities and environmental regulations when selecting a method.

Future Trends and Technological Advancements

Innovations in Fiber Laser Efficiency and Cost Reduction

Next-generation fiber lasers offer higher power densities, improved beam control, and reduced energy consumption. As prices continue to fall, laser cutting is becoming viable for thicker applications previously dominated by plasma.

Hybrid Systems: Combining Plasma and Laser for Optimal Performance

Emerging hybrid machines integrate plasma for rough cutting and laser for finishing, maximizing speed and precision. These systems are particularly effective in shipbuilding and large-scale structural fabrication.

Automation and AI in Reducing Per-Inch Cutting Costs

AI-driven nesting software, predictive maintenance, and robotic loading/unloading are minimizing non-cut time and optimizing material usage. These advancements are driving down effective cost per inch across all technologies.

Conclusion: Making an Informed Decision on Steel Cutting Services

Summary of Cost-Per-Inch Insights Across Technologies

Laser cutting delivers the lowest cost per inch for thin-to-medium steel in high-volume settings, waterjet provides unmatched versatility for thick or sensitive materials at a premium, and plasma remains the most economical choice for heavy structural work where precision is secondary.

Final Recommendations Based on Project Scope and Budget

Assess your project’s technical and financial constraints holistically. For tight-tolerance, high-mix production, lean toward laser. For thick-section, heat-sensitive steel, choose waterjet. For cost-driven, high-throughput structural jobs, plasma is hard to beat.

Partnering with the Right Fabrication Provider for Maximum Value

Work with a fabrication partner like Baoli Iron & Steel that offers multiple cutting technologies under one roof. This ensures unbiased recommendations, optimized process selection, and seamless integration with welding, forming, and finishing—delivering maximum value from quote to delivery.