Description

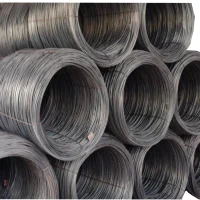

Premium Galvanized Carbon Steel Wires: Durability Meets Performance

At Baoli Iron Steel, we specialize in manufacturing high-quality Galvanized Carbon Steel Wires, engineered to deliver exceptional performance and extended service life in demanding environments. Our wires undergo a meticulous zinc coating process, creating a robust barrier against corrosion and rust, making them an indispensable material for a myriad of industrial, agricultural, and construction applications globally.

Understanding the Galvanization Process: The Shield of Zinc

Galvanization is the cornerstone of our wires’ superior protective qualities. This process involves applying a protective zinc coating to the carbon steel wire, primarily through two methods:

- Hot-Dip Galvanization: This widely adopted method involves immersing the cleaned carbon steel wire into a bath of molten zinc. The high temperature ensures a metallurgical bond between the zinc and the steel, forming a multi-layered coating that includes zinc-iron alloy layers and an outer layer of pure zinc. This results in a thick, highly durable coating offering sacrificial and barrier protection against corrosion, even if scratched.

- Electro-Galvanization: An electrolytic process where zinc ions are deposited onto the steel wire from an aqueous solution. This method typically produces a thinner, more uniform, and aesthetically pleasing coating. While offering good corrosion resistance, it is generally less robust than hot-dip galvanization for outdoor, heavy-duty applications.

The zinc coating acts as a sacrificial anode, corroding preferentially to protect the underlying steel, ensuring the wire maintains its structural integrity and aesthetic appeal over time.

The Core: High-Quality Carbon Steel Base Material

Our galvanized wires are drawn from carefully selected, high-grade carbon steel, primarily utilizing:

- Low Carbon Steel (e.g., Q195, SAE1006, SAE1008): Chosen for its excellent ductility and workability, allowing for easy drawing into various wire gauges without compromising strength. This ensures flexibility for applications like binding, fencing, and weaving.

This foundational strength, combined with the protective zinc layer, creates a wire that is both robust and versatile.

Key Features & Performance Advantages

- Superior Corrosion & Rust Resistance: Significantly extends wire lifespan, especially in harsh outdoor conditions.

- High Tensile Strength: Offers excellent load-bearing capabilities and resistance to breakage.

- Excellent Ductility & Flexibility: Easy to bend, tie, and manipulate without fracturing, facilitating diverse applications.

- Abrasion Resistance: The tough zinc coating provides added resistance against wear and tear.

- Aesthetic Appeal: The bright, silvery finish is suitable for visible applications.

- Cost-Effectiveness: Long service life reduces replacement frequency and associated costs.

Technical Specifications & Common Dimensions

Our Galvanized Carbon Steel Wires are manufactured to stringent international standards (e.g., ASTM A641, GB/T 3081). We offer a wide range of specifications to meet diverse project requirements:

| Specification | Typical Range/Details | Notes |

|---|---|---|

| Material Grade | Q195, SAE1006, SAE1008 (Low Carbon Steel) | Ensures optimal ductility for wire drawing. |

| Wire Diameter | 0.5 mm – 6.0 mm (approx. 24 SWG to 2 SWG) | Available in BWG, SWG, AWG, or metric gauges. |

| Zinc Coating Weight | 30 g/m² – 250 g/m² (or higher upon request) | Varies based on galvanization method & application needs. |

| Tensile Strength | 350 N/mm² – 550 N/mm² (50,000 – 80,000 PSI) | Customizable based on specific requirements (e.g., soft, medium, hard temper). |

| Elongation | ≥ 10% – 25% (depending on temper) | Indicates the wire’s ductility before breaking. |

| Packing Options | Small Coils, Big Coils, Spools, U-type Wire, Straightened & Cut Wire | Weight per coil/spool can be customized (e.g., 0.5kg to 1000kg). |

Note: Specific dimensions, coating thicknesses, and mechanical properties can be customized.

Diverse Applications

The versatility and durability of our galvanized carbon steel wires make them ideal for a broad spectrum of uses:

- Fencing & Security: Chain link fence, barbed wire, razor wire, field fence, gabion mesh, security barriers.

- Construction: Rebar tying wire, binding wire, mesh fabrication, concrete reinforcement.

- Agriculture: Baling wire, vineyard wire, trellising, livestock enclosures.

- Industrial: Cable armouring, wire mesh, hangers, arts & crafts, general binding.

- Daily Use: Clotheslines, garden ties, various DIY projects.

Why Partner with Baoli Iron Steel? Your Trusted Supplier

As a leading Chinese manufacturer, Baoli Iron Steel is committed to delivering excellence in steel materials. We understand the critical role quality plays in your projects, and our galvanized wires are produced under strict quality control measures to ensure consistent performance and reliability.

Our Commitment & Services:

- Global Export Reach: We proudly export our high-quality galvanized carbon steel wires to numerous countries and regions worldwide, ensuring efficient and reliable delivery to your doorstep.

- Extensive Customization Options: We offer a wide range of specifications, including various gauges, lengths, zinc coating weights, tensile strengths, and packing types, tailored to meet your unique project demands.

- Assured Quality & Certification: All our products adhere to international standards, backed by comprehensive testing and quality assurance processes.

- Competitive Pricing: As a direct factory, we offer competitive pricing without compromising on quality.

- Dedicated Customer Support: Our team is ready to provide technical assistance and personalized service to ensure your complete satisfaction.

Contact Baoli Iron Steel today to discuss your galvanized carbon steel wire requirements. We look forward to being your reliable partner.