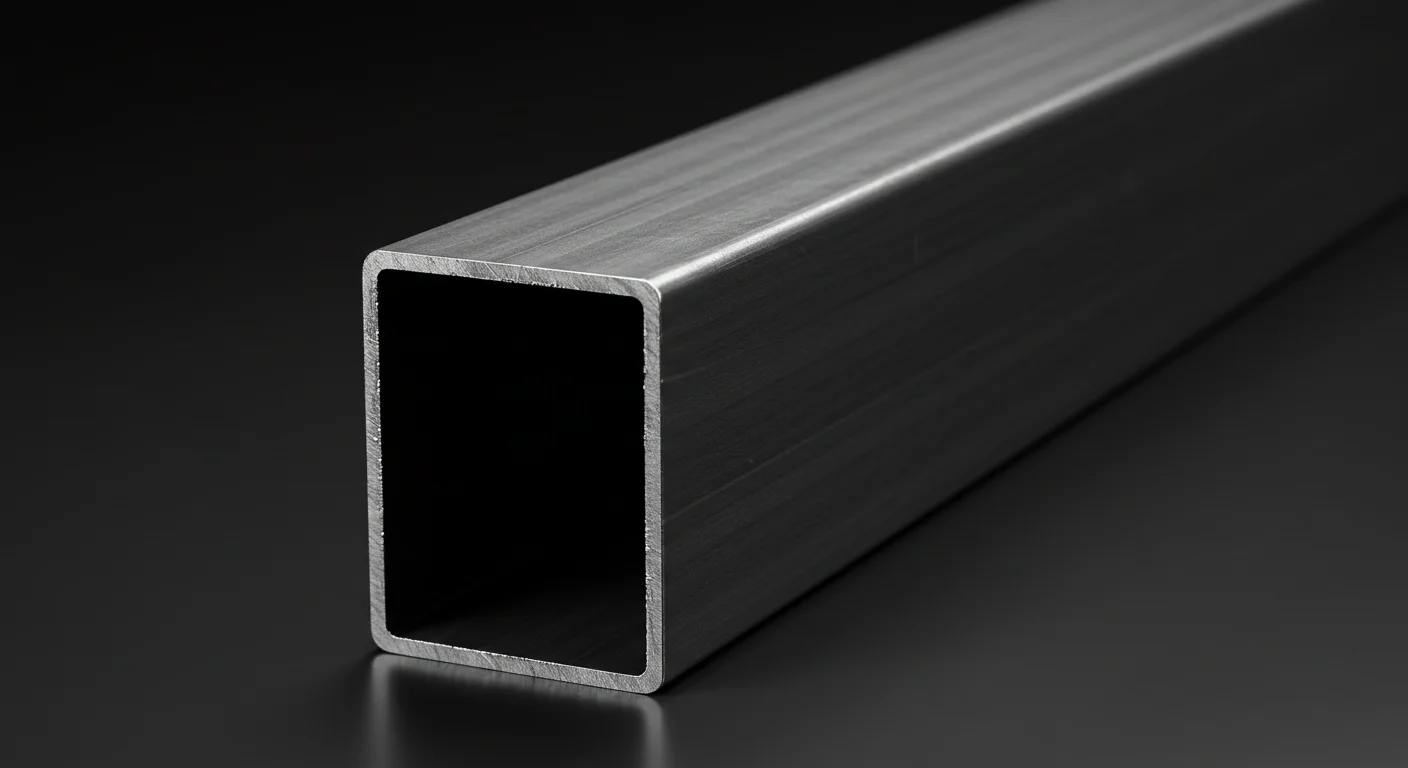

## Decoding the Stainless Steel Rectangular Tube Weight Chart: A Practical Guide

The stainless steel rectangular tube weight chart is a crucial tool for engineers, fabricators, and anyone working with this versatile material. Understanding how to interpret and utilize this chart is paramount for accurate material estimations, cost calculations, and efficient project planning. This article will delve into the intricacies of these charts, explaining their structure, the factors influencing weight, and best practices for application.

**Understanding the Chart’s Structure:**

A typical stainless steel rectangular tube weight chart presents data in a tabular format. The key parameters usually included are:

* **Outside Dimensions:** These are the width and height (or depth) of the rectangular tube’s outer dimensions, typically expressed in millimeters (mm) or inches (in).

* **Wall Thickness:** This specifies the thickness of the tube’s walls, again in mm or in. This is a critical factor influencing weight.

* **Length:** While not always explicitly tabulated (as weight is usually expressed per unit length), the length is implicitly understood. Weight calculations are generally based on a standard length (e.g., one meter).

* **Weight per Unit Length:** This is the most important piece of information – it represents the weight of a one-meter (or one-foot) length of the specified rectangular tube. This is usually expressed in kilograms per meter (kg/m) or pounds per foot (lb/ft).

* **Grade of Stainless Steel:** The chart might specify different grades of stainless steel (e.g., 304, 316, 430), each possessing slightly different densities, hence influencing the weight.

**Factors Affecting Weight:**

Several factors beyond the dimensions directly contribute to the weight of a stainless steel rectangular tube:

* **Grade of Stainless Steel:** Different stainless steel grades have different densities. Austenitic grades (like 304 and 316) generally have higher densities than ferritic grades (like 430).

* **Manufacturing Tolerances:** Slight variations in dimensions during manufacturing can lead to minor differences in the actual weight compared to the chart’s values.

* **Surface Finish:** While generally negligible, significant surface treatments might slightly alter the weight.

**Using the Weight Chart Effectively:**

To use the chart efficiently, follow these steps:

1. **Identify your required dimensions:** Determine the necessary outside dimensions (width and height) and wall thickness of the rectangular tube.

2. **Locate the appropriate entry:** Find the corresponding entry in the chart matching these dimensions and the grade of stainless steel.

3. **Obtain the weight per unit length:** This value will be listed in the chart.

4. **Calculate the total weight:** Multiply the weight per unit length by the total required length of the tube to determine the total weight. Remember to account for any additional material needed for cuts, welds, or waste.

**Beyond the Chart:**

While weight charts are invaluable, it’s crucial to remember they provide *approximate* values. For high-precision applications, it is advisable to confirm the weight with the supplier, especially when dealing with large quantities of material. Furthermore, consult relevant material datasheets for precise density information related to the specific grade and manufacturing process.

In conclusion, the stainless steel rectangular tube weight chart is an essential tool for efficient material management and cost estimation. Understanding its structure, the influencing factors, and proper application will lead to more accurate calculations and improved project outcomes. Remember to always double-check with the supplier for critical applications or large orders to account for potential variations.

Stainless Steel Rectangular Tube Weight Chart: A Complete Guide — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.

Leave a Reply