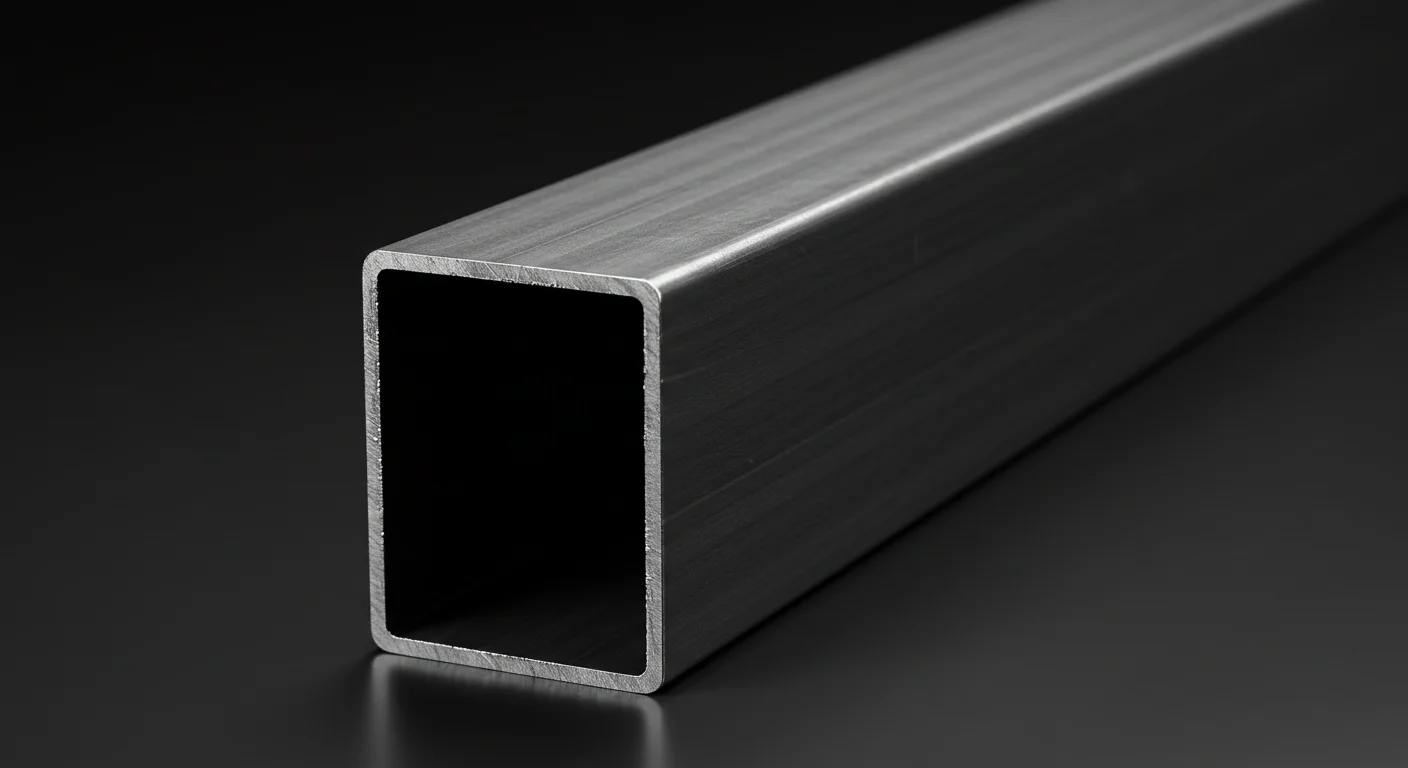

Calculating the weight of a rectangular steel tube is a common requirement in engineering, construction, and fabrication projects. Knowing the precise weight is crucial for structural analysis, transportation planning, cost estimation, and material handling. The calculation itself is based on fundamental principles of geometry and material properties.

The Basic Principle: Volume x Density

The weight of any object can be determined by multiplying its volume by the density of the material it’s made from. For a steel tube, we need to find the volume of the steel *itself*, not the total volume enclosed by the outer dimensions. This means calculating the volume of the walls of the tube.

Steps to Calculate the Weight

- Determine the Dimensions: You need the following measurements for the rectangular tube:

- Outer Width (W)

- Outer Height (H)

- Wall Thickness (t)

- Length of the Tube (L)

It’s crucial that all these dimensions are in consistent units (e.g., all in millimeters, meters, inches, or feet) before starting the calculation.

- Calculate the Cross-Sectional Area of the Steel: This is the area of the outer rectangle minus the area of the inner hollow rectangle.

- Outer Area (A_outer) = W * H

- Inner Width (W_inner) = W – 2t

- Inner Height (H_inner) = H – 2t

- Inner Area (A_inner) = W_inner * H_inner = (W – 2t) * (H – 2t)

- Cross-Sectional Area of Steel (A_steel) = A_outer – A_inner = (W * H) – [(W – 2t) * (H – 2t)]

Ensure ‘t’ is the thickness of a single wall.

- Calculate the Volume of the Steel: Multiply the cross-sectional area of the steel by the length of the tube.

Volume (V) = A_steel * L

Volume (V) = [(W * H) – (W – 2t) * (H – 2t)] * L - Identify the Density of Steel: The density (ρ) of steel varies slightly depending on the grade and composition. A common value used for carbon steel is approximately:

- 7850 kilograms per cubic meter (kg/m³)

- 0.283 pounds per cubic inch (lb/in³)

- 490 pounds per cubic foot (lb/ft³)

Always try to use the specific density for the type of steel you are using if accuracy is critical. Stainless steels might have slightly different densities (e.g., around 7950-8000 kg/m³).

- Calculate the Weight: Multiply the volume of the steel by its density. Make sure your units are compatible!

Weight = Volume * Density

Weight = {[(W * H) – (W – 2t) * (H – 2t)] * L} * ρIf your dimensions (W, H, t, L) were in millimeters (mm) and you use density in kg/m³, you’ll need to convert the volume from cubic millimeters (mm³) to cubic meters (m³) before multiplying. (1 m³ = 1,000,000,000 mm³). Alternatively, convert density to kg/mm³. A common approach is to convert all initial dimensions to meters first.

Example Calculation

Let’s calculate the weight of a rectangular steel tube with:

- Outer Width (W) = 100 mm = 0.1 m

- Outer Height (H) = 50 mm = 0.05 m

- Wall Thickness (t) = 3 mm = 0.003 m

- Length (L) = 2 meters

- Density (ρ) = 7850 kg/m³

- A_steel = (0.1 * 0.05) – [(0.1 – 2*0.003) * (0.05 – 2*0.003)]

- A_steel = 0.005 – [(0.1 – 0.006) * (0.05 – 0.006)]

- A_steel = 0.005 – [0.094 * 0.044]

- A_steel = 0.005 – 0.004136 = 0.000864 m²

- Volume (V) = A_steel * L = 0.000864 m² * 2 m = 0.001728 m³

- Weight = V * ρ = 0.001728 m³ * 7850 kg/m³ ≈ 13.56 kg

Therefore, a 2-meter long rectangular steel tube with these dimensions weighs approximately 13.56 kilograms. Understanding this process allows for accurate estimation for various sizes and lengths of steel tubes.

Key Specifications

- Standards and grades

- Dimensions and tolerances

- Surface finish

- Certificates (MTC)

Applications

Construction, machinery, energy and general fabrication — match material and finish to the operating environment.