The question How much does a steel tube weigh? is broad because the weight depends entirely on several factors: the tube’s dimensions (shape and size), its length, and the specific type (grade) of steel used.

Key Factors Determining Steel Tube Weight

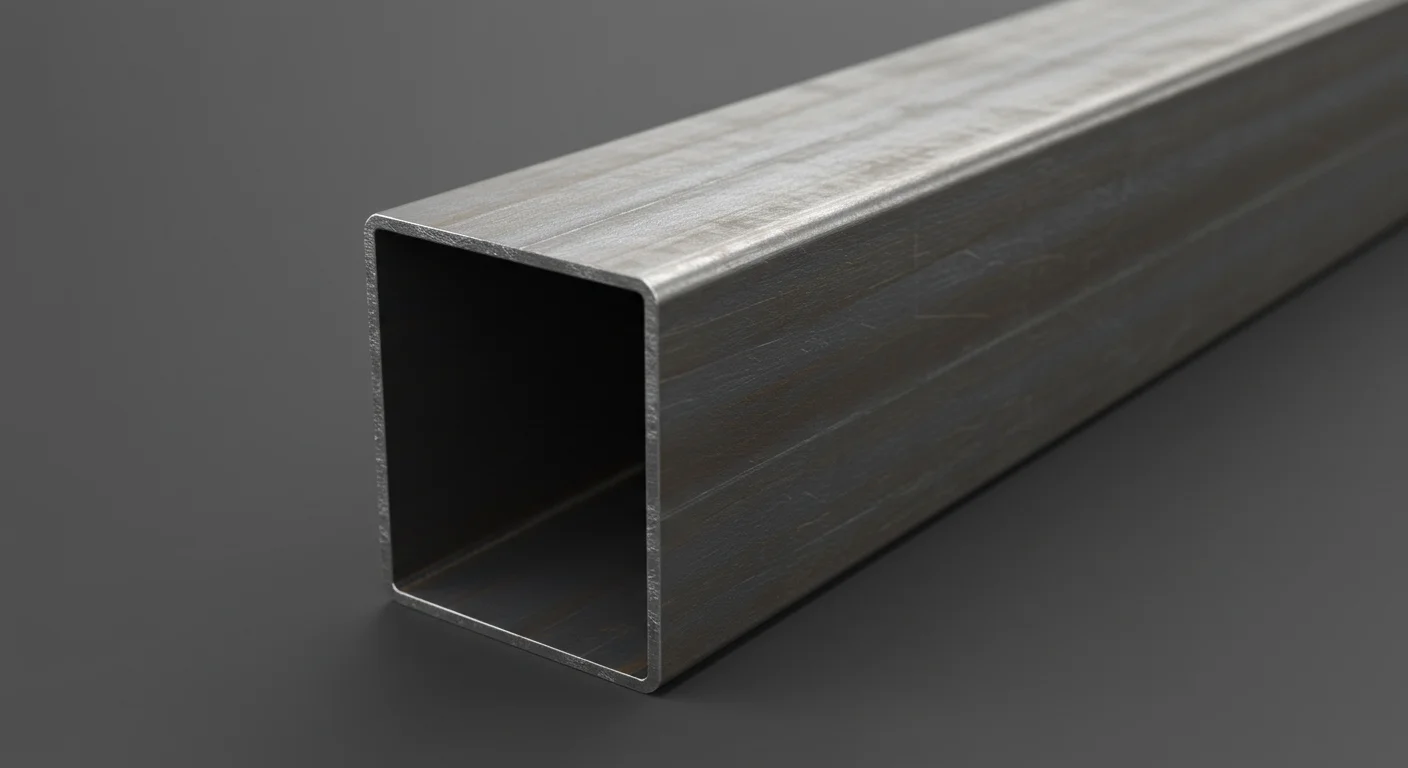

- Dimensions & Shape: Is it a round, square, or rectangular tube? What are its outer dimensions (diameter for round, width/height for rectangular/square)? Crucially, what is the wall thickness? A thicker wall means more material and thus more weight.

- Length: A longer tube will naturally weigh more than a shorter tube of the same cross-section. Weight is often quoted ‘per meter’ or ‘per foot’.

- Steel Density: Different steel alloys have slightly different densities. While common carbon steel is around 7850 kg/m³ (0.283 lb/in³), stainless steel or other alloys can vary. Precision requires knowing the density of the specific steel grade.

The Universal Calculation Method

Regardless of the specific type of steel tube, the fundamental way to calculate its weight remains the same:

Weight = Volume of Steel × Density of Steel

The challenge lies in calculating the Volume of Steel accurately.

Calculating the Volume of Steel

You need to find the volume of the material that makes up the tube walls. This is done by:

- Calculating the Cross-Sectional Area of the Steel: This is the total area occupied by the steel in a slice perpendicular to the tube’s length.

- For Round Tubes: Area = π/4 * (Outer Diameter² – Inner Diameter²). Note: Inner Diameter = Outer Diameter – 2 * Wall Thickness.

- For Square Tubes: Area = Outer Side² – Inner Side². Note: Inner Side = Outer Side – 2 * Wall Thickness.

- For Rectangular Tubes: Area = (Outer Width * Outer Height) – (Inner Width * Inner Height). Note: Inner dimensions are Outer dimensions minus 2 * Wall Thickness.

- Calculating the Total Volume: Multiply the Cross-Sectional Area of Steel by the Length of the tube.

Volume = Cross-Sectional Area × Length

Consistency is Key: Ensure all your measurements (dimensions, length) are in the same unit system (e.g., all meters, or all millimeters, or all inches) before calculating the volume. Then, use the density value corresponding to those units (e.g., kg/m³, g/mm³, lb/in³).

Finding the Necessary Information

To answer How much does a steel tube weigh? accurately, you need to specify:

- The shape (round, square, rectangular).

- The outer dimensions (e.g., 50mm diameter, 4×4 inches, 100×50 mm).

- The wall thickness (e.g., 3mm, 0.125 inches).

- The length (e.g., 1 meter, 6 feet, 20 feet).

- Optionally, the specific steel grade (e.g., A36 carbon steel, 304 stainless steel) to use the precise density. If unknown, a standard density like 7850 kg/m³ is often used for estimation.

Without these details, one can only provide general formulas or examples for specific, common sizes. Always refer to supplier documentation or measure the actual tube for precise weight calculation when needed for engineering or logistical purposes.

Key Specifications

- Standards and grades

- Dimensions and tolerances

- Surface finish

- Certificates (MTC)

Applications

Construction, machinery, energy and general fabrication — match material and finish to the operating environment.