Calculating the weight of tubing, whether it’s round, square, rectangular, or another profile, follows a consistent methodology based on its geometry and material properties. The core principle relies on determining the volume of the material making up the tube and multiplying it by the material’s density.

The Fundamental Formula

The universal formula to calculate the weight of tubing is:

Step-by-Step Calculation Process

-

Identify Necessary Dimensions: You need the precise geometrical measurements of the tube’s cross-section and its overall length.

- For Round Tubing: Outer Diameter (OD) and Wall Thickness (t), OR Outer Diameter (OD) and Inner Diameter (ID). Remember ID = OD – 2t.

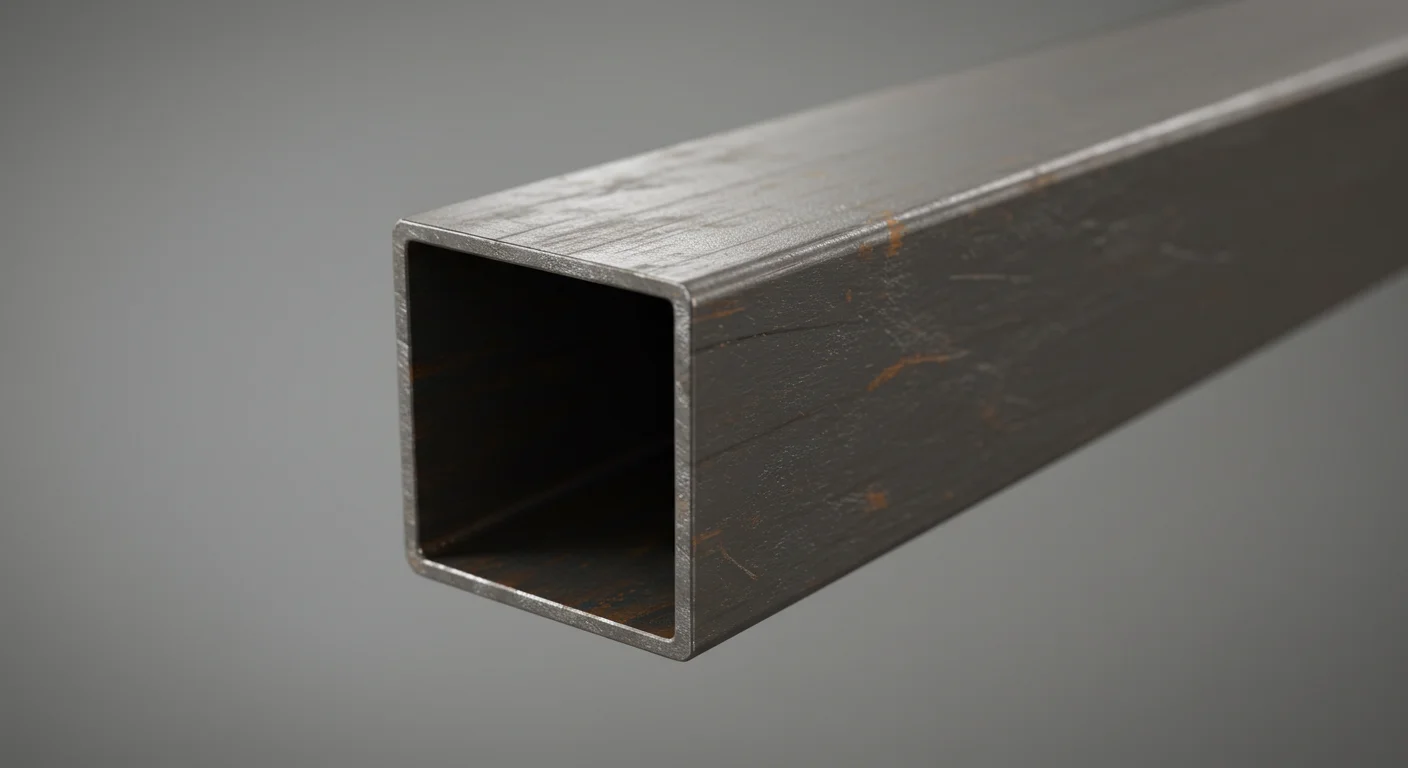

- For Square Tubing: Outer Side Length (S) and Wall Thickness (t).

- For Rectangular Tubing: Outer Width (W), Outer Height (H), and Wall Thickness (t).

- Overall Length (L): The total length of the tubing section.

Crucially, ensure all measurements are converted to a consistent unit system (e.g., everything in millimeters, meters, inches, or feet) before proceeding.

-

Calculate the Cross-Sectional Area of the Material (A_material): This is the area of the material if you were to slice the tube perpendicularly. It’s calculated by subtracting the area of the inner void from the area of the outer shape.

- Round Tubing: A_material = (π/4) * (OD² – ID²) = (π/4) * [OD² – (OD – 2t)²]

- Square Tubing: A_material = S² – (S – 2t)²

- Rectangular Tubing: A_material = (W * H) – [(W – 2t) * (H – 2t)]

-

Calculate the Volume of the Material (V): Multiply the cross-sectional area of the material by the length of the tube.

Volume (V) = A_material × L

-

Determine the Density (ρ) of the Material: Find the density of the specific material the tubing is made from (e.g., carbon steel, stainless steel, aluminum, copper). Density is mass per unit volume. Common values include:

- Steel: ~7850 kg/m³ or ~0.283 lb/in³

- Aluminum: ~2700 kg/m³ or ~0.098 lb/in³

- Stainless Steel (e.g., 304): ~7900-8000 kg/m³ or ~0.285-0.289 lb/in³

Use the density value that corresponds to the unit system you used for volume calculation (e.g., kg/m³ if volume is in m³, lb/in³ if volume is in in³).

-

Calculate the Final Weight: Multiply the calculated volume by the material’s density.

Weight = V × ρ

By following these steps carefully and ensuring dimensional and unit accuracy, you can reliably calculate the weight of any type of tubing. This process is essential for various applications, including structural engineering, material procurement, shipping logistics, and project cost estimation. Remember to consider the specific material (steel density, aluminum density, etc.) for the most accurate weight calculations.

Key Specifications

- Standards and grades

- Dimensions and tolerances

- Surface finish

- Certificates (MTC)

Applications

Construction, machinery, energy and general fabrication — match material and finish to the operating environment.