Understanding 304L Stainless Steel

304L stainless steel signifies a specific grade within the austenitic stainless steel family, one of the most widely used types globally. The “304” indicates its base composition, primarily chromium (around 18%) and nickel (around 8%). These elements are key to its excellent corrosion resistance and formability. The crucial part is the “L”, which stands for “Low Carbon”. Standard 304 stainless steel has a maximum carbon content of 0.08%, whereas 304L stainless steel has a maximum carbon content restricted to just 0.03%.

This reduction in carbon content is highly significant, particularly for applications involving welding. When standard 304 stainless steel is welded or subjected to high temperatures (between 800掳F and 1500掳F or 425掳C and 815掳C), chromium carbides can precipitate at the grain boundaries. This process, known as sensitization, depletes chromium near the grain boundaries, reducing the corrosion resistance in those areas, making the material susceptible to intergranular corrosion, especially in corrosive environments.

By significantly lowering the carbon content, 304L stainless steel minimizes or prevents carbide precipitation during welding and stress relieving operations. This makes 304L the preferred choice for applications requiring extensive welding where post-weld annealing (heat treatment to redissolve carbides) is not feasible or practical. It maintains its corrosion resistance in the as-welded condition, ensuring the integrity of the structure or component.

Key Characteristics of 304L:

- Enhanced Weldability: Reduced risk of sensitization and intergranular corrosion after welding compared to standard 304.

- Excellent Corrosion Resistance: Good resistance to atmospheric corrosion, many organic and inorganic chemicals, and food and beverage environments. Similar to standard 304 in most environments, except where welding is involved.

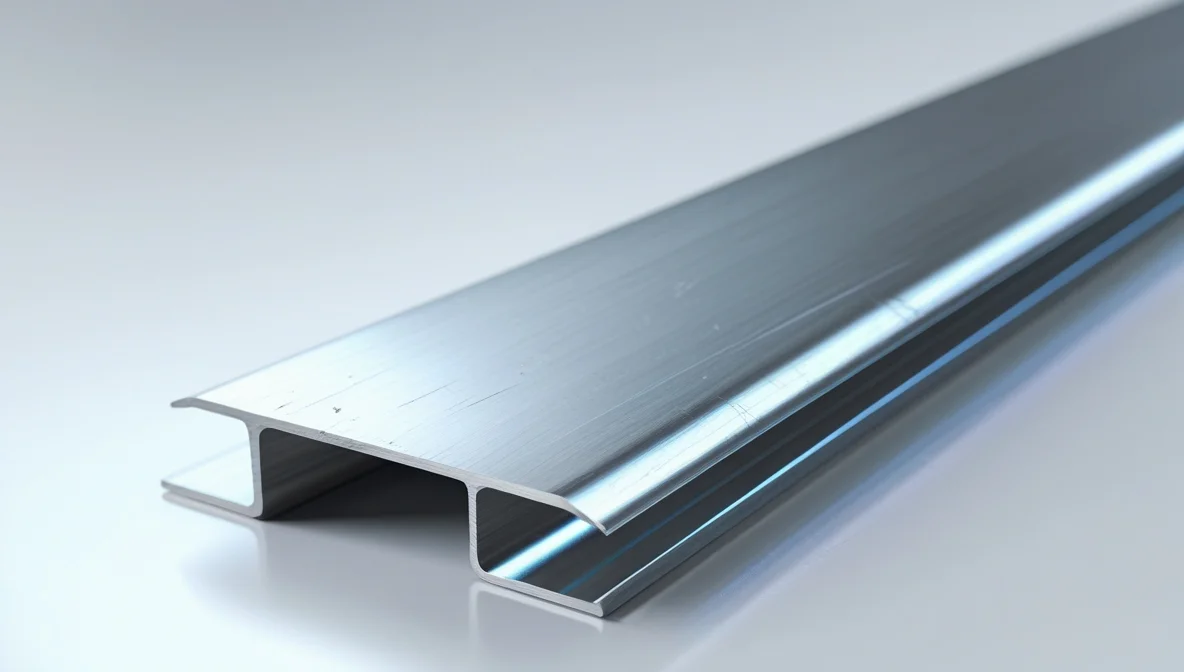

- Good Formability and Drawability: Like standard 304, it can be easily formed, drawn, and stamped.

- Non-magnetic: Typically non-magnetic in the annealed condition, but can become slightly magnetic after cold working.

- Slightly Lower Strength: Due to the lower carbon content, 304L has slightly lower yield and tensile strength compared to standard 304, though this difference is often negligible for many applications.

In summary, 304L means a low-carbon variant of the popular 304 stainless steel, specifically designed to improve weldability and prevent sensitization, thereby maintaining corrosion resistance in welded structures without needing post-weld heat treatment. Its combination of properties makes it a versatile material for chemical processing equipment, food processing, dairy equipment, brewing hardware, cryogenic vessels, and architectural applications where welding is prevalent.

Key Specifications

- Standards and grades

- Dimensions and tolerances

- Surface finish

- Certificates (MTC)

Applications

Construction, machinery, energy and general fabrication — match material and finish to the operating environment.