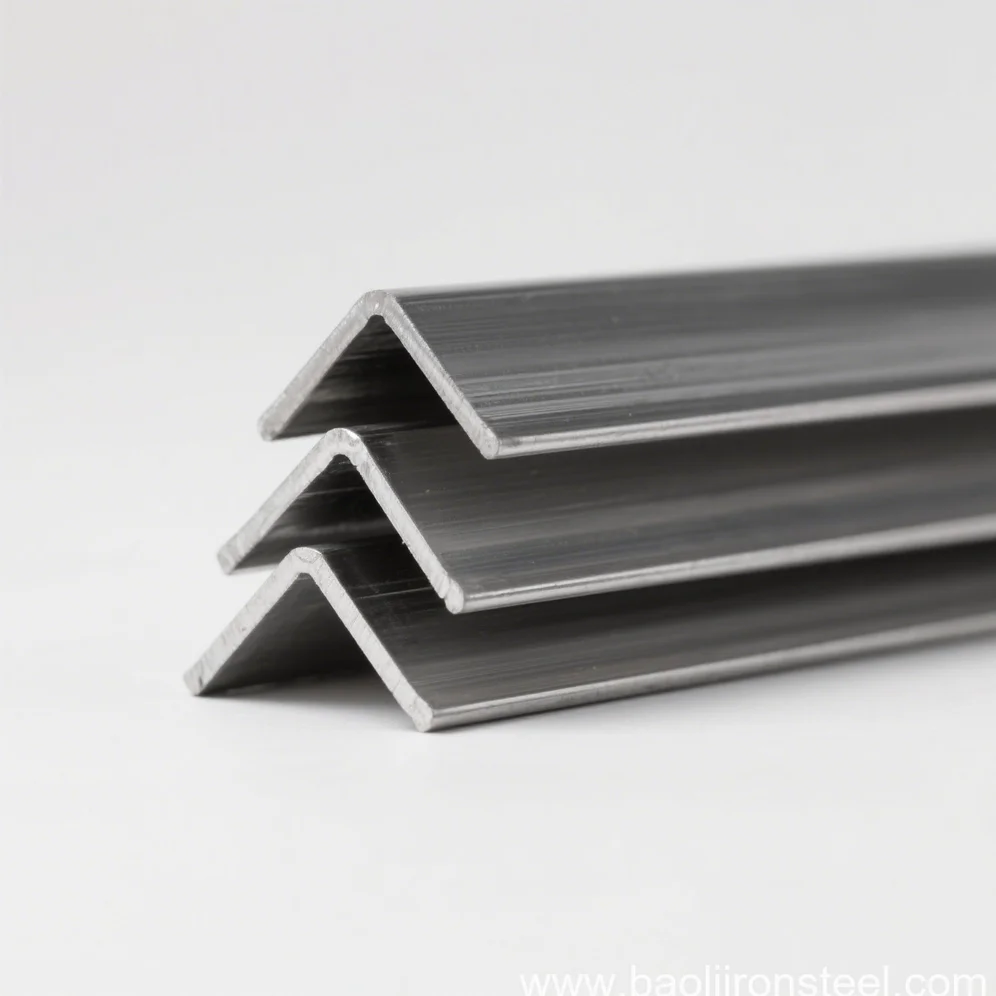

In the intricate world of construction, manufacturing, and various industrial applications, the choice of materials plays a pivotal role in a project’s success. Among the myriad of essential components, stainless steel angle bars stand out for their exceptional strength, corrosion resistance, and versatility. While standard sizes are readily available, opting for custom-sized stainless steel angle bars offers a multitude of benefits that can significantly optimize your project’s efficiency, cost-effectiveness, and overall quality. This article delves into the compelling advantages of investing in tailor-made stainless steel angle bars, illustrating how they can be a game-changer for your specific requirements.

Unmatched Precision and Perfect Fit

One of the most immediate and impactful benefits of custom size stainless steel angle bars is the unparalleled precision they offer. When you order angles cut to your exact specifications, you eliminate the need for on-site cutting, grinding, or welding to adjust standard sizes. This precision ensures a perfect fit, which is crucial for structural integrity, aesthetic appeal, and seamless assembly. For complex designs or tight tolerances, generic sizes often lead to compromises or extensive rework, both of which can compromise the final product or structure. Customization means your components arrive ready for installation, perfectly aligning with your blueprints, ensuring superior quality in every detail.

Significant Cost Efficiencies

While the initial per-unit cost of a custom component might seem higher than a standard one, the long-term cost savings are substantial and contribute significantly to your project’s budget.

Reduced Material Waste

When using standard bars for unique applications, it’s common to cut off excess material, leading to scrap. Custom orders ensure you only pay for and receive the material you need, dramatically reducing waste and associated disposal costs. This approach not only aligns with sustainable practices, minimizing environmental impact, but also directly boosts your project’s bottom line by optimizing material utilization.

Lower Labor Costs

On-site fabrication, including cutting, bending, and finishing standard angle bars, requires skilled labor and significant time investments. By receiving pre-cut, custom-sized pieces, your on-site team can concentrate on assembly rather than preparation, thereby freeing up valuable human resources and considerably accelerating project timelines. This efficiency directly translates into savings on labor.

Minimized Equipment Usage

Eliminating the need for extensive on-site cutting and shaping means less wear and tear on your specialized equipment, which in turn reduces maintenance costs. Furthermore, it helps prevent potential downtime that could arise from machinery breakdowns, ensuring a smoother operation.

Enhanced Performance and Durability

Customization extends beyond mere dimensions; it encompasses the ability to specify material grades and finishes that are precisely optimized for your application’s unique environmental and load-bearing requirements. For instance, in highly corrosive environments, a specific grade of stainless steel (e.g., 316L) with a particular surface finish might be absolutely essential to ensure longevity. Ordering custom ensures your angle bars possess the exact properties needed to withstand specific stresses, extreme temperatures, or chemical exposures, thereby significantly enhancing the long-term durability and consistent performance of your structure or product. This proactive approach prevents premature failure, ultimately reducing costly repairs or replacements in the future and safeguarding your investment.

Design Flexibility and Aesthetic Integration

Architects and engineers often face creative limitations when constrained by only standard material sizes. Custom-sized stainless steel angle bars liberate design possibilities, allowing for the creation of more intricate, unique, and functionally superior structures. Whether your project demands a specific leg length, a particular thickness, or a precise angle that deviates from the standard 90 degrees, customization opens up a world of innovative opportunities. This flexibility is particularly vital in modern architectural and industrial design, where sophisticated aesthetics and structural innovation are often inseparable. A perfectly sized angle bar contributes not only to the overall structural integrity but also to the clean lines, precise alignment, and polished appearance of the final product.

Accelerated Project Timelines

Time is often the most critical and valuable resource in any project. By receiving pre-fabricated, custom stainless steel angle bars that are ready for immediate use, the assembly and installation process can commence directly upon delivery. This significantly reduces overall lead times compared to the multi-step process of sourcing standard sizes and then undertaking subsequent in-house fabrication. A streamlined workflow translates directly into projects that can be completed faster, leading to earlier revenue generation, quicker market entry, or accelerated operational readiness. This kind of agility is especially beneficial for fast-paced industries or projects operating under stringent deadlines.

Reduced On-Site Hazards and Improved Safety

On-site cutting, grinding, and welding of steel components can inherently be hazardous operations, involving risks such as sparks, loud noises, and potential for injury due to material handling. By outsourcing these precise fabrication processes to a specialized manufacturer, you drastically minimize the need for such potentially dangerous activities on your immediate job site. This proactive approach directly translates to a safer working environment for your team, a reduction in potential accidents, and subsequently, diminished liability. The ready-to-install nature of custom angle bars ensures a cleaner, quieter, and ultimately more organized and secure work area.

Consistent Quality and Reliable Supply Chain

When you partner with a reputable steel manufacturer like BaoLi Iron & Steel Co.,Ltd, you gain immediate access to a highly controlled and optimized production environment. Our stringent quality control system ensures that every single custom-sized stainless steel angle bar produced meets your exact specifications and adheres to the highest international industry standards. This rigorous process eliminates potential variations and inconsistencies that can often arise from less controlled, ad-hoc on-site fabrication. As a leading Chinese steel manufacturer, BaoLi Iron & Steel is deeply committed to “100% customer satisfaction” through robust quality assurance protocols and the maintenance of a reliable global supply chain. This commitment ensures your custom materials are delivered precisely on time and exactly as specified, giving you peace of mind throughout your project lifecycle.

Tailored for Diverse Applications

Custom stainless steel angle bars demonstrate remarkable versatility, finding essential applications across a vast spectrum of industries. From providing robust supporting structures in highly demanding chemical processing plants (where superior corrosion resistance is paramount), to serving as elegant architectural elements in modern buildings (where precise aesthetics are key), or acting as critical components in the automotive industry (demanding micro-level precise tolerances) – the ability to customize makes them uniquely adaptable. This inherent versatility ensures that regardless of your project’s specific and unique demands, a perfectly tailored solution is always possible, delivering optimal performance whether it involves specific load-bearing requirements, extreme corrosive environments, or challenging thermal conditions.

Choosing Your Custom Steel Partner

Selecting the right supplier for your custom stainless steel angle bars is a decision of paramount importance that can significantly impact your project’s outcome. A truly reliable partner, such as BaoLi Iron & Steel Co.,Ltd, will possess not just the manufacturing capabilities, but also the core expertise to deliver comprehensive solutions, not merely products. Our proven expertise lies in consistently offering custom steel solutions that precisely match intricate client needs. This is strongly backed by an experienced professional team dedicated to providing essential technical guidance for optimal steel selection and application. We meticulously manage the entire logistical process, from precision production and rigorous quality control to global transportation and complex contract management, thereby ensuring a completely seamless and worry-free experience for our clients. Our deeply ingrained client-centric philosophy means we are wholly focused on ensuring your project’s success through continuous innovation and unparalleled professional service.

In conclusion, while standard stainless steel angle bars serve many general purposes effectively, the benefits of opting for custom sizes are compelling, multifaceted, and far-reaching. From achieving unparalleled precision and realizing significant long-term cost savings to ensuring enhanced performance, fostering greater design freedom, and accelerating project timelines, custom solutions offer a decisive strategic advantage. By proactively partnering with a dedicated, capable, and client-focused manufacturer, you can confidently ensure that your project benefits from components that are perfectly engineered for optimal success and longevity.