When sourcing structural materials for construction, industrial fabrication, or engineering projects, stainless steel channel bars are a top choice due to their strength, corrosion resistance, and long-term durability. However, not all channel bars are created equal. Ensuring quality and proper certification is critical to the success and safety of your application. This guide will walk you through the key factors to consider when buying stainless steel channel bar, including material grades, dimensional accuracy, surface finish, mechanical properties, and required certifications.

As a global supplier, BaoLi Iron & Steel Co., Ltd adheres to international quality standards and delivers premium-grade stainless steel channel bars tailored to project-specific needs. With decades of expertise in metallurgy and manufacturing, we emphasize traceability, testing, and compliance across every batch.

Material Grade and Composition Verification

The first and most crucial step in evaluating a stainless steel channel bar is confirming the correct alloy grade. Common grades include 304/L, 316/L, and 430, each offering different levels of corrosion resistance, strength, and temperature tolerance. For marine environments or chemical processing plants, 316/L is preferred due to its molybdenum content, enhancing pitting resistance.

Reputable suppliers provide Mill Test Certificates (MTCs) according to EN 10204 Type 3.1 or 3.2, which validate chemical composition via spectrographic analysis. Always request these documents and cross-check values against ASTM/ASME or ISO standards.

Dimensional Tolerances and Structural Integrity

Precision in dimensions ensures seamless integration into frameworks and load-bearing assemblies. National standards such as ASTM A484 (USA), EN 10088-3 (Europe), and GB/T 4227 (China) define allowable tolerances for height, flange width, web thickness, and leg length.

| Nominal Size (mm) | Height Tolerance | Web Thickness Tolerance | Flange Width Tolerance |

|---|---|---|---|

| 100 × 50 × 5 | ±1.0 mm | ±0.5 mm | ±0.8 mm |

| 150 × 75 × 6 | ±1.2 mm | ±0.6 mm | ±1.0 mm |

| 200 × 80 × 8 | ±1.5 mm | ±0.8 mm | ±1.2 mm |

Manufacturers like BaoLi Iron & Steel utilize precision rolling techniques and laser measurement systems to maintain consistency within tight tolerances. Custom sizes outside standard catalogs are also available upon request.

Mechanical Properties and Performance Testing

A high-quality stainless steel channel bar must meet minimum mechanical property benchmarks. Key parameters include:

- Tensile Strength: Typically 520–700 MPa for 304/316 grades

- Yield Strength: Minimum 205–310 MPa depending on grade and condition

- Elongation: At least 40% in 50 mm to ensure formability

- Hardness: Usually below 95 HRB for standard annealed material

Independent third-party testing reports or in-house certified lab results should be available upon request. These include tensile tests, impact tests (Charpy V-notch), and intergranular corrosion testing (e.g., ASTM A262).

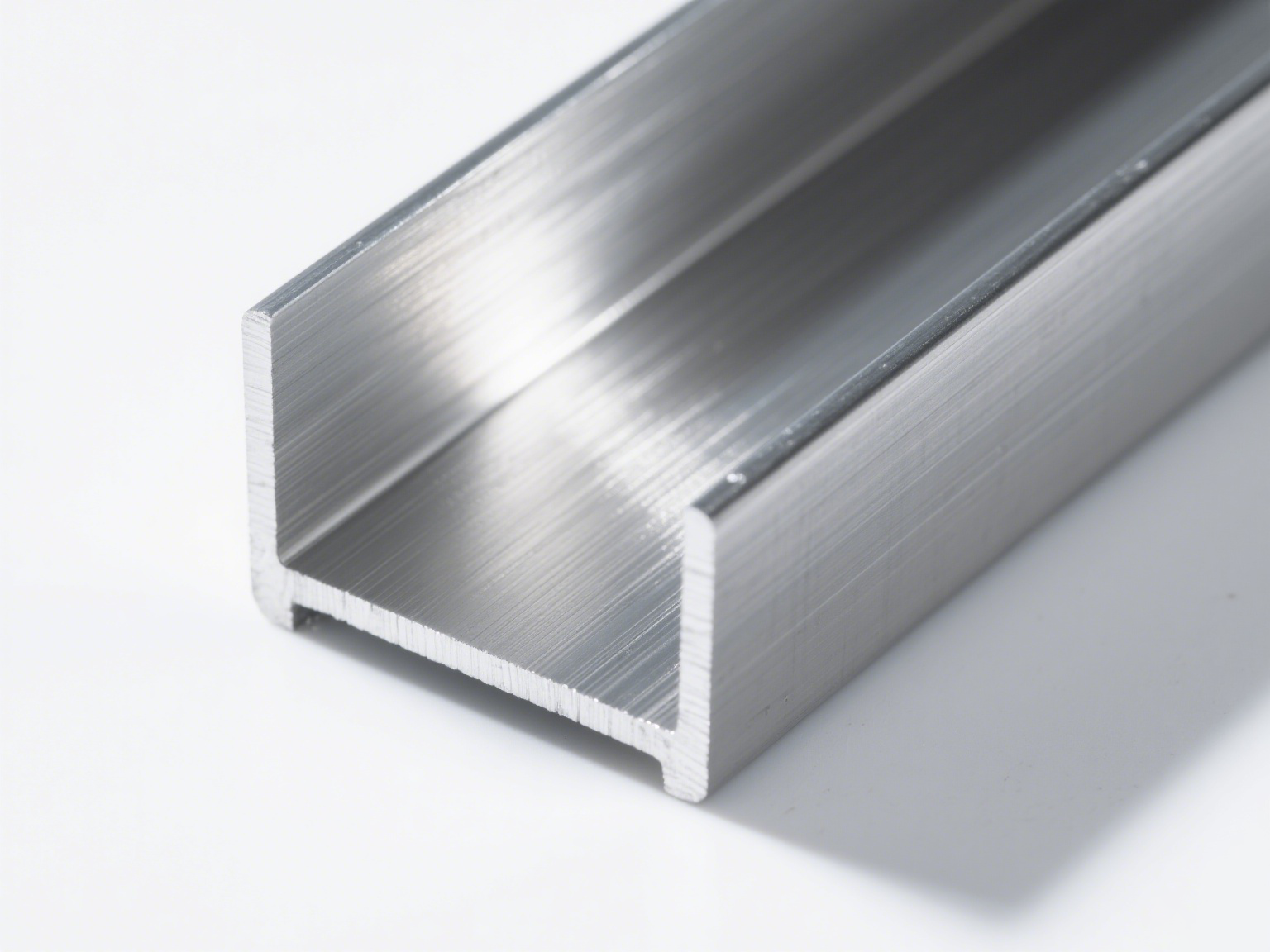

Surface Quality and Finishes

Surface imperfections like scale, cracks, seams, or deep scratches compromise both aesthetics and structural integrity. Standard finishes include:

- No.1 Finish: Hot-rolled, annealed, and pickled – common for industrial use

- 2B Finish: Cold-rolled with higher smoothness – ideal for moderate corrosion resistance

- BA (Bright Annealed): Reflective finish used in architectural applications

At BaoLi Iron & Steel, channels undergo rigorous visual and non-destructive testing (NDT), including eddy current and ultrasonic inspection, to guarantee flawless surfaces.

Certifications and Traceability

Look for suppliers certified under ISO 9001:2015, ISO 14001, and OHSAS 18001. Additional project-specific approvals may include:

- API Monogram (for oil & gas sectors)

- PED/CE Marking (for EU pressure equipment)

- LR, DNV, BV Class approvals (marine applications)

Each batch from BaoLi Iron & Steel’s stainless steel channel bar line includes heat number traceability, ensuring full lifecycle accountability from raw material to final delivery.

In summary, buying a reliable stainless steel channel bar demands attention to material chemistry, dimensional precision, mechanical performance, surface quality, and documentation. Partnering with a supplier committed to quality, like BaoLi Iron & Steel, ensures your structural needs are met with consistency, safety, and compliance.

Contact us today to request technical data sheets, samples, or customized quotes.