-

How Much Extra Does Steel Cost Per Ton for Urgent 7-Day Delivery Compared to Standard Lead Time?

Understanding the Cost Premium for Urgent 7-Day Steel Delivery Defining Standard vs. Urgent Lead Times in Steel Procurement In the steel industry, lead times are a critical determinant of both cost and project feasibility. Standard…

-

Seaside Resort Construction: How to Prevent Steel Corrosion from Salt Air Exposure

Seaside Resort Construction: How to Prevent Steel Corrosion from Salt Air Exposure Understanding the Threat: Why Salt Air Accelerates Steel Corrosion Salt air presents one of the most aggressive environments for structural steel, particularly in…

-

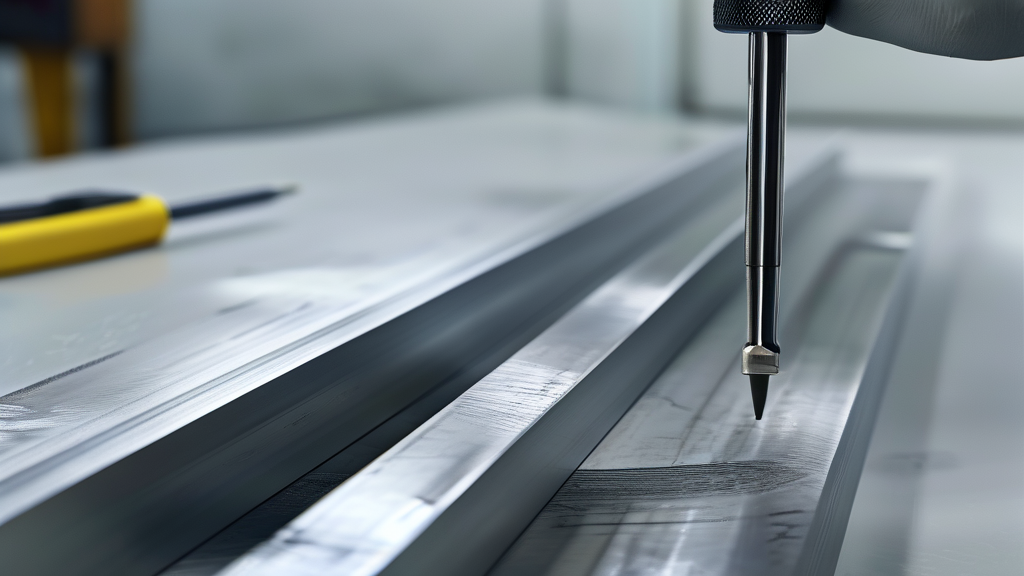

How to Read Steel Mill Test Certificate (MTC): Common Mistakes Buyers Make

How to Read Steel Mill Test Certificate (MTC): Common Mistakes Buyers Make Introduction: Why the MTC Matters More Than You Think A Mill Test Certificate (MTC) is far more than a piece of paperwork—it’s a…

-

Import Steel from China to USA: What Duties, Tariffs, and Documentation Required in 2026?

Overview of U.S. Steel Import Regulations in 2026 As of 2026, importing steel from China to the United States remains a complex and highly regulated process shaped by ongoing geopolitical tensions, evolving supply chain strategies,…

-

Steel Quality Inspection Before Shipping: What Tests Should Third Party Inspector Do?

Introduction: The Critical Role of Third-Party Inspections in Steel Supply Chains In global steel procurement, the margin for error is razor-thin. A single batch of non-compliant or substandard steel can compromise structural integrity, trigger catastrophic…

-

Received Wrong or Damaged Steel Shipment: Step-by-Step Claim Process

Understanding Your Rights When a Steel Shipment Is Incorrect or Damaged Legal and Contractual Protections for Buyers When you purchase steel products—whether structural beams, rebar, or specialty alloys—you enter into a legally binding agreement that…

-

Food Truck Construction: What Stainless Steel Grade for Health Department Approval?

Why Stainless Steel Is Non-Negotiable in Food Truck Builds The Role of Material Safety in Mobile Food Service In the high-mobility, high-turnover environment of a food truck, every surface that contacts food must meet stringent…

-

Steel Price Forecast 2026: When Is the Best Time to Buy Stainless and Carbon Steel?

Introduction: Navigating the Volatile Steel Market in 2026 Why Steel Prices Matter for Buyers and Investors Steel remains the backbone of global industrial activity, underpinning sectors from construction and automotive to energy and infrastructure. For…

-

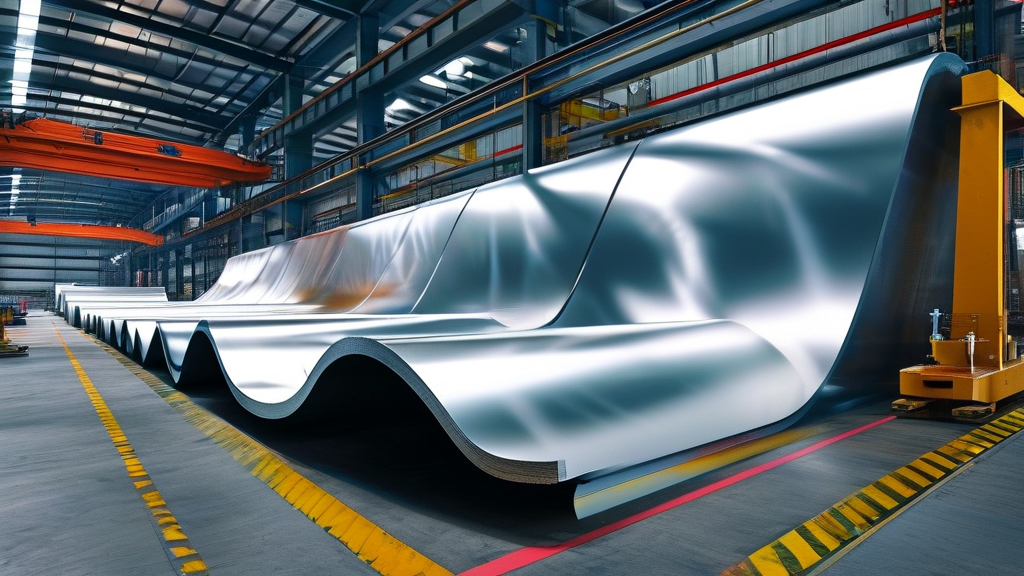

How to Pack Steel Coils for Ocean Shipping to Prevent Rust and Damage During Transport

How to Pack Steel Coils for Ocean Shipping to Prevent Rust and Damage During Transport Understanding the Risks of Ocean Transport for Steel Coils Ocean shipping presents a uniquely challenging environment for steel coils due…

-

Solar Panel Mounting System: Stainless Steel vs Galvanized Steel Cost Comparison for 25-Year Lifespan

Introduction: The Critical Role of Mounting Systems in Solar Longevity Why Material Choice Impacts Total Cost of Ownership The mounting system is the silent backbone of any solar installation—often overlooked during initial planning but fundamentally…