Steel Blog

-

Cut‑to‑Size and Nesting Tips to Reduce Total Cost and Lead Time

How to brief cut-to-size work: process/kerf, lead-ins and tabs, grain and common-line cutting, realistic tolerances, batching, and packing/labels that speed …

-

Corrugated Roofing Sheets: Thickness, Span and Fasteners Guide

A practical guide to corrugated roof design: thickness vs span, coating choice, lap/seal details, fastener placement and a ready-to-use order spec.

-

2B vs BA vs No.4: Stainless Steel Finishes with Real Ra Values

2B vs BA vs No.4: Stainless Steel Finishes with Real Ra Values A buyerfocused, engineeringaware guide with specs, tolerances and selection tips to reduce cos…

-

How to Read a Mill Test Certificate (MTC) and Avoid Costly Mistakes

How to Read a Mill Test Certificate (MTC) and Avoid Costly Mistakes — A buyer‑focused, engineering‑aware guide with specs, tolerances and selection tips to reduce cost and avoid rework. Get instant quote.

-

Polished Stainless Tubing: 180/240/320 Grit and Ra Targets

How to buy polished stainless tube: grit vs Ra ranges, OD/ID finish choices, weld seam blending, electropolish for sanitary, and a ready-to-copy spec.

-

How Long Does Custom Steel Take to Make?

Discover the timeline for custom steel fabrication, from design to delivery. Learn key factors affecting production speed and how to optimize your order for efficiency.

-

Stainless or Galvanized Near the Coast? A Practical Selection Guide

Stainless or Galvanized Near the Coast? A Practical Selection Guide — A buyer‑focused, engineering‑aware guide with specs, tolerances and selection tips to reduce cost and avoid rework. Get instant quote.

-

Steel for Automotive: What You Need

Discover essential insights on automotive steel types, properties, and applications to optimize vehicle performance, safety, and manufacturing efficiency. Stay ahead in the industry.

-

10 Common Ordering Mistakes That Delay Delivery—and How to Avoid Them

A buyer-focused checklist that prevents the 10 order mistakes most likely to push your metal delivery off schedule—complete with copy-paste PO wording.

-

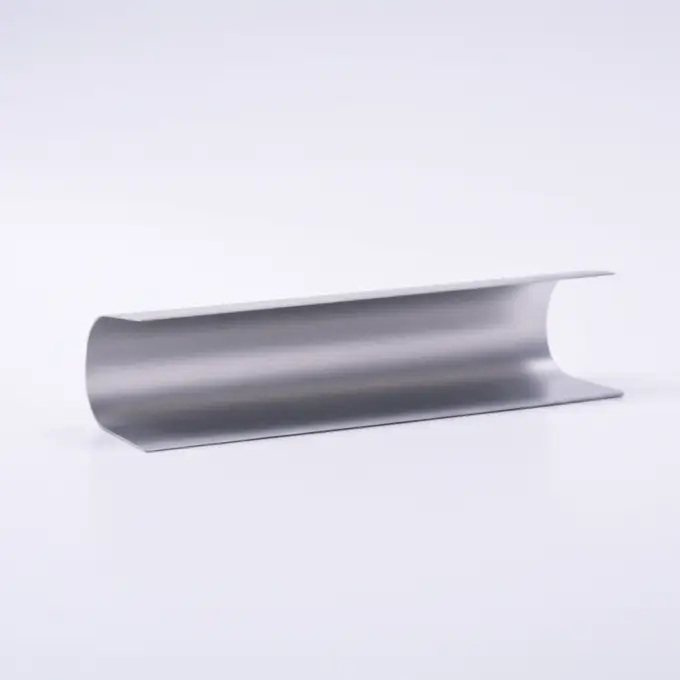

3 Benefits of Custom Steel Profiles

Discover how custom steel profiles enhance strength, reduce waste, and streamline production for industrial applications. Optimize your projects with tailored solutions.