Steel Blog

-

Advantages of Stainless Steel Bright Tubes

Discover the key benefits of stainless steel bright tubes, including superior corrosion resistance, high strength, and polished finishes ideal for precision engineering and industrial applications.

-

Which Steel Is Best for Construction?

Discover the best steel types for construction, comparing strength, durability, cost, and applications to make informed building material choices.

-

Galvanized Steel for Agricultural Use

Discover the benefits of galvanized steel in agriculture—durable, corrosion-resistant, and cost-effective for fencing, irrigation, and storage solutions. Enhance farm efficiency with long-lasting steel.

-

Key Tips to Maintain Carbon Steel

Discover essential tips to maintain carbon steel, prevent rust, and extend its lifespan in industrial applications. Proper care ensures durability and performance.

-

Uses of Stainless Steel Rods

Discover the versatile applications of stainless steel rods in construction, automotive, and manufacturing industries, highlighting their strength, corrosion resistance, and durability.

-

Stainless Steel Bright Tubes: Uses & Tips

Discover the versatile uses of stainless steel bright tubes in industrial applications and expert tips for selection, maintenance, and performance optimization. Enhance durability and efficiency.

-

What Is Carbon Steel Used For?

Discover the versatile applications of carbon steel in construction, automotive, machinery, and more. Learn why its strength, durability, and cost-efficiency make it a top choice across industries.

-

Custom Stainless Steel: Easy to Get?

Discover how custom stainless steel solutions are more accessible than ever, with expert insights on sourcing, fabrication, and cost-effective options for industrial needs.

-

Carbon Steel for Shipping Containers: Standards and Custom Fabrication

The global shipping industry relies heavily on the durability, strength, and cost-effectiveness of carbon steel for container fabrication. As the backbone of international trade, shipping containers must withstand extreme environmental conditions, mechanical stresses, and long-term…

-

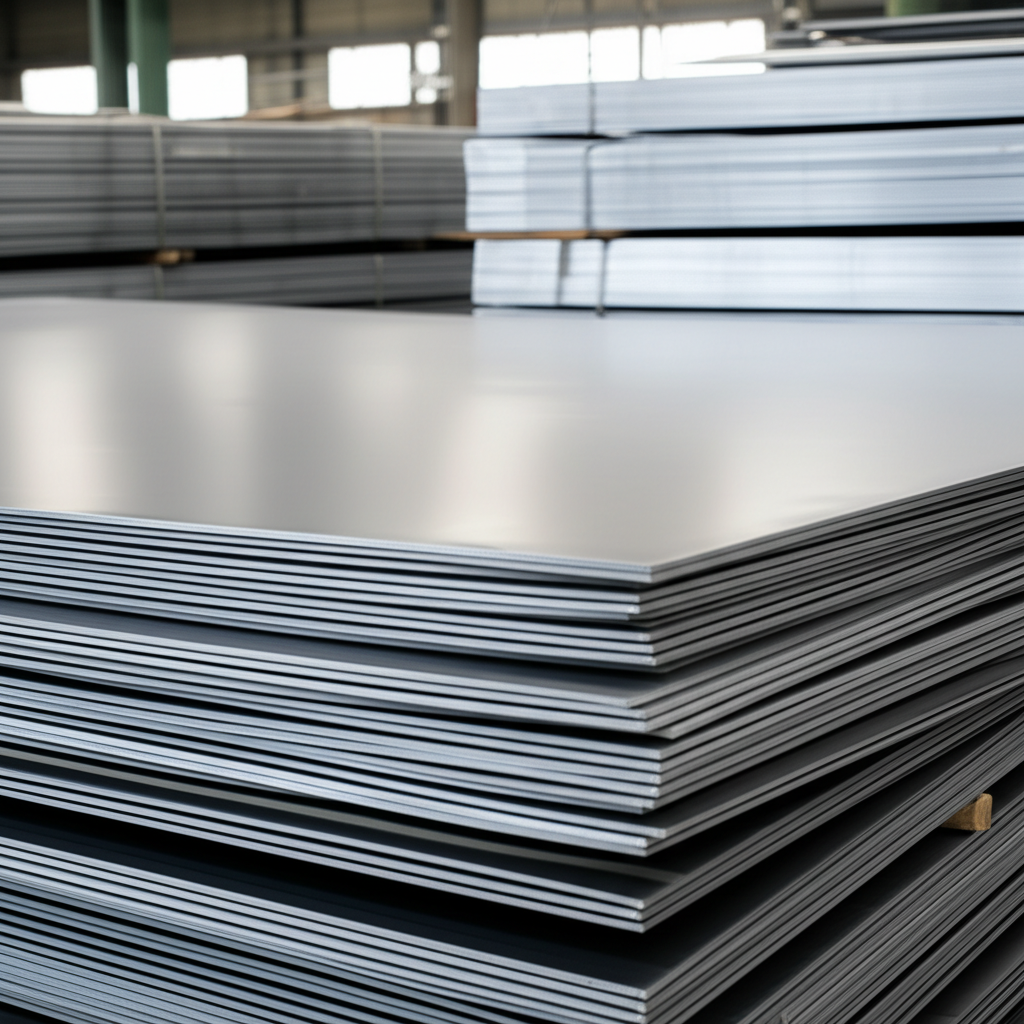

Sourcing Carbon Steel Plates for Construction: A Buyer’s Guide

When sourcing carbon steel plates for construction projects, buyers must balance technical specifications, cost-efficiency, and long-term performance. This guide provides a comprehensive framework to navigate the selection process while addressing critical factors from material properties…