Steel Blog

-

Stainless Steel Coils for Large-Scale Infrastructure Projects

When it comes to large-scale infrastructure projects, the choice of materials is critical to ensuring durability, cost-effectiveness, and long-term performance. Among the most versatile and reliable materials available today, stainless steel coils stand out as…

-

Precision Steel Slitting: Technical Parameters and Industrial Applications

Steel slitting is a critical process in metal fabrication that involves cutting large coils of steel into narrower, more manageable strips while maintaining precise dimensions and edge quality. This technique is widely employed in industries…

-

Exporting 304 Stainless Steel Plates: A Guide to Specs, Logistics, and CE Certification

When it comes to exporting 304 stainless steel plates, understanding the technical specifications, logistics requirements, and certification standards is critical for ensuring seamless international trade. This guide breaks down the essential elements for manufacturers, importers,…

-

Stainless Steel Selection: Food-Grade vs. Industrial-Grade

When selecting stainless steel for specific applications, the choice between food-grade and industrial-grade variants is critical. While both types share the core properties of corrosion resistance and durability, their differences in composition, performance, and regulatory…

-

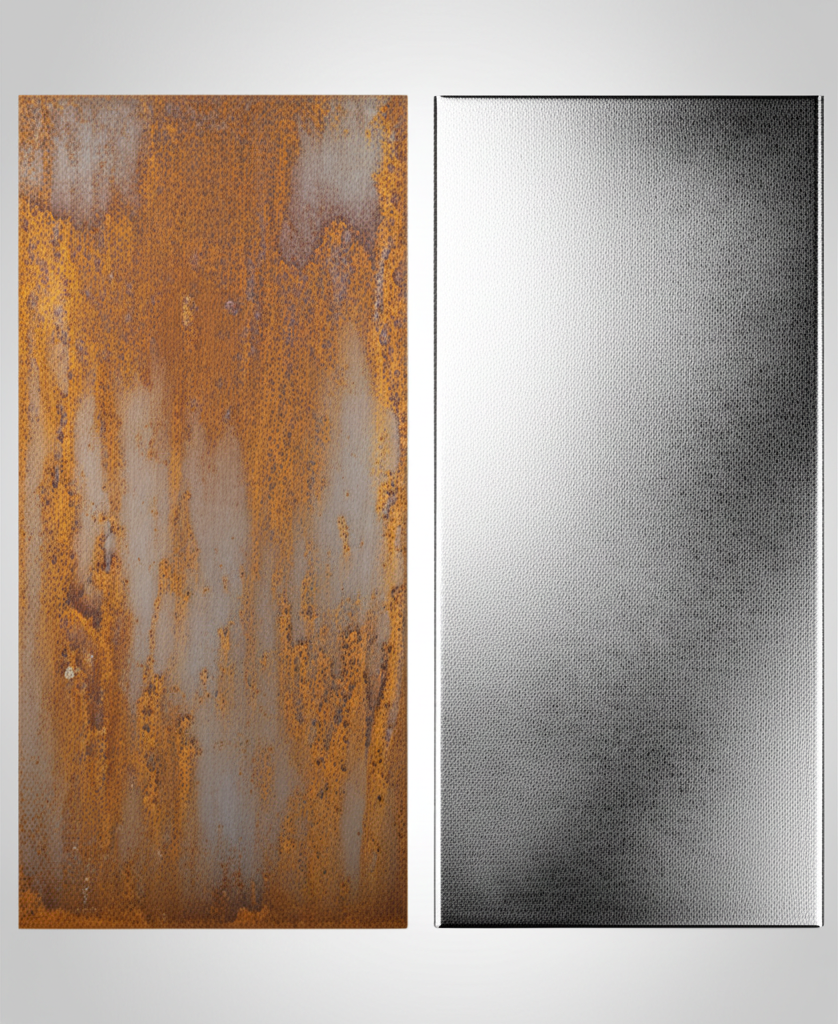

Carbon Steel vs. Galvanized Steel: A Performance and Corrosion Comparison

When selecting steel for construction, manufacturing, or infrastructure projects, the debate between carbon steel and galvanized steel often arises. Both materials have distinct properties, advantages, and limitations, particularly in terms of performance and corrosion resistance.…

-

Exporting Galvanized Steel Pipes to the Middle East: A Market Guide

The Middle East represents one of the most dynamic markets for galvanized steel pipes, driven by rapid infrastructure development, urbanization, and industrial expansion. Exporting galvanized steel pipes to this region requires a strategic understanding of…

-

Sourcing Galvanized Steel for Automotive Lightweighting

The automotive industry is undergoing a transformative shift toward lightweighting, driven by stringent emissions regulations, fuel efficiency demands, and the rise of electric vehicles (EVs). Among the materials enabling this transition, galvanized steel has emerged…

-

2025 Galvanized Steel Pipe Market Outlook: Rising Demand for High-Zinc Coatings and Custom Sizing

The galvanized steel pipe market is entering 2025 with robust momentum, underpinned by resilient construction activity, infrastructure modernization, municipal water upgrades, and a steady recovery in light manufacturing. A defining trend is the accelerated shift…

-

ASTM A123 vs. ISO 1461: Comparing Global Standards for Hot-Dip Galvanized Coatings on Steel Pipes

Hot-dip galvanizing remains one of the most reliable and cost-effective methods to protect steel pipes against atmospheric, splash, soil, and industrial corrosive environments. Two globally recognized specifications—ASTM A123 and ISO 1461—define the performance and inspection…

-

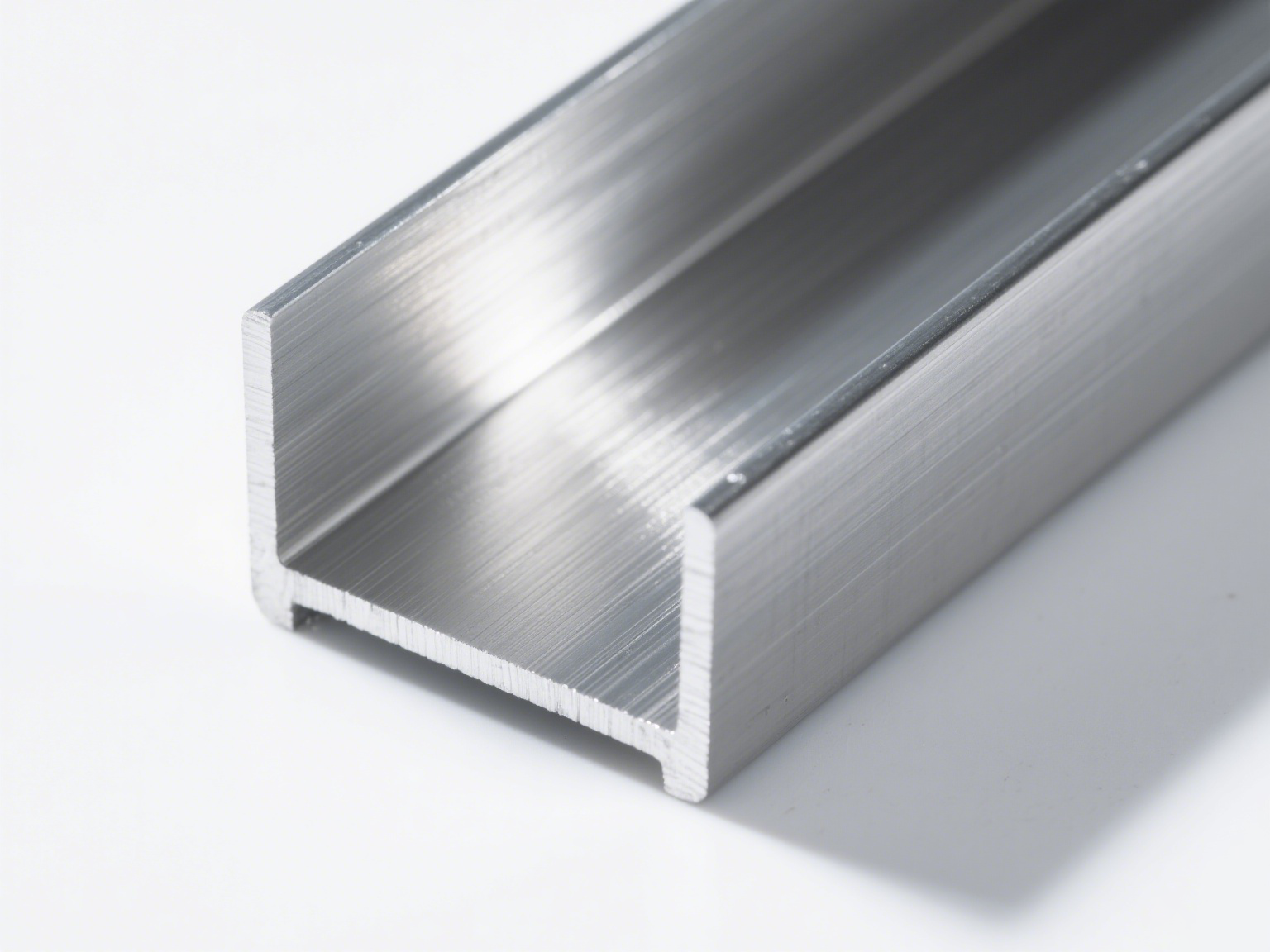

Lightweight vs Heavy-Duty Stainless Steel Channel Bar: Choosing Based on Project Needs

When designing structural frameworks, architectural facades, or industrial support systems, selecting the right material is critical to long-term durability, cost-efficiency, and performance. Among the most widely used structural profiles in modern engineering applications is the…