Introduction to Cold-Rolled Full Hard Coil: Defining a High-Strength Steel Product

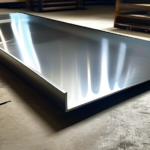

What Is Cold-Rolled Full Hard Coil?

Cold-rolled full hard coil refers to a type of steel product produced through a cold-reduction process that significantly increases its yield and tensile strength by reducing the thickness of hot-rolled steel without subsequent annealing. This process results in a material with minimal ductility but exceptional strength, making it ideal for structural and industrial applications. The term “full hard” indicates that the steel has undergone maximum cold work without intermediate annealing, achieving a hardness level typically above 85 HRB (Rockwell B scale). For a deeper understanding of the broader cold-rolling process, see Cold rolling on Wikipedia.

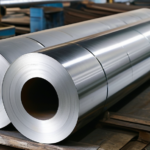

Key Production Process: From Hot-Rolled Coil to Full Hard

The journey begins with a hot-rolled coil, which is pickled to remove scale and then cold-reduced by 50–85% in thickness using tandem rolling mills. This high degree of deformation introduces strain hardening, locking dislocations in the crystal structure and increasing strength. Unlike other cold-rolled steels, full hard coils skip the annealing step, preserving the work-hardened state. This makes them unsuitable for deep drawing but excellent for applications requiring high stiffness and load-bearing capacity.

Mechanical Properties: Strength and Formability Trade-Offs

Tensile and Yield Strength Advantages

Cold-rolled full hard coils exhibit significantly higher tensile and yield strength compared to annealed or hot-rolled steels. Typical yield strengths range from 400 to 600 MPa, with tensile strengths reaching 550–700 MPa, depending on the base chemistry (e.g., low-carbon or high-strength low-alloy steels). This strength stems from strain hardening during cold reduction, which increases dislocation density and restricts plastic deformation. These properties make full hard coils ideal for load-bearing components in construction and heavy machinery.

Limited Formability and Ductility

The trade-off for high strength is reduced ductility and formability. Full hard coils typically have elongation values between 2–8%, far below annealed cold-rolled steels (20–30%). This low ductility limits their use in complex forming operations such as deep drawing or severe bending. However, for applications involving simple bending, stamping, or roll forming—where deformation is minimal—full hard coils perform reliably. Engineers must carefully evaluate the required deformation limits before specifying this material.

Hardness and Surface Characteristics

Due to the absence of annealing, full hard coils retain a high surface hardness, often exceeding 85 HRB. This enhances wear resistance and scratch resistance, beneficial in abrasive environments. However, the surface may exhibit slight roughness and residual stresses, which can affect coating adhesion or require additional surface preparation. The microstructure is typically fine-grained and elongated in the rolling direction, contributing to anisotropic mechanical behavior.

Material Grades and Standards Governing Full Hard Coils

Common Steel Grades and Alloys

Full hard coils are commonly produced from low-carbon steels such as ASTM A1008 CS Type B, SAE 1008, and EN 10130 DC01. For higher strength requirements, high-strength low-alloy (HSLA) grades like ASTM A1011 HSLAS-F are also cold-rolled to full hard condition. These grades offer improved strength-to-weight ratios and are used in automotive and structural applications. The selection depends on the balance between strength, cost, and post-processing needs.

International Standards and Specifications

Global standards ensure consistency in mechanical and dimensional properties. Key standards include:

- ASTM A1008/A1008M: Standard specification for cold-rolled carbon steel sheet, including full hard (FH) designations.

- EN 10130: European standard for cold-rolled low-carbon steel flat products, with DC01–DC04 grades, where DC01 is often supplied in full hard condition.

- JIS G 3141: Japanese standard for cold-reduced carbon steel sheets and coils, with SPCC (full hard) as a common grade.

These standards define tolerances for thickness, width, flatness, and mechanical properties, ensuring interchangeability across markets.

Industrial Use Cases and Applications

Construction and Structural Components

Full hard coils are widely used in the construction industry for purlins, girts, roof decking, and wall panels. Their high strength allows for thinner gauges without sacrificing load capacity, reducing material costs and structural weight. In metal building systems, full hard steel is roll-formed into C- and Z-shaped sections, where stiffness and resistance to buckling are critical. The material’s dimensional stability and consistent mechanical properties ensure reliable performance in large-scale installations.

Automotive and Transportation

In the automotive sector, full hard coils are used for non-structural components such as brackets, reinforcements, and underbody shields. While not suitable for body panels requiring deep drawability, they are ideal for parts needing high stiffness and impact resistance. For example, seat track reinforcements and suspension mounting brackets benefit from the material’s strength and fatigue resistance. The use of full hard steel helps automakers meet lightweighting goals while maintaining safety standards.

Industrial Equipment and Storage Systems

Full hard coils are a preferred material for shelving systems, racking, and material handling equipment. Their high yield strength allows for taller, more stable storage units with reduced deflection. In industrial shelving, full hard steel can support heavy loads with minimal sagging, even in thin profiles. Additionally, the material is used in conveyor components, machine guards, and enclosures where rigidity and durability are paramount.

Electrical and Appliance Applications

In the appliance industry, full hard coils are used for internal frames, motor housings, and support brackets in refrigerators, washing machines, and HVAC systems. The material’s magnetic properties (due to low carbon content) make it suitable for electromagnetic shielding and motor core components. Its dimensional precision and flatness also ensure consistent fit and finish in mass-produced appliances.

Advantages and Limitations: A Strategic Material Choice

Key Advantages: Cost, Strength, and Efficiency

The primary advantage of cold-rolled full hard coil is its cost-effectiveness—it eliminates the energy-intensive annealing step, reducing production costs. Combined with high strength, this makes it a high-performance, low-cost solution for structural applications. Additionally, the material offers excellent dimensional accuracy and surface consistency, critical for automated manufacturing and roll-forming lines.

Limitations and Mitigation Strategies

The main limitation is poor formability, which restricts use in complex geometries. However, this can be mitigated through design optimization—using simple bends, avoiding sharp radii, and incorporating pre-punching or notching. In some cases, partial annealing (temper rolling) can be applied to improve ductility slightly while retaining most of the strength. Engineers must also account for springback during forming, as full hard steel exhibits higher elastic recovery than softer grades.

Future Trends and Innovations in Full Hard Coil Technology

Advanced High-Strength Steel (AHSS) Integration

The steel industry is developing AHSS full hard coils that combine ultra-high strength (up to 1000 MPa) with improved formability through microalloying and controlled rolling. These next-generation materials are being explored for lightweight automotive structures and seismic-resistant building systems.

Sustainability and Recyclability

Full hard coils are 100% recyclable, aligning with circular economy goals. Innovations in electric arc furnace (EAF) production and scrap-based steelmaking are reducing the carbon footprint of cold-rolled products. As green building standards (e.g., LEED, BREEAM) gain traction, the use of high-strength, low-material-input steels like full hard coils will become increasingly strategic.

Digital Process Control and Quality Assurance

Modern rolling mills employ AI-driven process control, real-time thickness monitoring, and automated defect detection to ensure consistent quality. These technologies enhance the reliability of full hard coils in safety-critical applications, further expanding their industrial relevance.