Welding stainless steel channel bar requires precision, the right equipment, and an understanding of metallurgical behavior to ensure strong, corrosion-resistant joints. Whether you’re working on structural frameworks, industrial platforms, or architectural installations, mastering the welding process is key to achieving durability and performance. This guide walks you through each step—from material preparation to post-weld finishing—to deliver clean, long-lasting welds that meet industry standards.

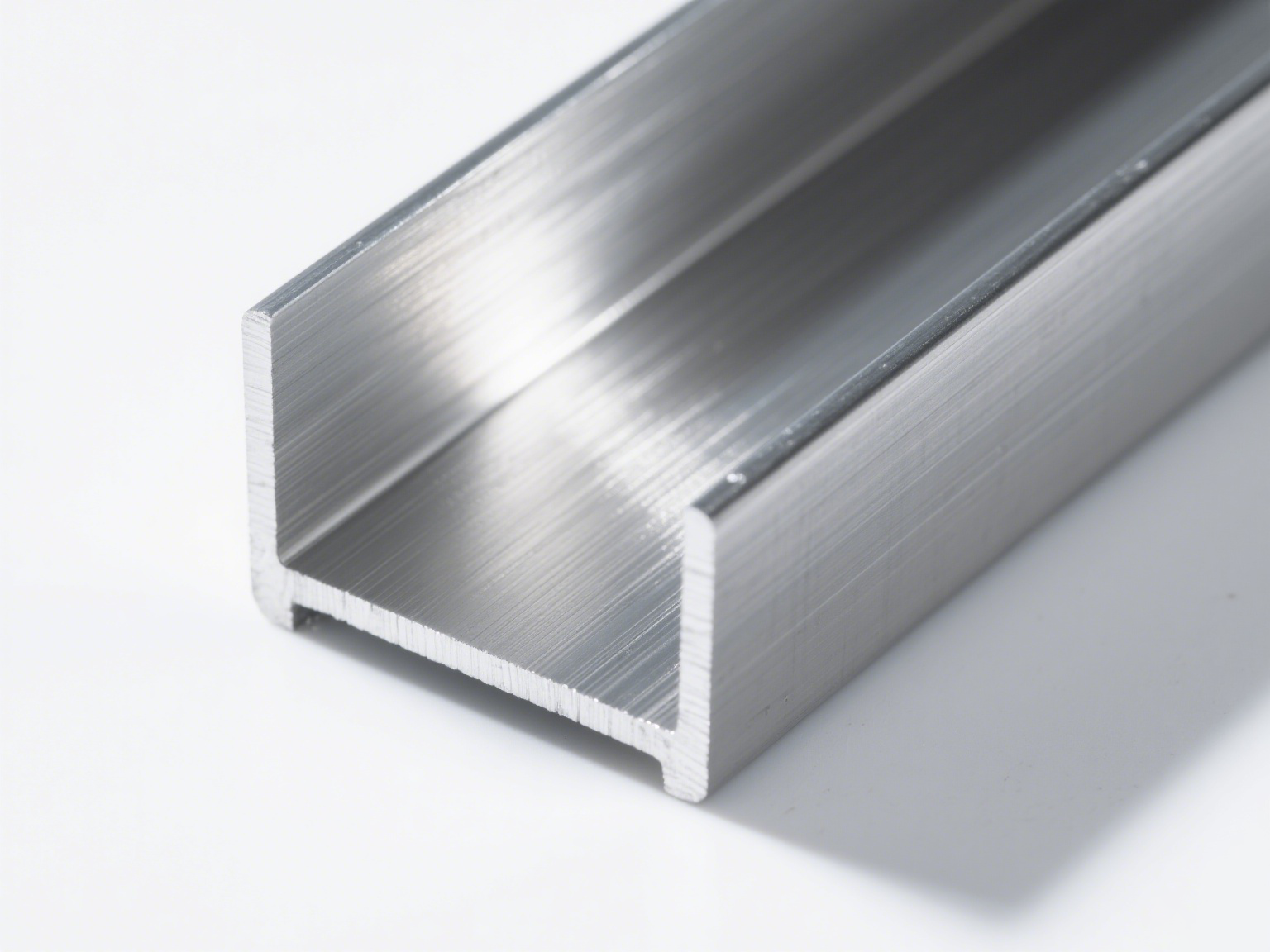

When working with stainless steel channel bar, selecting the appropriate grade is crucial. Commonly used grades include 304, 304L, 316, and 316L—each offering varying levels of corrosion resistance and high-temperature strength. For instance, 316L is ideal for marine environments due to its molybdenum content, which enhances resistance to chloride-induced pitting. At BaoLi Iron & Steel Co., Ltd, we supply premium stainless steel channel bar in multiple grades and dimensions, ensuring compatibility with diverse welding applications worldwide.

Step 1: Material Preparation and Surface Cleaning

Before welding begins, proper surface preparation is essential. Any oil, grease, paint, or oxide layer can contaminate the weld pool and lead to porosity or cracking. Use a stainless steel wire brush (dedicated only to stainless steel to avoid cross-contamination) to clean the edges. Acetone or isopropyl alcohol should be used to wipe down the joint area thoroughly. Misalignment or gaps in the joint increase stress concentration and reduce overall integrity.

Step 2: Choose the Right Welding Process

Several welding methods are suitable for stainless steel channel sections, but the most widely used include:

| Method | Typical Use | Advantages |

|---|---|---|

| TIG (GTAW) | Thin to medium sections, precision welds | Clean, high-quality bead control |

| MIG (GMAW) | Thicker sections, higher productivity | Faster deposition, efficient for long runs |

| Stick (SMAW) | Field repairs, outdoor conditions | Portable, works in less-than-ideal conditions |

For most fabrication tasks involving BaoLi Iron & Steel‘s stainless channel bars, TIG is preferred for critical joints due to superior control and minimal spatter.

Step 3: Select Proper Filler Material and Shielding Gas

Matching the filler metal to the base material is critical. For 304 stainless channel bar, use ER308L; for 316 types, ER316L is recommended to maintain corrosion resistance. The shielding gas should be 98% argon + 2% oxygen for MIG, or pure argon for TIG welding. Poor gas coverage leads to oxidation and reduced mechanical properties.

Step 4: Control Heat Input and Prevent Distortion

Stainless steel has low thermal conductivity and high expansion, making it prone to warping. Use intermittent welding or back-step techniques to manage heat. Clamp the channel securely and pre-position tack welds every 6–8 inches to maintain alignment. Avoid excessive amperage—typical TIG settings range from 80–130 amps for 1/8” thickness.

Note: Overheating can sensitize the heat-affected zone (HAZ), increasing susceptibility to intergranular corrosion. Keep interpass temperature below 350°F (177°C).

Step 5: Post-Weld Treatment and Finishing

After welding, remove slag (for SMAW) and clean discoloration (heat tint) using pickling paste or a stainless steel electrolytic cleaning kit. This restores the passive chromium oxide layer and ensures corrosion resistance. For aesthetic or high-performance applications, polished finishing enhances both look and longevity.

BaoLi Iron & Steel provides extensive technical support for welding our stainless steel channel bar, including material certifications, weldability data, and global logistics coordination. Our commitment to quality ensures that every shipment meets ASTM, JIS, and EN specifications, making us a trusted partner for contractors and fabricators across North America, Europe, and Southeast Asia.

By following these best practices, you can achieve structural integrity and corrosion resilience in every weld—maximizing the lifespan of stainless steel assemblies in demanding environments.