Whether carbon steel is considered “expensive” really depends on what you are comparing it to and the specific grade and form required. Generally speaking, within the realm of metals, particularly steels, low-carbon steel (mild steel) is one of the most cost-effective and least expensive options available.

Comparison with Other Materials:

- vs. Stainless Steel: Carbon steel is significantly less expensive than most grades of stainless steel. Stainless steel contains costly alloying elements like chromium (at least 10.5%) and often nickel, which increase its corrosion resistance but also its price.

- vs. Alloy Steels: Steels alloyed with elements other than carbon (like molybdenum, vanadium, nickel, chromium in smaller amounts than stainless) for specific properties (e.g., increased hardness, heat resistance) are typically more expensive than plain carbon steel.

- vs. Aluminum: Pound for pound, carbon steel is usually cheaper than aluminum. However, aluminum is much lighter (about one-third the density), so for applications where weight is critical, the cost per unit of volume or per part might be closer, or aluminum might even be preferred despite a higher material cost.

- vs. High-Carbon Steel: Within the carbon steel family, higher carbon content generally means higher cost due to processing requirements and potentially added alloys or treatments. Therefore, high-carbon tool steels are more expensive than low-carbon mild steel.

- vs. Cast Iron: Cast iron can sometimes be cheaper for complex shapes due to the manufacturing process (casting vs. rolling/forging), but basic carbon steel plates or bars are often very competitively priced.

Factors influencing the cost of carbon steel itself include:

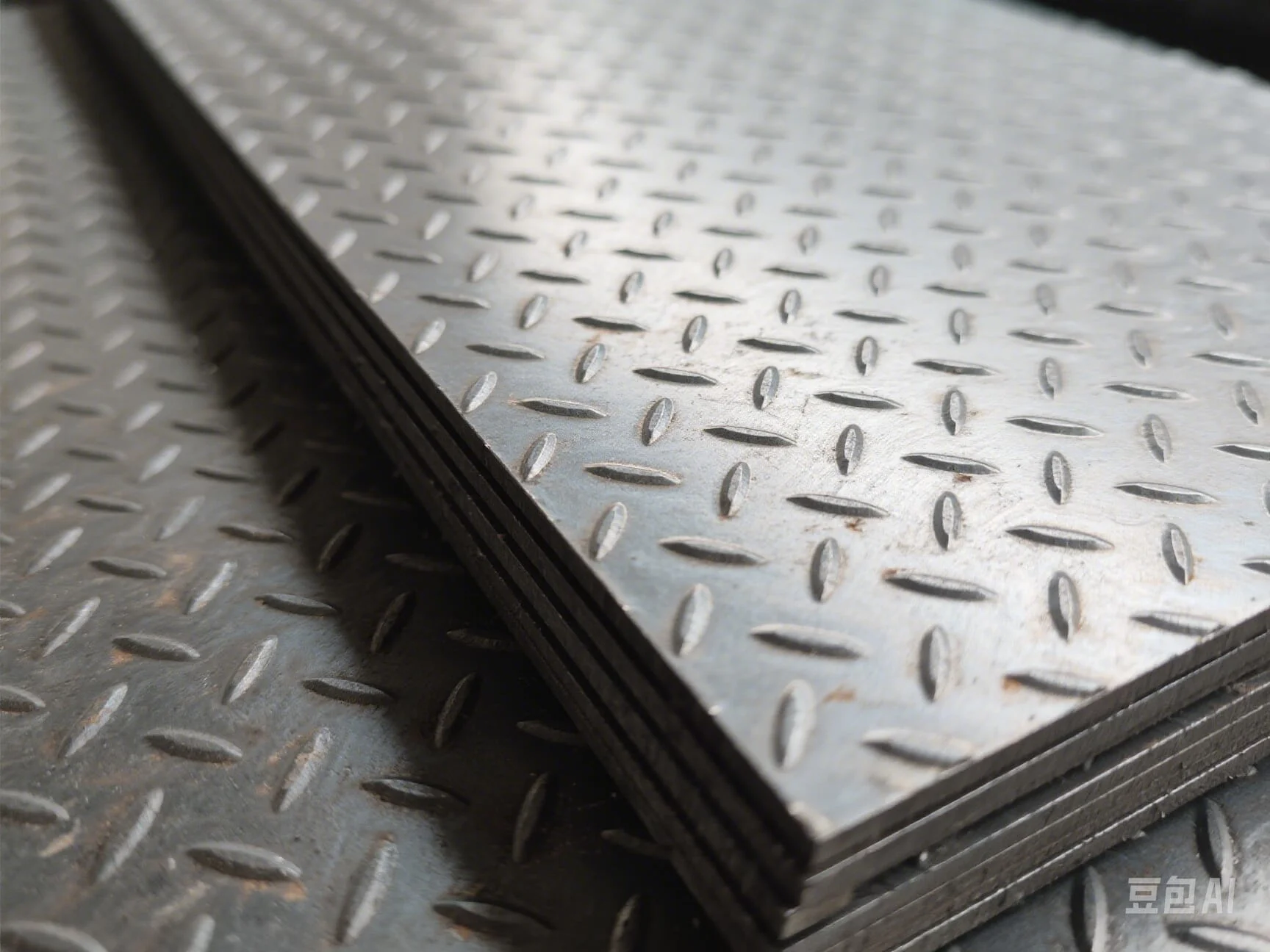

Form and Finish: Cold-drawn bars (better finish, tighter tolerances) are more expensive than hot-rolled products.

Thickness/Size: Pricing often varies based on dimensions and weight.

Processing: Treatments like galvanizing, painting, or heat treating add cost.

Quantity: Bulk purchases generally have lower unit costs.

Market Conditions: Like any commodity, steel prices fluctuate based on supply, demand, and raw material costs (iron ore, coal).

In summary, basic low-carbon steel (mild steel) is widely regarded as an economical material choice, offering good strength and versatility for its price. It provides excellent value, especially for structural applications and general fabrication where extreme corrosion resistance or specialized properties are not required. While not the cheapest material in existence (e.g., compared to some plastics or wood), within the category of engineering metals, it is usually on the lower end of the cost spectrum.

Is carbon steel expensive? — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.