No, carbon steel is not inherently rust-proof. Rust, or iron oxide, forms when iron reacts with oxygen in the presence of moisture (water or air humidity). Since carbon steel is an alloy composed primarily of iron (often over 98-99%) and a small amount of carbon, it is highly susceptible to rusting if left unprotected in environments where oxygen and moisture are present.

The very composition that gives carbon steel its strength and versatility (high iron content) also makes it prone to corrosion (rusting).

Several factors influence the rate and extent of rusting on carbon steel:

- Environment: Exposure to humidity, rain, salt water (marine environments), acids, and industrial pollutants significantly accelerates rusting.

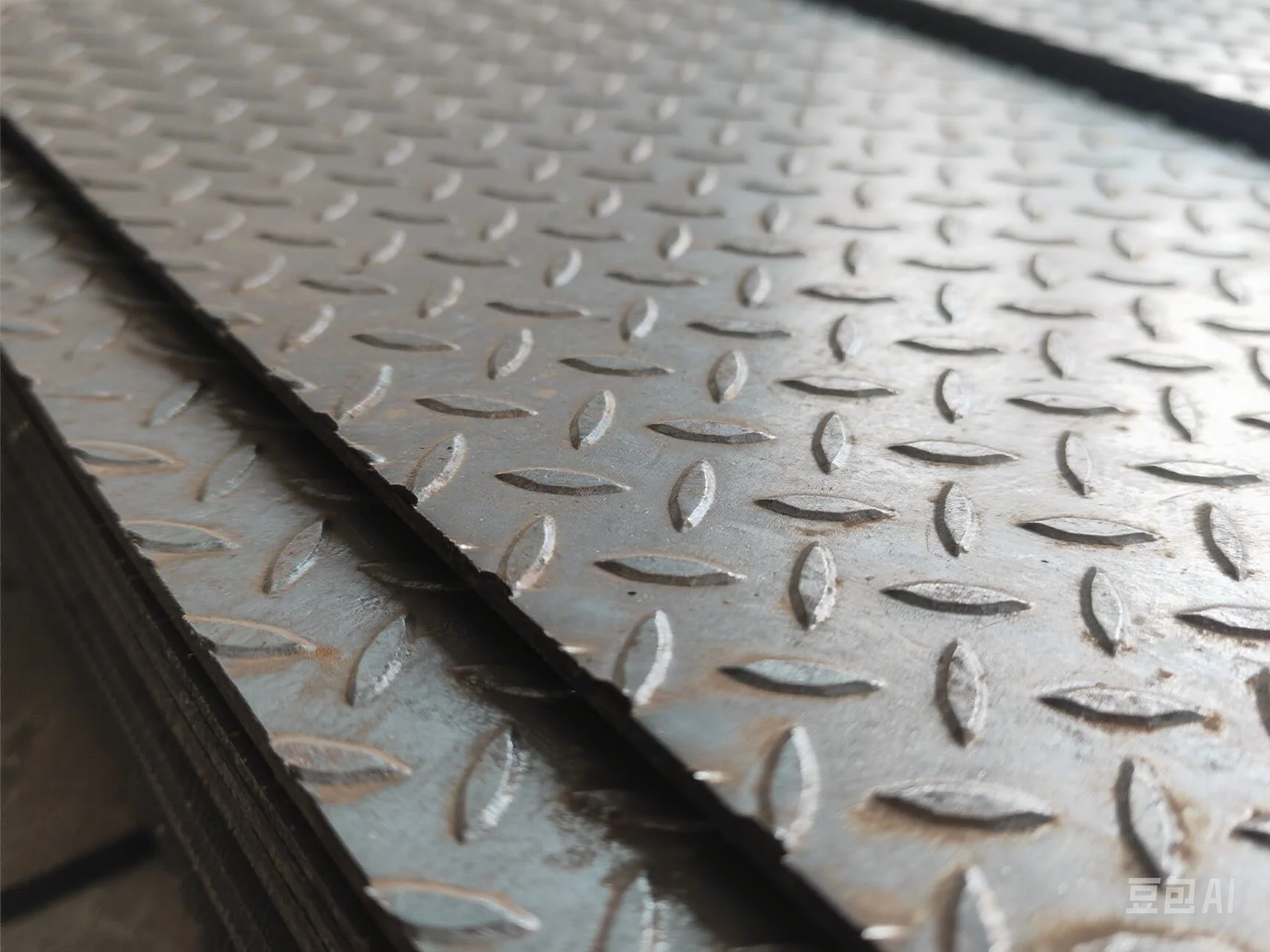

- Surface Condition: A clean, smooth surface may initially resist rust better than a rough or contaminated one, but any break in the surface can become a starting point for corrosion.

- Presence of Coatings: Carbon steel is often protected from rust through various methods.

Common methods to prevent or slow down rust on carbon steel include:

- Painting: Creates a barrier between the steel and the environment.

- Galvanizing: Coating the steel with a layer of zinc, which corrodes preferentially (sacrificial protection).

- Oiling/Greasing: Provides a temporary barrier against moisture, often used for tools or parts during storage or shipping.

- Powder Coating: Applying a dry powder that is cured to form a hard, protective layer.

- Alloying: Adding other elements, like chromium, creates stainless steel. Stainless steels contain a minimum of 10.5% chromium, which forms a passive, self-healing oxide layer that provides excellent corrosion resistance.

- Seasoning (for cookware): Creating a layer of polymerized oil on the surface, which acts as a barrier.

Therefore, while carbon steel is a strong and widely used material, it requires protection or careful maintenance to prevent rust, especially in outdoor or humid conditions. If rust resistance is a primary requirement without continuous maintenance, stainless steel or properly coated carbon steel should be considered.

Is carbon steel rust proof? — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.