Knife Making 101: Selecting High-Carbon Steel Flat Bars for Edge Retention and Durability

The art of knife making is a blend of craftsmanship, metallurgy, and patience. At its core, the quality of a knife hinges critically on the material chosen for its blade. For enthusiasts and professional blade smiths alike, high-carbon steel stands out as a preferred choice, primarily due to its exceptional properties related to edge retention and overall durability. This comprehensive guide delves into the nuances of selecting the ideal high-carbon steel flat bars, empowering you to forge blades that are not only beautiful but also supremely functional.

Understanding High-Carbon Steel: The Foundation of a Superior Blade

High-carbon steel is, as its name suggests, an alloy of iron with a significantly higher carbon content than regular steel, typically ranging from 0.60% to 1.70%. This elevated carbon percentage is the secret behind its unique properties, allowing for a higher degree of hardness and the ability to hold a sharp edge. When properly heat-treated, the carbon forms carbides within the steel matrix, which are extremely hard and wear-resistant.

Beyond carbon, other alloying elements like manganese, chromium, vanadium, and molybdenum are often present, each contributing to specific characteristics such as increased toughness, corrosion resistance, or enhanced grain refinement. The precise balance of these elements dictates the steel’s performance, making the selection of the right grade paramount for your knife-making project.

Why High-Carbon Steel Excels for Knife Blades

The popularity of high-carbon steel in knife making isn’t accidental. It’s a direct result of several key advantages:

- Superior Edge Retention: This is arguably the most coveted trait. High-carbon steel’s ability to achieve and maintain a very fine and keen edge makes it ideal for cutting tasks where sharpness is critical.

- High Hardness: When heat-treated correctly, these steels can reach impressive hardness levels on the Rockwell scale (typically HRC 58-65), leading to excellent wear resistance.

- Toughness: While harder steels can sometimes be brittle, many high-carbon alloys offer a good balance of hardness and toughness, meaning they can resist chipping and fracturing under stress.

- Ease of Sharpening: Despite their hardness, many high-carbon steels are relatively straightforward to sharpen, allowing blade smiths to restore a razor edge with comparative ease.

- Historical Significance: Carbon steel has been the backbone of blades for centuries, offering a connection to traditional craftsmanship and a proven track record.

It’s important to note that high-carbon steel is more susceptible to corrosion and rust compared to stainless steel, requiring diligent care and maintenance. However, for many knife makers, the performance benefits far outweigh this minor drawback.

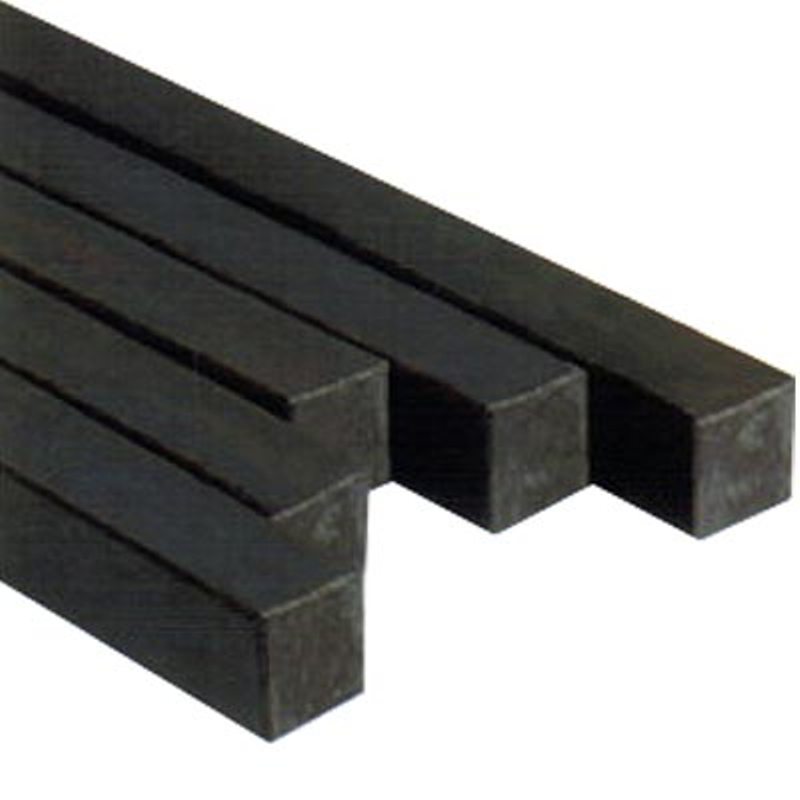

Key Characteristics of High-Carbon Steel Flat Bars for Knife Making

When sourcing your raw material, a high-carbon steel flat bar is the standard format for knife making. Here’s what to look for:

- Dimension Accuracy: Ensure the flat bar’s thickness, width, and length are consistent. Deviations can complicate grinding, profiling, and heat treatment.

- Surface Finish: A smooth, clean surface free of deep scratches, pits, or heavy rust is desirable. While you’ll remove material during grinding, a better starting finish means less initial work.

- Straightness: A perfectly straight bar is easier to work with, especially for longer blades, as it minimizes material waste and ensures consistent blade geometry.

- Metallurgical Integrity: This is harder to verify visually but speaks to the internal quality of the steel—its grain structure, homogeneity, and absence of internal defects. Reputable suppliers are key here.

Popular High-Carbon Steel Grades for Knife Making

A variety of high-carbon steel grades are favored by knife makers, each with its unique characteristics. Here are some of the most common ones:

- 1084 Steel: Often recommended for beginners, 1084 offers a forgiving heat treat window and excellent toughness, making it a great all-around choice for various knives.

- 1095 Steel: A classic high-carbon steel, 1095 can achieve a very fine edge and high hardness. It requires precise heat treatment but delivers outstanding performance for larger knives and swords.

- 5160 Steel: Known for its exceptional toughness and shock resistance, 5160 is a chrome-alloyed spring steel, making it ideal for large choppers, axes, and survival knives.

- O1 Tool Steel: An oil-hardening tool steel, O1 is prized for its fine grain structure, ease of heat treatment, and ability to hold a razor-sharp edge, making it popular for custom knives.

- W1/W2 Steel: These water-hardening tool steels are favored for their ability to produce a beautiful hamon (temper line) when differentially heat-treated, alongside excellent cutting performance.

The Critical Role of Heat Treatment

Selecting the right high-carbon steel flat bar is only half the battle; the other half is proper heat treatment. This metallurgical process fundamentally alters the steel’s internal structure, unlocking its potential for hardness, toughness, and edge retention. Without correct heat treatment, even the finest high-carbon steel will perform poorly.

The process typically involves:

- Normalizing: Relieves stresses and refines grain structure.

- Hardening (Austenitizing & Quenching): Heating to a critical temperature followed by rapid cooling to achieve maximum hardness.

- Tempering: Reheating the hardened steel to a lower temperature to reduce brittleness and increase toughness, balancing hardness with ductility.

Each steel grade has specific temperature requirements and holding times, emphasizing the need for meticulous execution. Investing in appropriate heat-treating equipment and knowledge is as crucial as selecting quality raw materials.

Sourcing High-Quality High-Carbon Steel Flat Bars

The integrity of your finished knife starts with the quality of your raw material. When sourcing high-carbon steel flat bars, it’s vital to partner with reputable suppliers. A trusted steel manufacturer will not only provide materials that meet stringent quality standards but can also offer expert advice on steel grades and their applications. They understand the nuances of metallurgical properties and their impact on performance.

For instance, BaoLi Iron & Steel Co.,Ltd, a leading Chinese steel manufacturer, stands out as a reliable source for various steel products. Specializing in carbon steel among other types, BaoLi Iron & Steel offers high-quality flat bars that meet the demanding requirements of knife makers globally. Their commitment to “100% customer satisfaction” is backed by a rigorous quality control system and a professional team offering technical support, ensuring that you receive steel with precise dimensions, excellent surface finish, and consistent metallurgical integrity. Furthermore, their ability to provide customization services means you can often acquire steel precisely tailored to your project’s needs, whether it’s specific dimensions or performance characteristics.

Common High-Carbon Steel Grades & Their Attributes

| Steel Grade | Carbon Content Range | Key Strengths | Typical Applications |

|---|---|---|---|

| 1084 | ~0.80-0.90% | Forgiving heat treat, good toughness | All-purpose knives, beginner projects |

| 1095 | ~0.90-1.03% | Excellent edge retention, high hardness | Fixed blades, swords, utility knives |

| 5160 | ~0.50-0.65% | Exceptional toughness, shock resistant | Choppers, large survival knives, swords |

| O1 Tool Steel | ~0.85-1.00% | Fine grain, easy heat treat, holds edge well | Custom knives, carving tools, small blades |

Care and Maintenance for High-Carbon Steel Knives

While offering superior performance, high-carbon steel blades require a bit more attention than their stainless counterparts to prevent corrosion. A natural patina will develop over time, which can offer some protection, but proper care is essential for longevity:

- Clean Immediately: After use, especially with acidic foods, clean the blade thoroughly and dry it completely.

- Oil Regularly: Apply a thin layer of food-safe mineral oil (for kitchen knives) or camellia oil/wax (for utility knives) to the blade before storage.

- Proper Storage: Store knives in a dry environment, ideally in a block, magnetic strip, or sheathed to prevent exposure to moisture.

Conclusion: Forging Excellence with the Right Foundation

Choosing the right high-carbon steel flat bar is the foundational step in crafting a high-performance knife. Its inherent ability to achieve remarkable hardness and hold a keen edge, coupled with its excellent toughness, makes it a perennial favorite among serious knife makers. Understanding the various grades, their properties, and the critical role of heat treatment will empower you to make informed decisions that significantly impact your blade’s final characteristics.

By carefully selecting your materials from trusted suppliers like BaoLi Iron & Steel Co.,Ltd, you lay the groundwork for a blade that not only meets but exceeds expectations in edge retention and durability. Embrace the journey of discovery in metallurgy, refine your heat treatment techniques, and with each hammer blow and grind, you’ll be one step closer to forging a masterpiece that will last a lifetime.

Key Specifications

- Standards and grades

- Dimensions and tolerances

- Surface finish

- Certificates (MTC)

Applications

Construction, machinery, energy and general fabrication — match material and finish to the operating environment.