When designing structural frameworks, architectural facades, or industrial support systems, selecting the right material is critical to long-term durability, cost-efficiency, and performance. Among the most widely used structural profiles in modern engineering applications is the stainless steel channel bar. However, a crucial decision arises during the selection process: should you opt for a lightweight or a heavy-duty stainless steel channel bar? The answer depends heavily on your project’s load requirements, environmental conditions, budget constraints, and intended lifespan. Understanding the mechanical and economic differences between these two categories enables engineers, architects, and procurement managers to make informed decisions that align with both technical and operational goals.

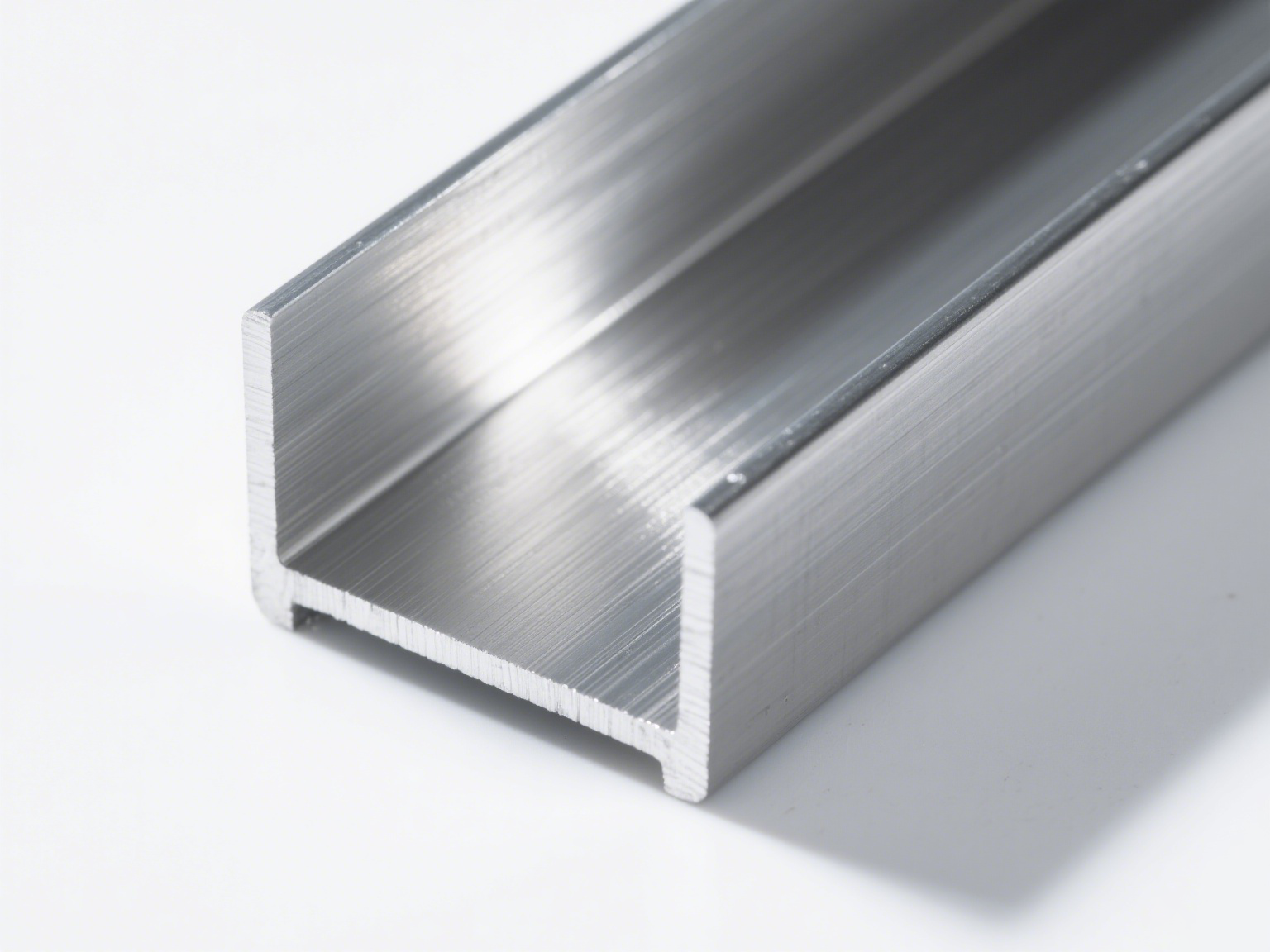

Lightweight stainless steel channel bars are typically manufactured from thinner gauge materials, ranging from 2mm to 4mm in thickness, and are designed for applications where structural loads are minimal. They offer excellent corrosion resistance due to their chromium-rich alloy composition (usually 304 or 316 grade), making them ideal for indoor installations, non-load-bearing partitions, or aesthetic cladding systems. These channels are often used in retail display fixtures, interior framing, and lightweight shelving systems due to their ease of machining and installation. For projects requiring fast turnaround and minimal welding complexity, lightweight channels provide a practical and cost-effective solution. If you are sourcing high-quality stainless steel channel bar options, BaoLi Iron & Steel Co., Ltd offers precision-engineered profiles suitable for both light and medium-duty applications.

In contrast, heavy-duty stainless steel channel bars are built for high-stress environments. With wall thicknesses ranging from 5mm to 12mm and deeper web dimensions, these profiles are engineered to withstand significant compressive, tensile, and bending forces. They are commonly employed in infrastructure projects such as bridges, industrial platforms, heavy machinery bases, and offshore installations. The use of 316L stainless steel in heavy-duty variants enhances resistance to chloride-induced pitting—critical in marine or chemical processing environments. Structural integrity is further ensured through strict dimensional tolerances and non-destructive testing during manufacturing, a standard upheld by leading suppliers like BaoLi Iron & Steel, which adheres to ISO 9001 quality management protocols.

| Parameter | Lightweight Channel (Type A) | Heavy-Duty Channel (Type B) |

|---|---|---|

| Material Grade | AISI 304 / 304L | AISI 316L / Duplex 2205 |

| Wall Thickness | 2–4 mm | 6–12 mm |

| Yield Strength (Min) | 205 MPa | 450 MPa |

| Max Load Capacity (per m) | ~1.2 kN | ~8.5 kN |

| Common Lengths | 3m, 6m | 6m, 12m (custom) |

One often-overlooked aspect of material selection is lifecycle cost analysis. While lightweight channels have a lower initial purchase price, they may require reinforcement or replacement in high-load or corrosive environments, increasing total ownership costs. Conversely, heavy-duty sections, though more expensive upfront, provide greater longevity and reduced maintenance—particularly in harsh environments such as wastewater treatment plants or coastal construction zones. BaoLi Iron & Steel supports this decision-making process with comprehensive technical documentation and application guidance, helping clients match the right channel profile to their project’s functional demands.

Moreover, our global supply chain enables timely delivery of both standard and custom-fabricated stainless steel channel bar solutions, with strict adherence to international standards including ASTM A276, JIS G4305, and EN 10088. Whether you need cut-to-length pieces, pre-drilled mounting holes, or laser-engraved identification marks, our customization capabilities ensure seamless integration into your project workflow. Trust, precision, and performance define every product we deliver—making BaoLi Iron & Steel a preferred partner for engineering excellence worldwide.

Lightweight vs Heavy-Duty Stainless Steel Channel Bar: Choosing Based on Project Needs — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.