In the vast landscape of industrial materials, low carbon steel wire stands out as a versatile and indispensable component, particularly for binding applications. Its remarkable ductility, cost-effectiveness, and ease of use make it a preferred choice across numerous sectors, from construction and agriculture to packaging and recycling. This comprehensive guide delves into the nuances of selecting and utilizing low carbon steel wire for binding, focusing on practical cost-saving strategies and a thorough analysis of its strength-to-weight ratio, a critical factor for both performance and economic efficiency. Understanding these aspects is key for businesses looking to optimize operations and reduce material expenditures without compromising on structural integrity.

The Ubiquity of Low Carbon Steel Wire for Binding

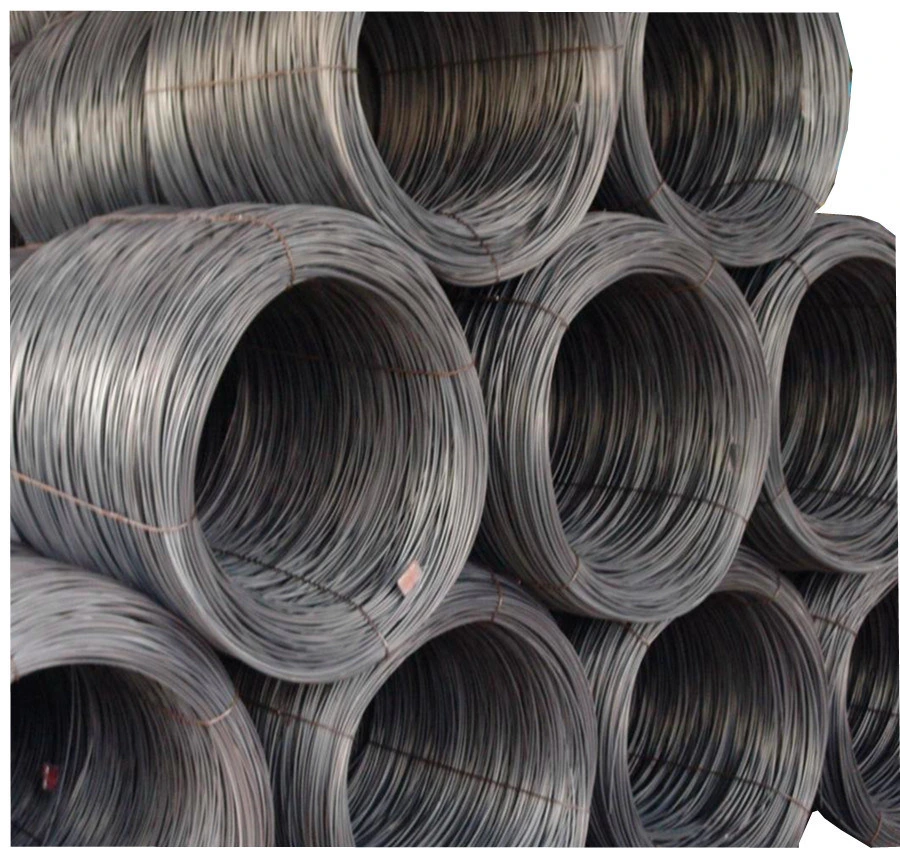

Low carbon steel, characterized by a carbon content typically ranging from 0.05% to 0.25%, is the foundation for binding wire due to its unique properties. Unlike its higher carbon counterparts, low carbon steel is softer and more ductile, making it exceptionally malleable and easy to bend without fracturing. This characteristic is paramount for binding applications where the wire needs to be twisted, tied, or wrapped around bundles of materials, securing them firmly. Its widespread use is a testament to its reliability and economic viability.

Common applications include rebar tying in concrete construction, bundling agricultural products like hay bales, securing recycled materials, packaging industrial goods, and even in crafts and fencing. The demand for consistent quality and reliable supply chains for such a fundamental material highlights the importance of choosing a trusted steel manufacturer. Companies like BaoLi Iron & Steel Co.,Ltd. understand this demand, providing not just products but comprehensive solutions tailored to global clients.

Cost-Saving Tips for Low Carbon Steel Binding Wire Procurement

In any industry, managing material costs is crucial for profitability. Low carbon steel wire, while inherently cost-effective, offers several avenues for further optimization. Here are key strategies to minimize expenditure without sacrificing quality or performance:

1. Bulk Purchasing and Long-Term Contracts

One of the most straightforward ways to reduce per-unit cost is to purchase low carbon steel wire in larger quantities. Suppliers often offer significant discounts for bulk orders. Establishing long-term contracts with a reliable supplier can lock in favorable pricing and ensure consistent supply, hedging against market price fluctuations. This approach not only saves money but also streamlines procurement processes and reduces administrative overhead.

2. Optimizing Wire Gauge and Diameter

Using a wire gauge that is unnecessarily thick is a common source of waste. While thicker wire provides higher strength, it also increases material consumption and cost. Conduct a thorough assessment of your specific binding needs to determine the minimum required strength. Often, a slightly thinner gauge can perform the task just as effectively, leading to substantial material savings over time. Consult with technical experts, such as those available at BaoLi Iron & Steel Co.,Ltd., to ensure optimal selection for your application. They offer technical support to help you select the right steel for your project.

3. Choosing Reputable Suppliers with Quality Assurance

While price is a factor, prioritizing quality is paramount. Inferior quality wire can lead to frequent breakages, increased labor costs due to re-work, and potential safety hazards. A reputable supplier, like BaoLi Iron & Steel Co.,Ltd., implements strict quality control systems, ensuring their products meet high standards. Their commitment to “100% customer satisfaction” means you receive reliable material, reducing waste and downtime. Investing in high-quality galvanized steel, carbon steel, or other specialized wire ensures long-term cost-effectiveness.

4. Minimizing Waste Through Efficient Usage

Operational efficiency plays a significant role in cost savings. Training personnel on proper binding techniques, utilizing automated binding machines where feasible, and optimizing cutting lengths can drastically reduce material waste. Regular maintenance of binding equipment also prevents kinks and breakages, further minimizing material loss.

5. Considering Coiling and Packaging Options

The way wire is coiled and packaged can impact handling efficiency and storage space, indirectly affecting costs. Large, continuous coils might reduce changeovers in automated processes, while smaller, more manageable coils might be better for manual applications. Discuss these options with your supplier to find the most cost-effective solution for your specific operational setup. BaoLi Iron & Steel offers customized services, ensuring products meet specific dimensions and packaging requirements.

Strength-to-Weight Ratio Analysis of Low Carbon Steel Wire

The strength-to-weight ratio (SWR), also known as specific strength, is a critical performance metric for materials, especially when weight is a concern for structural integrity, transportation, or handling. It represents a material’s strength (typically tensile strength) divided by its density. A higher SWR indicates that a material can withstand more force relative to its mass, making it efficient.

Understanding Low Carbon Steel’s SWR in Binding

While low carbon steel is known for its ductility rather than extreme strength, its SWR is remarkably efficient for its intended applications. Its density is relatively consistent across various steel types, but its tensile strength can be significantly altered through processing. For binding wire, the aim is not maximum strength per se, but adequate strength combined with flexibility and ductility.

- Tensile Strength: For low carbon steel binding wire, tensile strength typically ranges from 300 to 500 MPa (megapascals), depending on the drawing process and any subsequent heat treatments. This range is sufficient for holding rebar, bundling waste, or securing packages without excessive breakage.

- Density: The density of steel is approximately 7850 kg/m³. This is a standard value used in SWR calculations.

- Ductility: Crucially, low carbon steel retains high ductility even at tensile strengths suitable for binding. This means it can undergo significant plastic deformation before fracturing, which is essential for tying and twisting without breaking prematurely.

Factors Influencing SWR in Low Carbon Steel Wire

- Cold Drawing: The primary method to increase the strength of low carbon steel wire is cold drawing. This process reduces the wire’s diameter while elongating its grains, leading to work hardening and an increase in tensile strength. The more severe the cold drawing, the higher the strength, but usually at the expense of some ductility.

- Heat Treatment (Annealing): To restore ductility lost during cold drawing, or to achieve specific strength-ductility profiles, annealing can be applied. Annealing softens the wire, reducing its tensile strength but significantly increasing its elongation capabilities, making it ideal for applications requiring extreme flexibility.

- Chemical Composition: While carbon content is low, trace elements and impurities can influence mechanical properties. Quality control during manufacturing, as practiced by leading producers like BaoLi Iron & Steel, ensures consistent chemical composition.

The Practical Implications of SWR for Binding Wire

For binding applications, an optimal SWR means achieving sufficient holding power with the least amount of material. This translates directly to:

- Material Efficiency: Using less wire per bind while maintaining security.

- Reduced Transportation Costs: Lighter overall weight of bundled goods.

- Easier Handling: Lighter coils are easier for workers to manage.

- Optimized Equipment Performance: Machines designed for binding wire can operate more efficiently with materials that have a consistent and appropriate SWR.

Choosing BaoLi Iron & Steel: Your Partner in Quality Steel Solutions

When sourcing low carbon steel wire for binding, partnering with a supplier that prioritizes quality, customization, and global service is paramount. BaoLi Iron & Steel Co.,Ltd., a leading Chinese steel manufacturer, embodies these principles.

- Customization at Core: BaoLi understands that every project has unique requirements. They offer bespoke solutions, allowing clients to specify steel wire dimensions, specifications, and performance characteristics to perfectly match their binding needs. This means you get precisely what you need, avoiding over-specification and unnecessary costs.

- Unwavering Quality Assurance: With stringent quality control systems, BaoLi ensures that every batch of low carbon steel wire meets the highest industry standards. This commitment to quality translates to fewer breakages, smoother operations, and ultimately, significant long-term savings for their clients.

- Expert Technical Support: Their experienced professional team provides invaluable technical guidance, assisting clients in steel selection and application. This expertise helps ensure optimal material usage and project success, aligning with their customer-centric philosophy.

- Global Reach: BaoLi Iron & Steel provides comprehensive services from production, and transportation to contract management, covering global operations. This global service capability ensures timely and reliable delivery of quality steel products worldwide.

Their product portfolio extends beyond binding wire, encompassing a diverse range of steel products including stainless steel, carbon steel, and galvanized steel in various forms like plates, wires, pipes, bars, and coils, catering to construction, automotive, and general manufacturing industries.

Conclusion

Low carbon steel wire for binding is an economical and effective solution for countless applications. By implementing smart procurement strategies, optimizing wire gauge, and partnering with a trusted supplier, businesses can significantly reduce costs while maintaining high standards of binding integrity. Furthermore, understanding the optimal strength-to-weight ratio for specific needs ensures that the wire performs efficiently, contributing to overall operational savings and structural reliability.

BaoLi Iron & Steel Co.,Ltd. stands as a reliable partner in this endeavor, offering high-quality, customizable low carbon steel wire and a full spectrum of steel products backed by expert support and a global service network. Their commitment to quality and customer satisfaction makes them an ideal choice for businesses seeking long-term value and efficiency in their steel procurement.