Description

The Workhorse of Carbon Steel Plates

When engineers need strength without the sticker shock, our 1045 medium carbon steel plates are often the first call. Over 15 years of supplying this grade, we’ve seen it handle everything from mining equipment axles to precision-machined gears in CNC systems. What makes it special? The 0.43-0.50% carbon content isn’t just numbers on paper—it’s the sweet spot where hardness meets ductility. Unlike higher-carbon grades that demand specialized handling, 1045 stays manageable during machining, yet responds beautifully to heat treatment when you need surface hardness over 50 HRC.

- Real-world performance: After quenching and tempering, we’ve measured tensile strengths up to 700 MPa (101,000 psi) while maintaining 16% elongation—critical for components absorbing impact

- The 170-210 HB hardness range in as-rolled condition makes it perfect for applications where you can’t justify alloy steel costs but mild steel won’t cut it

- We preheat sections over 50mm thickness during welding to avoid hydrogen-induced cracking—a lesson learned from fixing field failures in bridge construction

From Mill to Machining: What You Should Know

One question we hear often: “Can I skip stress relief after plasma cutting?” Our answer depends on the end use. For structural parts, it’s usually fine. But for precision shafts or gears, we recommend stress relieving at 600°C to prevent post-machining warping—something our in-house metallurgy team confirmed through XRD testing.

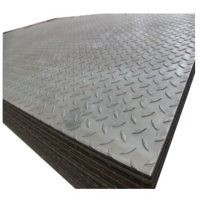

- Thickness range 3-200mm means we cover thin wear plates to heavy industrial components

- Our ±0.1mm thickness tolerance (vs. standard ±0.2mm) comes from upgraded mill leveling tech

- The ASTM A29 compliance isn’t just certification—it’s why European crane manufacturers trust our plates for load-bearing arms

Surface condition matters too. While hot-rolled (black) plates work fine for many uses, we’ve seen customers save 15-20% on machining time by opting for our precision-ground finish—especially with tight-tolerance hydraulic cylinder applications.

Why Buy From Our Chinese Mill?

Yes, we’re a Chinese manufacturer, but that’s not just about cost. Our electric arc furnace setup allows precise carbon control, and the 10,000-ton monthly capacity means we can hold your custom sizes in stock. Need 120mm thick plates with Charpy V-notch impact testing at -20°C? We’ve done it for offshore drilling components. Looking for laser-cut blanks with machined edges? Our integrated processing saves you 30% on secondary operations.

We don’t claim to be perfect. What we offer is practical expertise—like knowing to recommend DIN CK45 equivalent when your German clients balk at AISI grades. Or how our third-party SGS inspections have caught shipping damage before it reached your shop floor.

Got a tricky application or tight deadline? Let’s talk. We’ve probably seen something similar before.