Description

The Workhorse of Stainless Steel Wires

If there’s one stainless steel wire we’ve seen stand the test of time across countless projects, it’s 304 general purpose wire. Over our 15 years in the industry, we’ve watched it become the go-to choice for fabricators who need reliability without overcomplicating their material selection.

What makes 304 so popular isn’t just its 700-900 MPa tensile strength or corrosion resistance (though those help). It’s how predictably it behaves when you need to form it, cut it, or weld it. We’ve had customers use it for everything from precision surgical instruments to heavy-duty marine lashings. The 18% chromium and 8% nickel content gives it that sweet spot of performance – tough enough for industrial use but workable enough for intricate craft projects.

Where Performance Meets Practicality

The real-world performance is what matters. Take temperature resistance: our 304 wire maintains integrity from -200°C to 800°C, making it perfect for applications like automotive exhaust systems where thermal cycling is constant. The bright annealed finish we use reduces friction during forming operations – something spring makers appreciate when coiling hundreds of identical pieces.

Dimensional control is where we focus our process:

– Standard diameters from 0.2mm to 10mm with ±0.02mm tolerance

– Available in ASTM A580, JIS G4309, and GB/T 4240 specifications

– Three surface options: bright (for high visibility), matte (for reduced glare), or polished (for food-grade applications)

We often get asked about magnetism. In its annealed state, 304 is typically non-magnetic, but cold working can induce slight magnetic properties – something to consider if you’re building sensitive electronic components.

Why Fabricators Keep Coming Back

One thing we’ve learned? The best materials disappear into the background. You don’t want to be fighting your wire when you’re making precision fasteners or delicate jewelry findings. That’s why we maintain strict control over surface finish and ovality – because nobody has time for wire that jams in their forming machines.

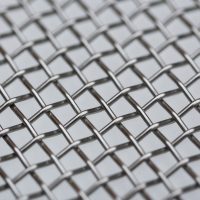

As a Chinese manufacturer, we combine direct mill pricing with the flexibility to handle custom specs. Need 500kg of 1.2mm wire with a specific hardness range for your filter mesh? Or 2000m of 0.3mm wire with special packaging for automated feeding? We’ve done it. Our facility runs 24/7, so we can handle rush orders without the typical offshore delays.

We’re not just selling wire – we’re providing solutions that work in your actual production environment. Reach out with your challenges. We’ll tell you what we know, even if it’s that another grade might work better. That’s how lasting supplier relationships start.