Description

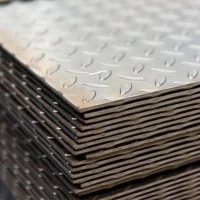

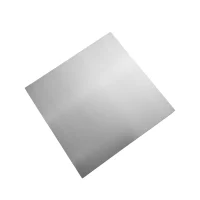

316L Marine Grade Stainless Steel Plate

Crafted for exceptional corrosion resistance and durability in harsh marine and industrial environments, our 316L stainless steel plate is the ideal solution for demanding applications. Engineered to meet stringent ASTM A240/ASME SA240 standards, this low-carbon variant of 316 stainless steel delivers superior performance with enhanced weldability and formability.

Key Features

- Marine-Grade Corrosion Resistance: Contains 2-3% molybdenum to resist pitting, chloride-induced corrosion, and saltwater degradation.

- Low Carbon Content (≤0.03%): Minimizes carbide precipitation during welding, ensuring optimal strength and corrosion resistance in welded structures.

- High-Temperature Stability: Maintains integrity in temperatures ranging from -196°C to 800°C (-321°F to 1472°F).

- Non-Magnetic Properties: Retains non-magnetic characteristics post-processing, ideal for sensitive electronic applications.

- Aesthetic Finish: Smooth, polished surfaces (2B, BA, or custom finishes) for both functional and decorative uses.

- Eco-Friendly & Recyclable: 100% recyclable, aligning with sustainable manufacturing practices.

Specifications

- Material Grade: 316L (UNS S31603, EN 1.4404)

- Thickness: 0.3mm – 100mm (customizable)

- Width: 1000mm – 2000mm (standard); up to 3000mm (custom)

- Length: 2000mm – 6000mm (standard); cut-to-order available

- Standards: ASTM A240, ASME SA240, EN 10088-2, JIS G4304

- Surface Treatments: 2B, No.4, HL, BA, Mirror, Embossed, Etched (custom options)

Applications

- Shipbuilding & marine hardware (propellers, valves, pumps)

- Chemical processing equipment (tanks, pipelines, reactors)

- Food & beverage processing machinery

- Architectural cladding and structural components

- Medical devices and pharmaceutical equipment

Customization & Quality Assurance

We are a China-based steel manufacturing factory specializing in custom 316L stainless steel plates tailored to your exact specifications. Whether you require unique dimensions, specialized surface finishes, or additional processing (e.g., laser cutting, bending), our ISO 9001-certified facility ensures precision and consistency. Contact us for competitive pricing, bulk orders, or technical support—we provide a full suite of stainless steel solutions.

Have specific requirements? Contact us today to discuss your project needs.