Description

The Wire That Knows Its Job

We’ve been making baling wire for over fifteen years, and one thing we’ve learned? The best wire isn’t always the strongest—it’s the one that works where you need it. Our Black Annealed Baling Wire was developed after watching recycling crews struggle with brittle wires that snapped during compaction, or agricultural workers waste time straightening kinked bundles. This is why we focus on the balance between ductility and strength—something many overlook.

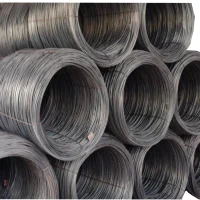

Unlike standard high-carbon wires that prioritize stiffness, we use low-carbon steel (0.06–0.12% C) and anneal it in controlled-atmosphere furnaces. The result? A wire with 500–700 MPa tensile strength, yet capable of ≥15% elongation—meaning it bends before it breaks. That 0.8mm to 4.0mm diameter range? We’ve had customers use 1.2mm wire for compacted PET bottles and 3.5mm for scrap metal bales. The black oxide finish isn’t just for looks; it reduces friction by ~30% compared to bright wire, making it safer to handle and easier to feed through automatic balers.

Real Performance Where It Counts

- In recycling plants, this wire maintains integrity through multiple compaction cycles. One of our clients in Germany reduced wire breakage by 40% after switching from standard annealed wire.

- Farmers appreciate how the light oil coating prevents rust during short-term outdoor storage (up to 3 months, depending on humidity). No one wants to deal with brittle, rusty hay bales come winter.

- For construction use, the soft-annealed structure makes it ideal for temporary bundling of rebar or mesh panels—it’s easy to tie by hand without gloves, yet holds up to 200kg load in a standard knot.

We pack coils (25–500kg, inner diameter 150–500mm) with waterproof paper and woven fabric, or palletize for container shipping. Every batch meets ASTM A764 and EN 10264, and we can tweak specs—whether it’s a tighter diameter tolerance (±0.02mm) or a heavier oil film.

Built for Your Needs, Not Ours

As a Chinese manufacturer with full control over our production, we don’t push pre-made solutions. Need cut-to-length wires for automated systems? We’ve done that. Want custom coil weights for ergonomic handling? No problem. Our MOQs start low, and lead times are tight because we’re not reselling someone else’s stock.

This wire is 100% recyclable, but honestly, the real sustainability story is in its durability—you use less over time. If you’re tired of wires that compromise on flexibility or longevity, reach out. We’ll send samples, talk specs, and get your order right—not because we have to, but because that’s how we’ve built our reputation.