Description

Carbon Steel Structural Plates: The Backbone of Modern Infrastructure

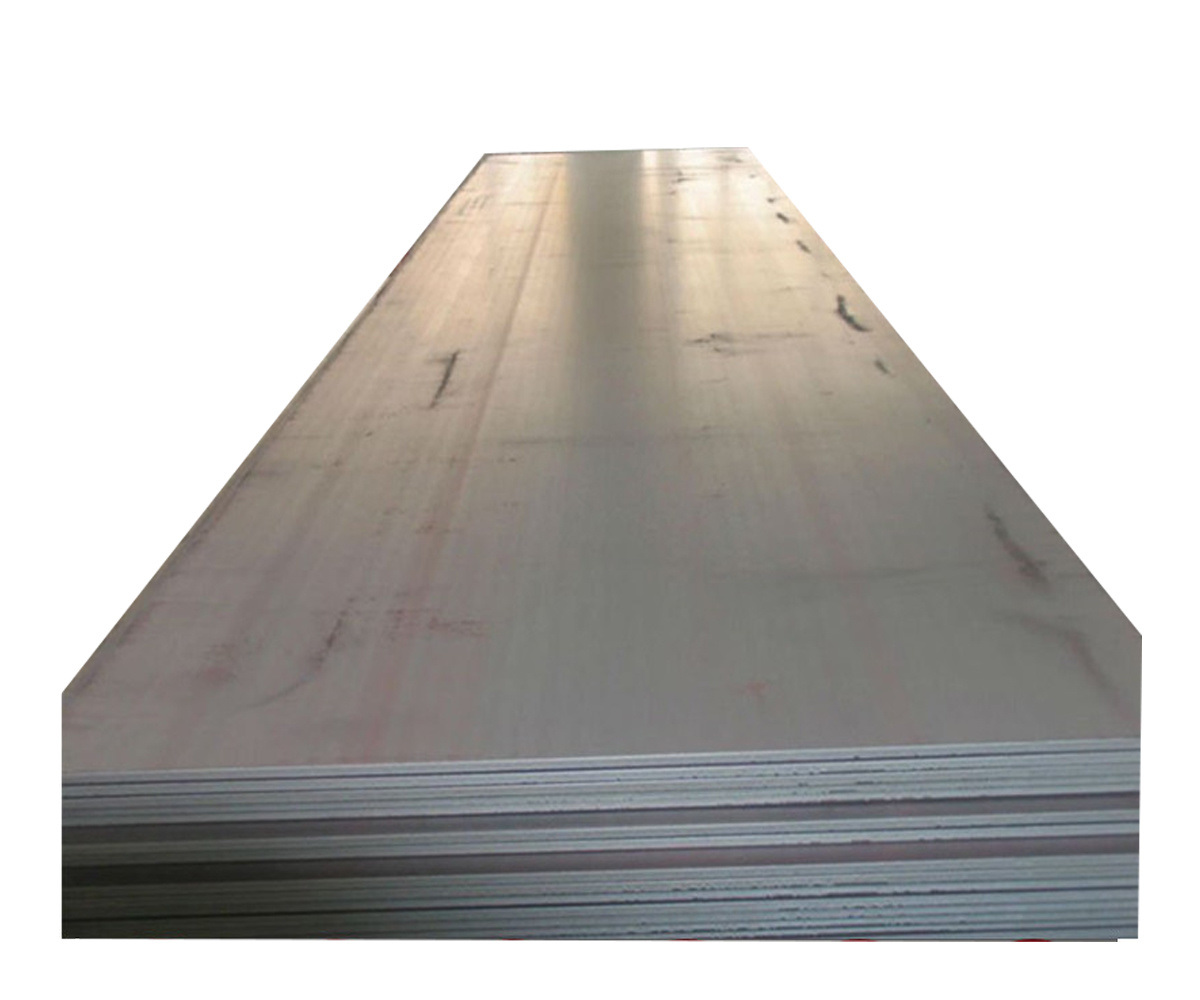

Carbon Steel Structural Plates are indispensable materials in the construction and engineering sectors, serving as the fundamental building blocks for a vast array of structures globally. Renowned for their exceptional balance of strength, ductility, and cost-effectiveness, these plates provide the critical support and resilience required for contemporary architectural marvels, robust industrial facilities, and vital infrastructure projects. Manufactured with precision, they are engineered to meet the stringent demands of various load-bearing applications.

Material Composition & Common Grades

Carbon steel structural plates are primarily composed of iron and carbon, with controlled additions of other alloying elements such as manganese, silicon, sulfur, and phosphorus. These elements fine-tune the steel’s mechanical properties, including strength, weldability, and toughness. The specific proportion of carbon dictates the steel’s hardness and strength, while other elements contribute to its overall performance.

Commonly specified grades for structural applications include:

- ASTM Standards (North America): A36 (general structural), A572 Grade 50 (high-strength low-alloy), A992 (structural steel for building frames).

- EN Standards (Europe): S235, S275, S355 (indicating minimum yield strength in MPa), often with specific impact testing requirements (e.g., JR, JO, J2, K2).

- JIS Standards (Japan): SS400, SM400, SM490 (general structural and welded structure applications).

- GB Standards (China): Q235B, Q345B, Q345C (general structural and high-strength structural steels).

Key Characteristics & Benefits

- High Strength-to-Weight Ratio: Provides excellent load-bearing capabilities without excessive bulk.

- Exceptional Weldability: Easily fabricated using standard welding techniques (SMAW, SAW, GMAW), allowing for complex structural assemblies.

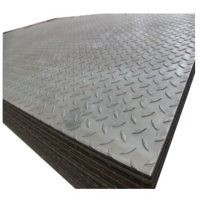

- Good Formability & Machinability: Can be cut, bent, drilled, and shaped into various components, offering design flexibility.

- Impact Toughness: Many grades exhibit excellent resistance to brittle fracture, especially at lower temperatures, crucial for safety and durability.

- Versatility: Suitable for a wide range of applications from simple frameworks to complex, high-stress structures.

- Cost-Effectiveness: Carbon steel is generally more economical than alloy steels, making it a preferred choice for large-scale projects.

- Durability: Engineered to withstand significant static and dynamic loads, ensuring long-term structural integrity.

Typical Specifications & Dimensions

Baoli Iron Steel offers carbon steel structural plates in a comprehensive range of dimensions to meet diverse project requirements. While custom dimensions are available upon request, our standard offerings typically include:

- Thickness: Ranging from 6mm to 200mm (or more, depending on grade and specific requirements).

- Width: Commonly from 1,500mm to 4,000mm.

- Length: Standard lengths from 6,000mm to 18,000mm, with the ability for custom cutting to precise specifications.

- Surface Finish: Typically supplied as mill finish, with options for shot blasting, priming, or other protective coatings to enhance corrosion resistance.

Applications Across Industries

The robust nature and versatility of carbon steel structural plates make them essential in countless applications, including:

- Building Construction: High-rise buildings, stadiums, shopping centers, warehouses, and factories.

- Bridge Construction: Components for road bridges, railway bridges, and pedestrian bridges.

- Infrastructure Projects: Dams, port facilities, offshore platforms, and wind turbine towers.

- Heavy Machinery: Frames and components for excavators, cranes, agricultural equipment, and mining machinery.

- Shipbuilding: Hulls, decks, and structural elements for various types of vessels.

- Industrial Equipment: Pressure vessels (for certain grades), storage tanks, and various fabricated industrial components.

Quality Assurance & International Standards

At Baoli Iron Steel, our commitment to quality is paramount. All carbon steel structural plates undergo rigorous testing and inspection processes to ensure they not only meet but exceed industry standards and customer expectations. We adhere strictly to international specifications such as ASTM, EN, JIS, and GB. Our quality control includes:

- Comprehensive chemical analysis

- Mechanical property testing (tensile strength, yield strength, elongation, impact toughness)

- Ultrasonic testing for internal defects

- Precise dimensional checks

- Certification to relevant standards (e.g., Mill Test Certificates – MTCs)

Why Choose Baoli Iron Steel?

As a leading Chinese manufacturer and exporter, Baoli Iron Steel is your trusted partner for high-quality carbon steel structural plates.

- Global Export Experience to numerous countries and regions

- Wide Range of Specifications and Custom Sizes Available

- Rigorous Quality Control and Compliance with International Standards

- Reliable Supply Chain and On-time Delivery

- Dedicated Customer Service and Technical Support