Description

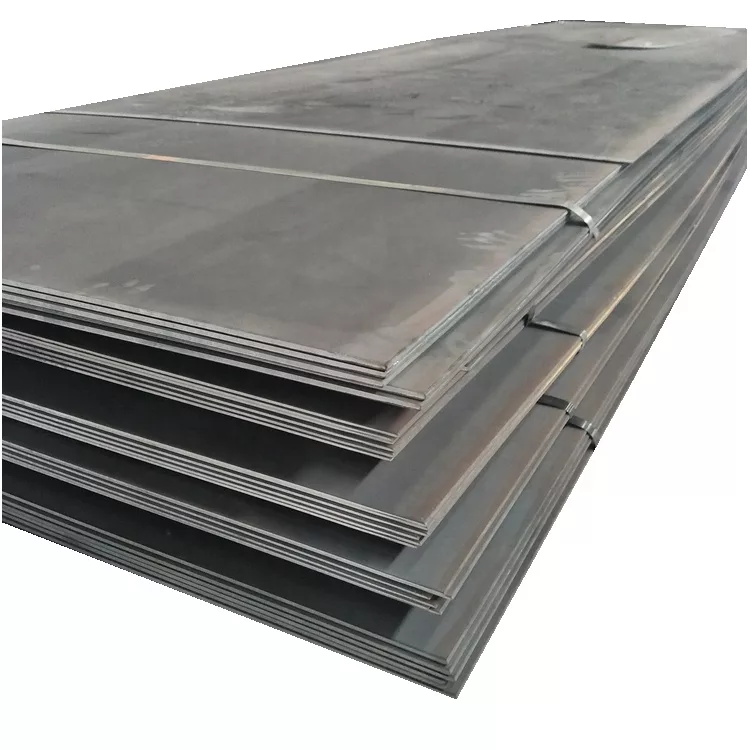

Cold Rolled Carbon Steel Plates – Precision & Performance by Baoli Iron Steel

At Baoli Iron Steel, we specialize in providing premium Cold Rolled Carbon Steel Plates, a testament to precision engineering and superior material science. These plates represent a significant advancement in steel processing, offering enhanced surface finish, superior dimensional tolerances, and improved mechanical properties compared to their hot rolled counterparts. They are the preferred choice for applications demanding both aesthetic excellence and robust performance.

Manufacturing Process: Achieving Excellence

The production of our cold rolled steel involves a meticulous, multi-stage process beginning with hot rolled pickled coil. This material undergoes further reduction at room temperature, passing through a series of rollers. This cold reduction process significantly reduces the thickness, refines the grain structure, and induces strain hardening, thereby enhancing the steel’s mechanical properties. Subsequent annealing (if required for ductility and formability) and temper rolling ensure optimal flatness, a bright, smooth surface finish, and precise mechanical attributes, making the steel ready for even the most demanding applications.

Key Features & Advantages:

- Unparalleled Surface Quality: Our cold rolled plates are renowned for their remarkably smooth, bright, and scale-free surface. This makes them ideal for demanding aesthetic applications and provides an excellent base for various coatings, painting, and plating, ensuring superior adhesion and a flawless finish.

- Exceptional Dimensional Accuracy: The cold rolling process allows for significantly tighter thickness tolerances and superior flatness compared to hot rolled products. This precision is crucial for automated manufacturing processes, complex stamping, and intricate fabrication.

- Enhanced Mechanical Properties: Through strain hardening, cold rolled plates exhibit substantially higher yield strength, tensile strength, and hardness. Depending on the grade and post-treatment (like annealing), they can also offer excellent formability and ductility, making them suitable for complex deep drawing and intricate forming operations without fracturing.

- Consistent & Uniform Properties: The controlled cold rolling environment ensures highly consistent mechanical properties throughout the entire plate, leading to predictable performance in manufacturing and end-use.

Technical Specifications:

Common Grades Available:

We supply a comprehensive range of cold rolled carbon steel grades tailored to specific application requirements, including but not limited to:

- Commercial Quality (CQ) / Drawing Quality (DQ) / Deep Drawing Quality (DDQ): Ideal for forming and drawing applications. Examples include:

- JIS G3141: SPCC, SPCD, SPCE, SPCG

- EN 10130: DC01, DC03, DC04, DC05, DC06, DC07

- ASTM A1008/A1008M: CS Type A/B, DS Type A/B, DDS, EDDS

- GB/T 700: Q195, Q215, Q235, 08AL

- Structural Grades: For applications requiring higher strength and rigidity.

- High Strength Low Alloy (HSLA) Grades: Available for specific projects demanding superior strength-to-weight ratios.

Available Dimensions & Standards:

- Thickness: Typically ranging from 0.3mm to 3.0mm, with custom gauges available upon request to meet precise project specifications.

- Width: Common widths from 600mm to 1500mm, or customized upon request.

- Length: Supplied in precision-wound coils, slit coils, or cut-to-length sheets according to customer specifications.

- Standards: Our products are compliant with major international standards including but not limited to ASTM A1008/A1008M, EN 10130, JIS G3141, GB/T 700, and more, ensuring global applicability and quality assurance.

Diverse Applications:

Due to their superior finish, precise dimensions, and enhanced mechanical properties, Baoli’s cold rolled carbon steel plates are widely utilized across numerous industries for both structural and aesthetic components:

- Automotive Industry: Body panels, internal components, structural parts, wheel discs.

- Appliance Manufacturing: Refrigerators, washing machines, ovens, microwave ovens, air conditioners.

- Furniture & Office Equipment: Desks, cabinets, shelving units, filing systems.

- Electrical Components: Casings, enclosures, conduit, lighting fixtures.

- Construction: Doors, frames, partitions, non-structural elements, ceiling grids.

- General Fabrication: Stamping, pressing, and bending applications requiring high precision and excellent surface finish.

- Pipes & Tubes: Formed and welded from cold rolled strip for various uses.

Why Choose Baoli Iron Steel?

- Global Reach: As a leading Chinese manufacturer, Baoli Iron Steel proudly exports our high-quality cold rolled carbon steel plates to numerous countries and regions worldwide, ensuring reliable delivery and exceptional service.

- Customization Expertise: We understand diverse project requirements. Our team is equipped to provide tailored solutions regarding specific dimensions, grades, and finishes to meet your exact needs.

- Unwavering Quality Assurance: Committed to stringent quality control, every plate from Baoli Iron Steel undergoes rigorous inspection to meet the highest industry standards, guaranteeing performance and durability.