Description

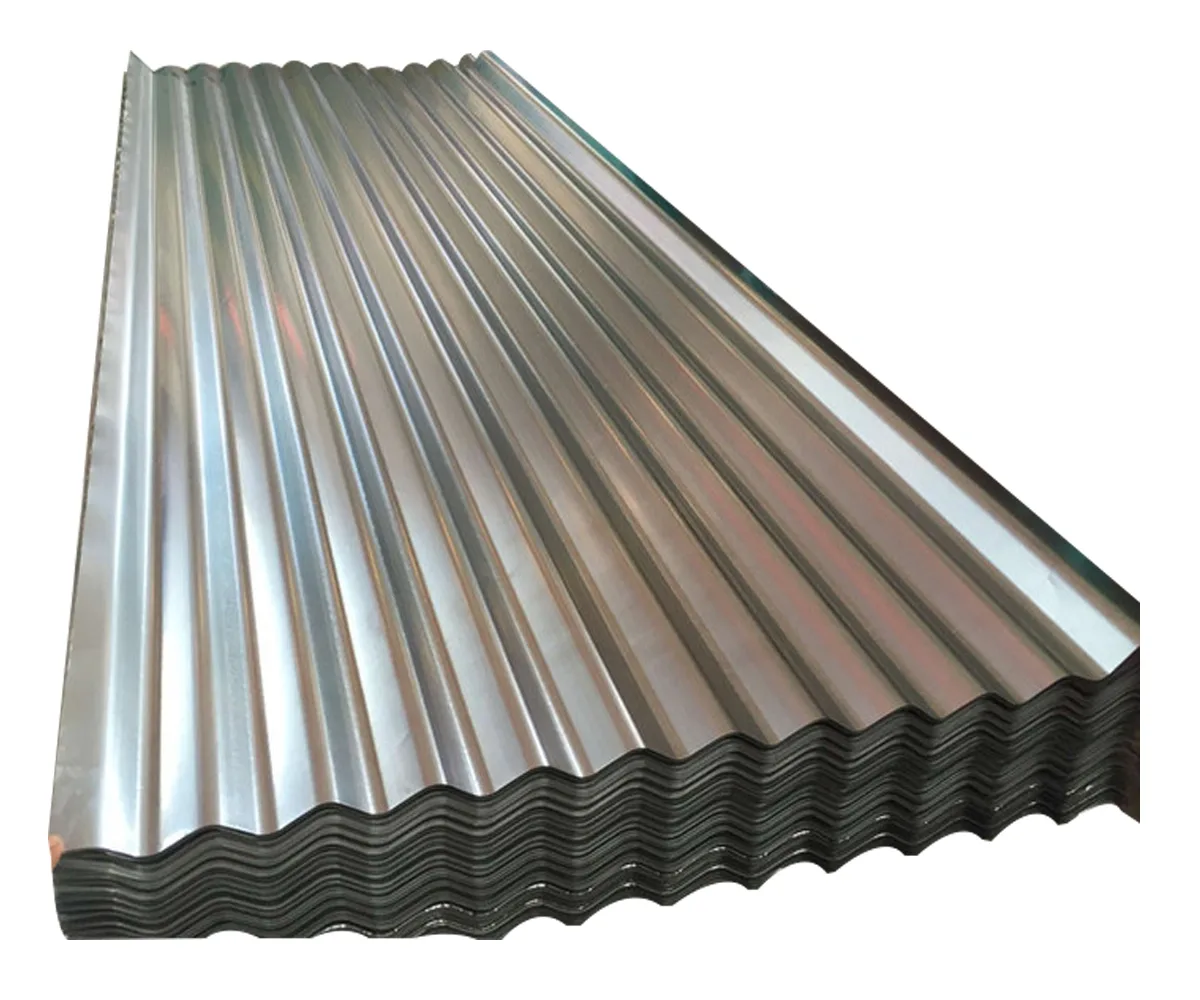

Discover Baoli Iron Steel’s Premium Galvanized Steel Roofing Sheets

Engineered for superior performance and longevity, Baoli Iron Steel’s galvanized steel roofing sheets represent the pinnacle of modern roofing solutions. Crafted from high-grade steel and fortified with a robust zinc coating, these sheets offer unparalleled protection against the elements, ensuring a durable, aesthetically pleasing, and cost-effective roofing solution for any residential, commercial, or agricultural project.

Key Features

-

Material Composition:

- Precisely manufactured from premium cold-rolled or hot-rolled steel coil, conforming to international standards such as ASTM A653, JIS G3302, and EN 10346 (common grades include SGCC, DX51D+Z).

- The steel base undergoes a meticulous hot-dip galvanizing process, applying a uniform zinc coating ranging from Z40 (40g/m2) to Z275 (275g/m2) on both sides, ensuring optimal corrosion protection tailored to diverse environmental conditions.

-

Superior Corrosion Resistance:

- The zinc coating provides dual-action protection: it acts as a physical barrier separating the steel from moisture and oxygen, and offers cathodic (sacrificial) protection, where the zinc corrodes preferentially to the steel even if the surface is scratched.

- This ensures exceptional resistance to rust, oxidation, and various atmospheric pollutants, significantly extending the roof’s lifespan in harsh industrial or coastal environments.

-

Unmatched Durability:

- Highly resistant to impact from hail, heavy snow loads, and strong winds.

- Inherently non-combustible, offering excellent fire resistance.

- Maintains structural integrity and aesthetic appeal over decades, often with a service life exceeding 20-50 years.

-

Lightweight Advantage:

- Significantly lighter than traditional roofing materials like clay tiles or concrete, reducing the structural load on buildings and simplifying foundation requirements.

- Facilitates easier handling, faster installation, and reduced transportation costs.

-

Versatility in Design:

- Available in a wide array of profiles, including corrugated (sine wave), trapezoidal (ribbed), and standing seam designs, catering to various architectural aesthetics and functional requirements.

- Options for factory pre-painted finishes in a full spectrum of RAL colors, or natural galvanized finish for an industrial look.

-

Ease of Installation:

- Designed for quick and efficient installation, reducing labor costs and project timelines.

- Can be easily cut, shaped, and secured using standard tools and self-tapping screws, offering flexibility for complex roof geometries.

Specifications

-

Nominal Thickness:

- Commonly available from 0.4mm to 1.2mm, with custom thicknesses upon request, optimized for specific load requirements and spans.

-

Width:

- Typically offered in widths ranging from 600mm to 1250mm (total width), with various effective covering widths depending on the chosen profile.

-

Length:

- Customizable lengths available, commonly from 2 meters to 12 meters, allowing for seamless roofing sections and minimized wastage.

-

Zinc Coating Mass:

- Available from Z40 (40 g/m2) to Z275 (275 g/m2), selected based on the desired level of corrosion resistance and projected service life.

-

Finish Options:

- Standard Hot-Dip Galvanized (Natural Zinc Finish).

- Pre-painted Galvanized Iron (PPGI) with various top coats (e.g., Polyester, PVDF) and back coats, available in a vast range of RAL colors.

-

Applicable Standards:

- ASTM A653/A653M, JIS G3302, EN 10346, GB/T 2518.

Applications

- Residential Roofing: Ideal for houses, garages, carports, and sheds, providing a modern aesthetic with long-lasting protection.

- Commercial & Industrial Buildings: Widely adopted for warehouses, factories, retail spaces, and workshops due to their durability, low maintenance, and quick installation.

- Agricultural Structures: Perfectly suited for barns, greenhouses, livestock housing, and storage facilities where moisture resistance and robust performance are critical.

Advantages

- Cost-Effective: Lower initial material cost combined with minimal maintenance requirements offers significant long-term savings and a strong return on investment.

- Eco-Friendly: Steel is 100% recyclable, making galvanized steel roofing an environmentally responsible and sustainable building material.

- Energy Efficiency: Can be specified with light-colored or reflective coatings to reduce heat absorption, contributing to lower cooling costs and improved building energy performance.

- Low Maintenance: Requires only periodic cleaning and inspection, minimizing upkeep efforts over its long service life.

Maintenance Guidelines

- Routine Cleaning: Regular cleaning with water and mild detergents is recommended to remove dirt, debris, and atmospheric deposits. Avoid abrasive cleaners or harsh chemicals.

- Periodic Inspection: Conduct annual inspections for any accumulated debris, leaf litter, or minor surface scratches. Promptly address any damage to the zinc coating with compatible touch-up paints to ensure continued protection.

- Drainage Checks: Ensure gutters and downspouts are clear to prevent water pooling on the roof surface.

Why Choose Baoli Iron Steel?

As a leading Chinese manufacturer and exporter of steel materials, Baoli Iron Steel is committed to delivering excellence. We offer:

- Global Export Capabilities: Serving a diverse range of countries and regions worldwide with reliable logistics.

- Comprehensive Product Range: Providing a wide array of specifications, dimensions, steel grades, and coating options to meet unique project requirements.

- Uncompromising Quality: Strict adherence to international quality standards (ISO 9001, CE) ensures superior product performance and reliability.

- Customized Solutions: Our experienced team can assist in tailoring products to your specific needs, ensuring optimal fit and function for your project.