Description

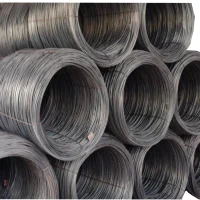

High Carbon Steel Wires: Unrivaled Strength and Precision from Baoli Iron Steel

At Baoli Iron Steel, we specialize in manufacturing High Carbon Steel Wires, meticulously engineered to deliver exceptional performance in the most demanding applications. With a carbon content typically ranging from 0.60% to over 1.00%, our wires are renowned for their superior hardness, impressive tensile strength, excellent wear resistance, and remarkable fatigue life.

Key Characteristics & Material Composition

- Precise Carbon Control: Our High Carbon Steel Wires are available in various grades, including but not limited to AISI 1060, 1070, 1080, 1090, and specific spring wire grades like SWC (Japanese Standards) / SWP (Japanese Standards), ensuring the optimal balance of strength and ductility.

- Enhanced Alloying Elements: Beyond carbon, the controlled addition of elements such as Manganese (for improved hardenability and strength), Silicon (for deoxidation and enhanced elasticity), and trace elements contributes to the wire’s overall superior mechanical properties and consistent performance.

- Optimized Microstructure: Through advanced drawing and heat treatment processes, our wires achieve a fine pearlitic structure, critical for maximum strength and resilience.

Superior Mechanical Properties & Manufacturing Excellence

Our manufacturing process involves state-of-the-art cold drawing and precise heat treatment techniques, including processes like patented drawing, quenching, and tempering. These processes are crucial for achieving the following mechanical properties:

- High Tensile Strength: Ranging from 1000 MPa (145 ksi) up to 2800 MPa (400 ksi) or higher, depending on the specific grade and diameter, ensuring the wire can withstand extreme loads without failure.

- Exceptional Hardness: Capable of achieving hardness levels suitable for wear-intensive applications, often up to 60 HRC after appropriate heat treatment.

- Excellent Fatigue Resistance: Vital for applications involving cyclic loading, such as springs, ensuring longevity and reliability.

- Good Wear Resistance: Ideal for components exposed to friction and abrasion.

Versatile Applications

The outstanding properties of Baoli Iron Steel’s High Carbon Steel Wires make them indispensable across a wide array of industries:

- Springs: Compression springs, extension springs, torsion springs, valve springs, clutch springs, and piano wire.

- Automotive Components: Seat frames, brake cables, control cables, clutch cables, and various suspension parts.

- Wire Ropes & Cables: High-strength cables for lifting, rigging, and structural applications.

- Brushes: Industrial brushes, cleaning brushes.

- Fasteners: High-strength bolts, screws, and washers (though often for specialty fasteners).

- Agricultural Machinery: Components requiring high strength and durability.

- Cutting Tools: Certain types of blades and tools (depending on specific alloy composition).

- General Machinery: Various components requiring high strength and wear resistance.

Available Specifications & Surface Finish

We offer a comprehensive range of specifications to meet diverse project requirements:

- Diameter Range: Typically from 0.15mm to 12.0mm (0.006 inches to 0.47 inches), with custom sizes available upon request.

- Surface Finish: Available in Bright, Galvanized, Phosphated, Brass Coated, or Oil Tempered finishes to suit specific application needs and improve corrosion resistance or adhesion.

- Packaging: Supplied in various forms including coils, spools, and cut-to-length bars, optimized for your production line.

- Standards: Conforming to international standards such as ASTM, DIN, JIS, EN, as well as specific customer specifications.

Why Choose Baoli Iron Steel? Your Trusted Partner

- Expertise & Customization: As a leading Chinese manufacturer, Baoli Iron Steel boasts extensive expertise in steel production. We provide tailored solutions in terms of material grade, precise dimensions, and specific surface treatments to meet your unique project demands.

- Global Reach: Our High Carbon Steel Wires are exported to numerous countries and regions worldwide, serving a diverse international clientele. We understand global logistics and ensure efficient, reliable delivery.

- Quality Assurance: We adhere to stringent quality control protocols at every stage of production, from raw material sourcing to final inspection, guaranteeing the highest quality and consistency for every batch.

- Comprehensive Support: From technical consultation on material selection to seamless order processing and reliable logistics, our team is dedicated to providing exceptional customer service.