Seaside Resort Construction: How to Prevent Steel Corrosion from Salt Air Exposure

Understanding the Threat: Why Salt Air Accelerates Steel Corrosion

Salt air presents one of the most aggressive environments for structural steel, particularly in seaside resort construction. The primary driver of corrosion in coastal zones is the presence of chloride ions—abundant in sea spray and airborne salt particles. When these chlorides combine with moisture and oxygen, they initiate and accelerate electrochemical reactions that degrade steel at an alarming rate. Unlike inland environments, coastal areas experience high humidity, frequent wind-driven salt spray, and significant temperature fluctuations—all of which create ideal conditions for corrosion cycles to thrive. Over time, this leads to pitting, rust formation, and ultimately, compromised structural integrity. For resorts—where safety, aesthetics, and longevity are paramount—uncontrolled corrosion can result in costly repairs, operational disruptions, and even liability risks.

Identifying High-Risk Areas in Seaside Resort Design

Not all steel components face equal exposure. Structural elements such as beams, columns, railings, and fasteners are especially vulnerable due to their direct contact with environmental stressors. Architectural features like cantilevered balconies, deep overhangs, and enclosed mechanical spaces often trap moisture and salt residues, creating microenvironments where corrosion accelerates unnoticed. Historical failures in coastal developments—such as spalling concrete due to rebar corrosion or collapsed railings from hidden section loss—highlight the importance of proactive risk assessment. Identifying these failure points during the design phase allows engineers to implement targeted protection strategies before construction begins.

Material Selection: Choosing Corrosion-Resistant Steel Alloys

The foundation of corrosion resistance starts with material choice. Stainless steel grades such as 316L, which contains molybdenum, offer superior performance in marine environments compared to 304, which lacks this critical alloying element. While 316L comes at a higher initial cost, its extended service life often justifies the investment through reduced maintenance and replacement needs. Weathering steels, like ASTM A588, form a protective rust layer in stable, dry conditions—but near saltwater, this patina breaks down, making them unsuitable for direct marine exposure. A thorough cost-benefit analysis should weigh upfront material expenses against lifecycle costs, factoring in inspection frequency, repair downtime, and potential revenue loss from guest-facing structural issues.

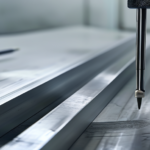

Protective Coatings and Surface Treatments

Even the most resilient alloys benefit from supplemental protection. Hot-dip galvanizing—immersing steel in molten zinc—creates a metallurgically bonded barrier that resists abrasion and provides cathodic protection to exposed areas. For enhanced durability, multi-layer coating systems combining epoxy primers with polyurethane topcoats offer excellent UV resistance and chemical shielding. In extreme environments, thermal-sprayed metal coatings using aluminum or zinc-aluminum alloys deliver long-term defense by forming a dense, impermeable layer. Each system requires specific surface preparation (typically to SSPC-SP 10/NACE No. 2 standards) and has defined reapplication cycles—ranging from 15 to 30 years depending on exposure severity and coating quality.

Cathodic Protection Systems for Long-Term Defense

For critical or submerged steel elements, cathodic protection (CP) adds an active layer of defense. Sacrificial anode systems use more electrochemically active metals—like magnesium or zinc—to corrode in place of the structural steel, ideal for pilings, seawalls, and underground supports. In large-scale resort developments, impressed current cathodic protection (ICCP) systems provide adjustable, long-lasting coverage by applying a controlled electrical current to counteract corrosion reactions. These systems must be carefully integrated with structural design and include remote monitoring capabilities to ensure consistent performance and timely maintenance alerts.

Design Strategies to Minimize Salt Exposure

Smart architectural detailing can significantly reduce corrosion risk. Designing sloped surfaces, drip edges, and open joints promotes rapid drainage and minimizes water retention. Overhangs should extend sufficiently to shield vulnerable connections from direct sea spray, while adequate ventilation in enclosed spaces prevents condensation buildup. Whenever possible, locate structural steel away from high-exposure zones—such as within building cores rather than on exterior façades. Landscaping also plays a role: planting salt-tolerant vegetation buffers and installing windbreaks can reduce airborne salt deposition on building surfaces by up to 40%, according to coastal engineering studies.

Construction Best Practices for Coastal Environments

Execution quality directly impacts corrosion resistance. Pre-construction site preparation must include thorough cleaning of substrates, controlled drying to prevent flash rust, and environmental monitoring during coating application. Steel components should be stored off the ground, covered, and protected from salt-laden winds. During fabrication, welding and bolting must avoid damaging existing protective layers, and all field-applied coatings should match factory specifications. Rigorous quality assurance—aligned with ASTM D610 for rust grading and ISO 12944 for coating durability—ensures compliance and long-term performance. Documentation of every treatment step creates a traceable record for future inspections and warranty claims.

Maintenance and Monitoring: Ensuring Lifelong Performance

A proactive maintenance regimen is essential for sustaining protection. Inspection schedules should be tailored to coastal conditions—typically biannual visual checks supplemented by ultrasonic thickness testing and electrochemical sensors for hidden corrosion. Salt residue should be gently removed using low-pressure freshwater rinsing; abrasive methods can compromise coatings. Facility managers should develop a formal corrosion management plan that outlines inspection protocols, response thresholds, and budget allocations. Integrating this plan into overall resort operations ensures continuity and accountability across ownership transitions or management changes.

Case Studies: Lessons from Successful Seaside Resort Projects

High-performing resorts in Florida, the Mediterranean, and Southeast Asia demonstrate the ROI of strategic corrosion control. One luxury resort in the Maldives used 316L stainless steel for all exterior railings and fasteners, combined with thermal-sprayed aluminum coatings on primary structural members—resulting in zero corrosion-related repairs after 12 years. Another project in Miami Beach implemented an ICCP system for its marina supports, reducing annual maintenance costs by 60% compared to neighboring properties relying solely on coatings. These cases underscore that upfront investment in robust materials and systems pays dividends in operational reliability and guest satisfaction.

Regulatory and Sustainability Considerations

Compliance with local building codes—such as Florida’s High-Velocity Hurricane Zone standards or EU Marine Equipment Directives—is non-negotiable. International standards like ISO 12944 and NORSOK M-501 provide frameworks for selecting appropriate protection systems based on environmental categories. Sustainability also matters: low-VOC coatings minimize air pollution, recyclable stainless steels support circular economy goals, and energy-efficient CP systems reduce carbon footprints. Proper disposal of spent anodes and coating waste must follow hazardous material regulations to prevent ecological harm.

Future-Proofing Your Resort Against Evolving Coastal Challenges

As sea levels rise and storm intensity increases, resorts must adopt forward-looking strategies. Emerging technologies like self-healing microcapsule coatings—which release corrosion inhibitors upon damage—and AI-driven sensor networks enable predictive maintenance before failures occur. Integrating resilience into early design phases, rather than retrofitting later, ensures adaptability to changing conditions. By combining proven methods with innovation, developers can build seaside resorts that withstand not only today’s challenges but tomorrow’s uncertainties—delivering safety, beauty, and value for decades to come.