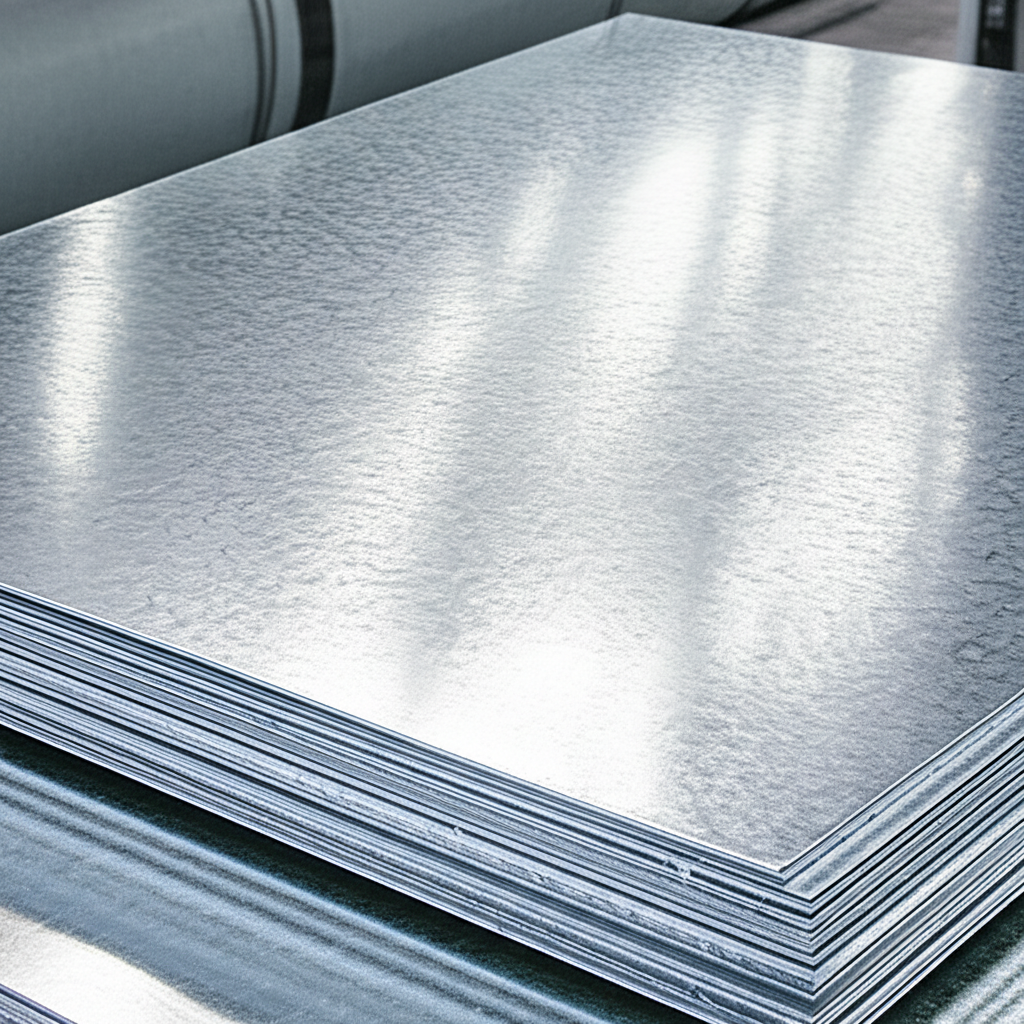

The automotive industry is undergoing a transformative shift toward lightweighting, driven by stringent emissions regulations, fuel efficiency demands, and the rise of electric vehicles (EVs). Among the materials enabling this transition, galvanized steel has emerged as a critical solution, combining high strength, corrosion resistance, and cost-effectiveness. This article explores the strategic sourcing of galvanized steel for automotive lightweighting, covering key considerations, technical specifications, and real-world applications.

Why Galvanized Steel for Lightweighting?

Galvanized steel—carbon steel coated with a zinc layer—offers a unique balance of properties for automotive applications:

– Strength-to-weight ratio: Advanced high-strength steels (AHSS) with galvanized coatings achieve yield strengths of 500–1,200 MPa, enabling thinner gauges without compromising structural integrity.

– Corrosion resistance: The zinc coating (typically 60–275 g/m²) protects against oxidation, extending vehicle lifespan, especially in harsh environments.

– Formability: Galvanized steel retains excellent ductility, allowing complex shapes for body-in-white (BIW) components, chassis, and EV battery enclosures.

– Cost-efficiency: Compared to aluminum or composites, galvanized steel remains 20–40% more cost-effective for mass production.

Key Sourcing Considerations

When selecting galvanized steel for automotive lightweighting, manufacturers must evaluate the following parameters:

-

Coating Type and Thickness

- Hot-dip galvanizing (HDG): Standard for most automotive parts, offering a zinc-iron alloy layer for superior adhesion.

- Electrogalvanizing (EG): Provides a smoother surface, ideal for exposed panels requiring high-quality paint finishes.

- Zinc-magnesium coatings: Emerging solutions with enhanced corrosion resistance for underbody components.

-

Steel Grades and Standards

- AHSS grades: DP (Dual-Phase), TRIP (Transformation-Induced Plasticity), and CP (Complex Phase) steels are preferred for crash-resistant structures.

- Global standards: ISO 16120 (wrought steel), ASTM A1067 (HDG), and EN 10346 (continuous hot-dip coatings) ensure compliance.

-

Supply Chain Reliability

- Consistency: Batch-to-batch uniformity in mechanical properties and coating thickness is critical for stamping and welding.

- Lead times: Localized sourcing reduces logistics costs and carbon footprint—a key factor for EV supply chains.

-

Sustainability

- Recyclability: Steel is infinitely recyclable, with galvanized variants maintaining 95% recyclability rates.

- Eco-coatings: Low-spangle or zinc-nickel coatings reduce environmental impact during production.

Applications in Automotive Lightweighting

- Body Structures: A-pillars, B-pillars, and roof rails made from DP780 or DP980 reduce weight by 15–20% versus conventional steels.

- Chassis Components: Subframes and suspension arms benefit from TRIP590 for fatigue resistance.

- EV Battery Enclosures: Galvannealed steel (zinc-iron alloy coating) provides EMI shielding and crash protection.

- Exterior Panels: EG-coated HSLA steels ensure dent resistance and aesthetic appeal.

Challenges and Mitigation Strategies

- Hydrogen Embrittlement: High-strength steels are prone to hydrogen absorption during galvanizing. Post-coating baking (200°C for 2–4 hours) mitigates this risk.

- Welding Complexity: Zinc coatings can cause weld spatter. Laser welding or adhesive bonding offers alternatives.

- Cost Fluctuations: Locking in long-term contracts with suppliers stabilizes pricing amid volatile raw material markets.

Future Trends

- Ultra-thin coatings: Nano-zinc coatings promise further weight reduction without sacrificing corrosion resistance.

- Hybrid material designs: Combining galvanized steel with aluminum or composites for multi-material lightweighting.

Partnering with a Trusted Supplier

For automotive manufacturers seeking tailored solutions, baoli, a leading Chinese steel manufacturer, offers custom galvanized steel products designed for lightweighting. With expertise in AHSS grades, eco-coatings, and just-in-time delivery, baoli supports global OEMs in achieving their sustainability and efficiency goals. From material selection to supply chain optimization, their team provides end-to-end solutions for next-generation vehicles.

In conclusion, sourcing galvanized steel for automotive lightweighting requires a strategic approach—balancing performance, cost, and sustainability

Sourcing Galvanized Steel for Automotive Lightweighting — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.