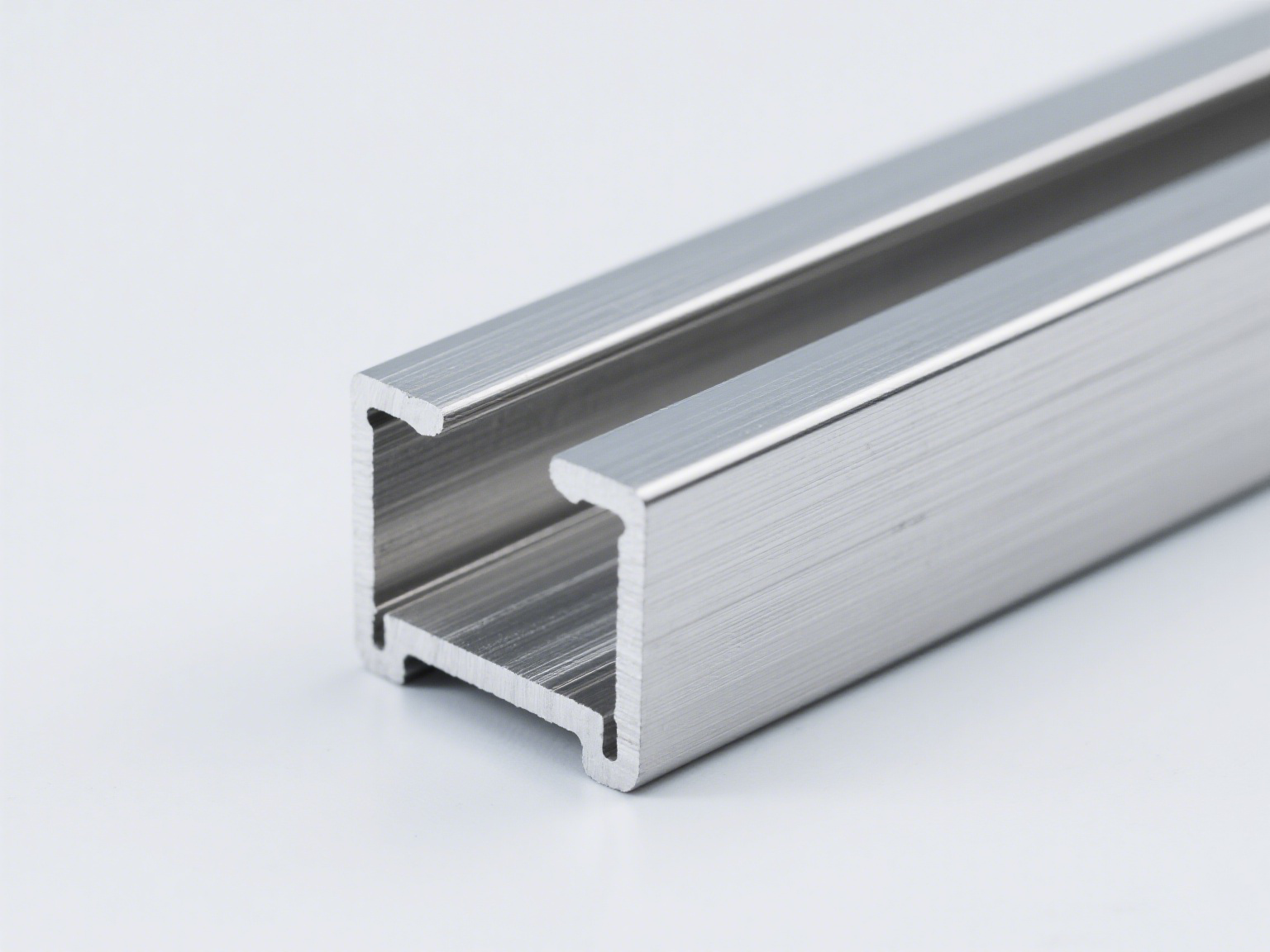

In modern industrial construction and structural engineering, the selection of framing materials plays a critical role in determining durability, safety, and long-term performance. Among the available options, stainless steel channel bar has emerged as a top-tier choice for industrial framing due to its exceptional mechanical properties, resistance to environmental degradation, and versatility in design. At BaoLi Iron & Steel Co., Ltd, we specialize in manufacturing premium-grade stainless steel channel bars tailored to meet the rigorous demands of industrial applications across sectors such as manufacturing, transportation, and heavy infrastructure.

One of the most compelling advantages of stainless steel channel bars is their outstanding resistance to corrosion. Unlike carbon steel or galvanized steel components that require protective coatings and regular maintenance, stainless steel contains a minimum of 10.5% chromium, which forms a passive oxide layer on the surface. This layer self-repairs in the presence of oxygen and prevents rust, pitting, and chemical attack—crucial for industrial environments exposed to moisture, chemicals, or fluctuating temperatures.

In addition to corrosion resistance, stainless steel channel bars offer high tensile strength and excellent load-bearing capacity. These properties make them ideal for structural support in framing systems where dimensional stability and safety are non-negotiable. Whether used in equipment platforms, conveyor supports, or building substructures, our stainless steel channel bars ensure maximum structural integrity under demanding mechanical stress.

Technical Specifications of Stainless Steel Channel Bars

To assist engineers and procurement teams in selecting the right product, we provide detailed technical data for our most commonly used stainless steel grades in channel bar production. Below is a comparative table highlighting key mechanical and chemical properties.

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|

| 304 / 304L | 515 min | 205 min | 40 min | Food processing, chemical tanks, indoor framing |

| 316 / 316L | 530 min | 215 min | 40 min | Marine environments, pharmaceutical, offshore platforms |

| 430 | 450 min | 205 min | 22 min | Architectural trim, indoor structural support |

As the table shows, grades such as 316L offer enhanced resistance to chloride-induced corrosion, making them ideal for coastal or high-humidity environments. BaoLi Iron & Steel ensures all our stainless steel channel bars are produced in accordance with international standards including ASTM A276, JIS G4303, and GB/T 1220, guaranteeing consistency and reliability in every batch.

Customization and Application Flexibility

Industrial projects often require non-standard dimensions or specialized finishes. BaoLi Iron & Steel excels in offering customized cutting, bending, and surface treatment options for stainless steel channel bars. From 2-meter cut lengths to full container-load orders with laser marking, our production line supports flexible configurations to match your engineering drawings and site requirements.

Furthermore, our dedicated technical support team assists clients in selecting the optimal grade and section size based on load analysis, environmental exposure, and installation methods. This client-centric approach ensures not only product suitability but also long-term operational efficiency.

With a global logistics network and strict quality control protocols—from raw material sourcing to final inspection—BaoLi Iron & Steel delivers premium stainless steel solutions on time and within specification. Choose reliability. Choose performance. Choose BaoLi Iron & Steel for your next industrial framing project.

Stainless Steel Channel Bar: Key Features That Make It a Top Choice for Industrial Framing — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.