Introduction to Stainless Steel Chequered Plates

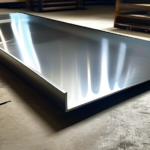

Stainless steel chequered plates—also known as tread plates, diamond plates, or anti-slip plates—are engineered metal sheets featuring raised patterns designed to enhance grip and reduce slip hazards in industrial, architectural, and transportation applications. Unlike their aluminum or carbon steel counterparts, stainless steel chequered plates offer superior corrosion resistance, durability, and aesthetic appeal, making them ideal for harsh environments such as marine, chemical processing, and food handling facilities.

These plates are manufactured through a cold-rolling process that imparts a raised pattern (typically diamond-shaped) onto the surface, increasing structural rigidity and slip resistance. The integration of stainless steel as the base material ensures long-term performance even under extreme conditions. For a deeper understanding of stainless steel’s metallurgical properties, refer to the Stainless steel Wikipedia page.

Key Grades of Stainless Steel Used in Chequered Plates

The performance of a chequered plate is heavily influenced by the grade of stainless steel used. Each grade offers a unique balance of mechanical strength, corrosion resistance, and cost-effectiveness.

Austenitic Stainless Steel (300 Series)

The most widely used grades in chequered plate manufacturing are from the 300 series, particularly AISI 304 and AISI 316.

- AISI 304 (1.4301): This grade contains 18% chromium and 8% nickel, offering excellent formability and moderate corrosion resistance. It is ideal for indoor applications, architectural cladding, and light industrial flooring. Its non-magnetic nature (in annealed condition) and ease of fabrication make it a go-to choice for general-purpose chequered plates.

- AISI 316 (1.4401): With the addition of 2–3% molybdenum, 316 significantly outperforms 304 in chloride-rich environments (e.g., coastal areas, marine applications). It is the preferred grade for offshore platforms, chemical tanks, and food processing equipment. For more on molybdenum’s role in corrosion resistance, see Molybdenum.

Ferritic and Duplex Stainless Steels (400 Series & 2205)

- AISI 430 (1.4016): A cost-effective ferritic grade with 16–18% chromium but no nickel. While less ductile and more prone to stress corrosion cracking, it is suitable for indoor, non-critical applications where cost is a primary concern.

- Duplex 2205 (1.4462): Combining austenitic and ferritic microstructures, this grade offers high strength (nearly double that of 304) and excellent pitting resistance. It is increasingly used in heavy-duty industrial flooring and structural components where both strength and corrosion resistance are critical.

Specialty Grades and Custom Alloys

In niche applications, super austenitic (e.g., 904L) or precipitation-hardening grades may be used for extreme environments. However, these are typically reserved for high-budget projects due to cost and limited availability.

Common Patterns and Surface Profiles

The pattern on a chequered plate is not merely aesthetic—it directly affects slip resistance, load distribution, and cleanability.

Diamond (Tread) Pattern – The Industry Standard

The most common pattern, featuring interlocking diamond shapes with raised edges, provides multidirectional grip. Standard heights range from 0.8 mm to 2.0 mm, with larger profiles offering better traction but reduced flatness.

- Applications: Stair treads, walkways, vehicle flooring, and industrial platforms.

- Advantages: High slip resistance, easy to clean, widely available.

Lentil (Round) and Linear Patterns

- Lentil Pattern: Features raised circular or oval shapes. Offers moderate slip resistance and a smoother surface, suitable for architectural applications where aesthetics are prioritized.

- Linear (Ribbed) Pattern: Longitudinal ridges provide directional grip. Often used in conveyor systems and ramps where movement is primarily linear.

Custom and Hybrid Patterns

Some manufacturers offer custom embossing, including logos, directional arrows, or hybrid designs combining diamond and linear elements. These are used in branding, safety signage, and specialized machinery.

Note: Pattern depth and spacing must comply with regional safety standards (e.g., OSHA, EN 13374) to ensure adequate slip resistance.

Load Ratings and Structural Performance

Understanding load-bearing capacity is critical when selecting chequered plates for structural or flooring applications. Load ratings depend on material grade, plate thickness, pattern geometry, and support spacing.

Factors Influencing Load Capacity

- Thickness: Standard thicknesses range from 2.0 mm to 6.0 mm. Thicker plates (≥4 mm) are used in heavy industrial settings (e.g., forklift traffic, crane platforms).

- Support Spacing: The distance between supporting beams or joists directly affects deflection. Closer spacing increases load capacity.

- Pattern Height: Higher profiles increase rigidity but may reduce effective thickness under load. A 2.0 mm high diamond pattern on a 3.0 mm base plate reduces the load-bearing cross-section to 1.0 mm.

Load Rating Standards and Testing Methods

- Deflection Limits: Industry standards (e.g., AISC, Eurocode 3) typically limit deflection to L/360 (span divided by 360) under live loads.

- Uniform Load vs. Point Load: Chequered plates are tested under both conditions. For example, a 4 mm 304 stainless steel plate with 1.5 mm diamond pattern may support 1.5 kN/m² uniformly or 1.2 kN at a single point (depending on span).

- Fatigue Resistance: In cyclic loading environments (e.g., vehicle traffic), duplex grades like 2205 offer superior fatigue life due to higher yield strength.

Tip: Always consult manufacturer load tables or perform finite element analysis (FEA) for critical installations.

Real-World Load Examples

| Application | Recommended Grade | Thickness | Max Load (Uniform) |

|---|---|---|---|

| Pedestrian Walkway | 304 | 3.0 mm | 1.0 kN/m² |

| Forklift Platform | 316 | 4.5 mm | 3.5 kN/m² |

| Offshore Decking | 2205 | 5.0 mm | 5.0 kN/m² |

Selection Criteria: Matching Grade, Pattern, and Load Needs

Choosing the right chequered plate requires a systems approach that balances performance, environment, and cost.

Environmental Considerations

- Indoor/Non-Corrosive: 304 with standard diamond pattern.

- Coastal/Marine: 316 or 2205 with deeper pattern for drainage.

- Chemical Exposure: 316L (low carbon) or 904L for resistance to acids and chlorides.

Safety and Compliance

- Slip Resistance: Use R10–R13 rated plates (per DIN 51130) for high-risk areas.

- Fire Resistance: Stainless steel is non-combustible (Class A1), making it ideal for fire escape routes.

- Hygiene: Smooth, non-porous surfaces (e.g., polished 316) are required in food and pharmaceutical industries.

Cost vs. Longevity Trade-offs

While 304 is 20–30% cheaper than 316, the latter’s extended service life in corrosive environments often justifies the premium. Use life-cycle cost analysis (LCCA) to evaluate long-term value.

Maintenance and Longevity of Stainless Steel Chequered Plates

Proper maintenance ensures decades of service. Key practices include:

- Regular Cleaning: Use mild detergents and soft brushes to prevent chloride buildup.

- Passivation: Reapply passivation treatments after welding or surface damage to restore the chromium oxide layer—critical for corrosion resistance. Learn more about passivation at Passivation (chemistry).

- Inspection: Check for pitting, crevice corrosion, or pattern wear, especially in high-traffic zones.

With minimal upkeep, stainless steel chequered plates can last 30+ years, outperforming coated carbon steel alternatives.

Conclusion: Engineering Excellence in Anti-Slip Solutions

Stainless steel chequered plates represent a convergence of material science, structural engineering, and safety design. By selecting the appropriate grade, pattern, and thickness—and verifying load ratings—engineers and architects can deploy solutions that are not only functional but also sustainable and cost-effective over time.

From the corrosion-resistant 316 in marine environments to the high-strength 2205 in industrial flooring, the versatility of stainless steel ensures a tailored solution for every application. As standards evolve and new alloys emerge, the future of chequered plate technology remains firmly rooted in performance-driven innovation.