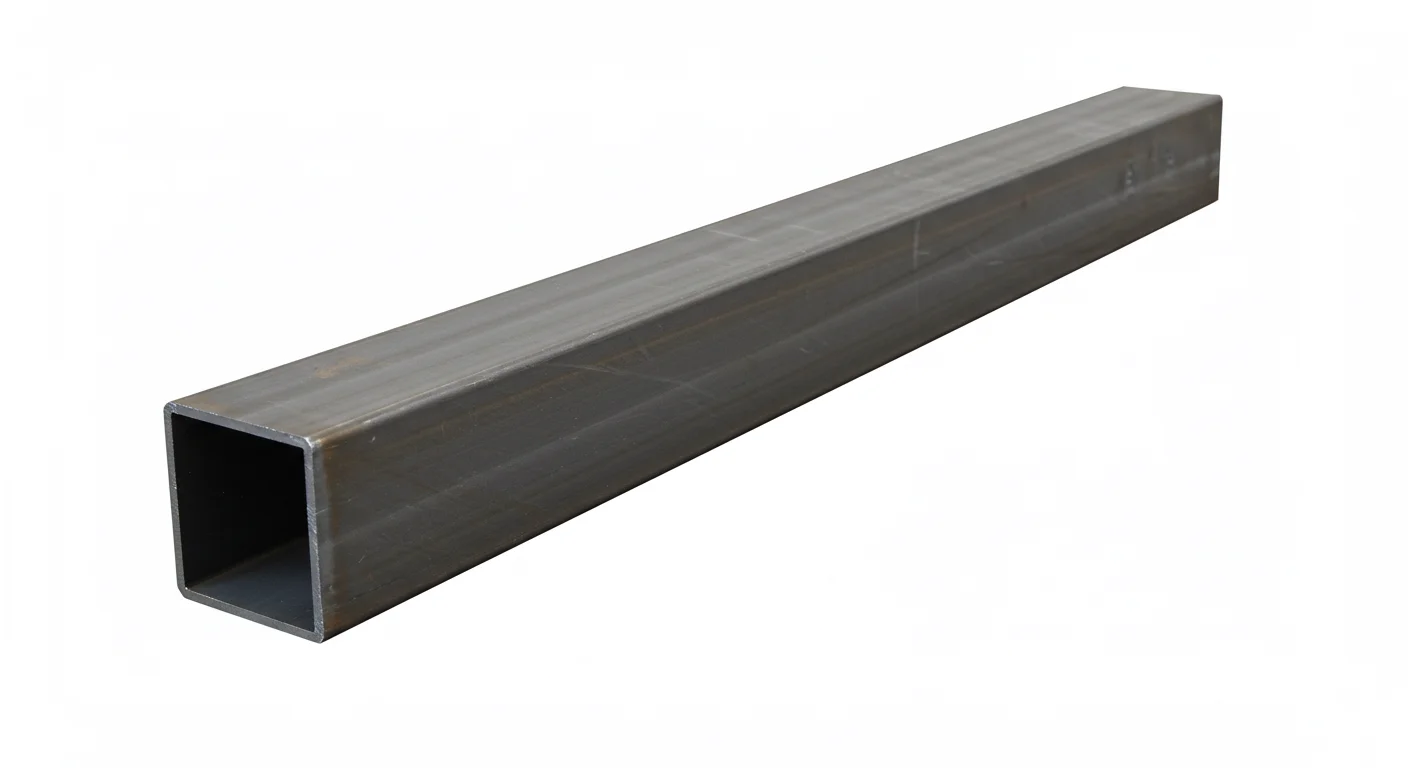

## The World of Stainless Steel Rectangular Tube Manufacturers: Quality, Variety, and Application

The phrase “stainless steel rectangular tube manufacturers” encompasses a vast and diverse industry, supplying a critical component to countless sectors globally. These manufacturers are responsible for producing high-quality, precisely engineered rectangular tubes made from stainless steel, a material prized for its durability, corrosion resistance, and aesthetic appeal. Understanding the landscape of these manufacturers reveals a complex interplay of factors influencing choice, ranging from material specifications to manufacturing processes and geographical location.

**Material Specifications:** The heart of the matter lies in the specific stainless steel grade used. Manufacturers offer tubes in various grades, each with different compositions and properties. Common grades include 304 (austenitic), 316 (austenitic with enhanced corrosion resistance), and 430 (ferritic), each suited to different applications. A critical aspect for buyers is understanding the precise chemical composition to ensure the tube meets the required performance standards for their specific project. This often involves consultation with manufacturers to determine the optimal grade for factors like environmental exposure, load-bearing capacity, and hygiene requirements.

**Manufacturing Processes:** The manufacturing process itself significantly impacts the quality and cost of the final product. Common techniques include cold drawing, hot rolling, and welding. Cold drawing produces tubes with tighter tolerances and superior surface finish, ideal for demanding applications. Hot rolling is more suitable for larger dimensions. Welded tubes are generally more cost-effective, but require careful consideration of weld integrity and potential weakening. Understanding these processes allows buyers to make informed decisions based on their budget and application requirements.

**Global Distribution and Market Dynamics:** Stainless steel rectangular tube manufacturers are scattered across the globe, with major production hubs in Asia, Europe, and North America. Each region boasts its own strengths, with some specializing in particular grades or manufacturing methods. This geographical distribution influences pricing, lead times, and logistics. Furthermore, the market is subject to fluctuations in raw material prices and global demand, impacting both availability and cost.

**Applications: A Broad Spectrum:** The versatility of stainless steel rectangular tubes makes them indispensable in various industries. They find extensive use in:

* **Construction:** Structural frameworks, handrails, architectural features.

* **Automotive:** Chassis components, exhaust systems, safety structures.

* **Food Processing:** Conveyor systems, processing equipment, hygienic enclosures.

* **Medical Equipment:** Surgical instruments, medical carts, laboratory equipment.

* **Furniture:** Modern designs, industrial styles, outdoor furniture.

**Choosing the Right Manufacturer:** Selecting the appropriate manufacturer requires careful consideration of several factors:

* **Reputation and experience:** A proven track record ensures quality and reliability.

* **Capacity and lead times:** Manufacturers with sufficient capacity meet production deadlines.

* **Quality control measures:** Robust quality control processes guarantee consistent product quality.

* **Certifications and compliance:** Compliance with relevant industry standards is crucial.

* **Pricing and payment terms:** Competitive pricing and favorable payment options are essential.

In conclusion, the realm of stainless steel rectangular tube manufacturers is complex and dynamic. Choosing the right partner requires a thorough understanding of material specifications, manufacturing processes, market dynamics, and the specific application requirements. Careful consideration of these factors ensures the selection of a high-quality product, delivered on time and within budget, contributing to the success of any project.

Stainless Steel Rectangular Tubes: Manufacturers, Grades, & Applications — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.

Leave a Reply