Automotive steel is a toolbox. You pick from mild steel, HSLA and advanced high‑strength steels (AHSS) to hit weight, crash and cost targets—and you match coatings and surface to your stamping and welding plan.

What goes where

- Mild steel (IF, low‑carbon): Easy stamping; inner panels, brackets.

- HSLA: Stronger with decent formability; rails, cross‑members.

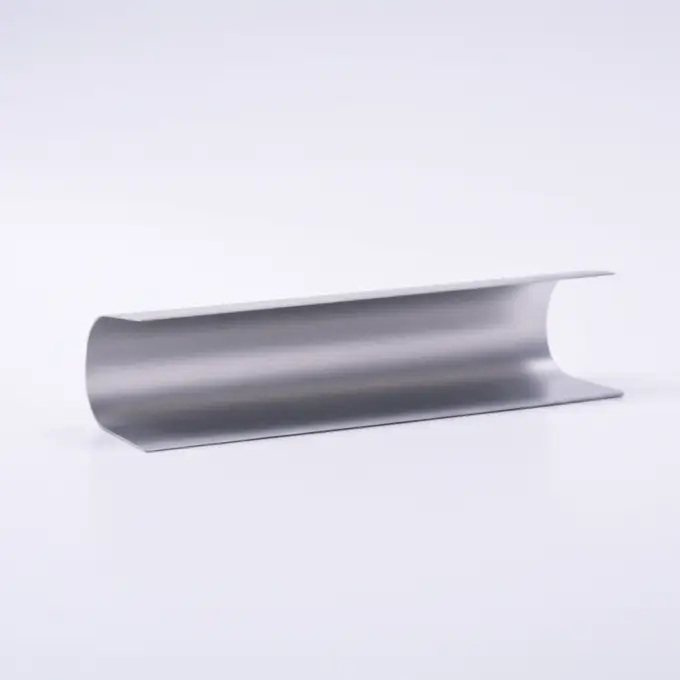

- AHSS (DP, TRIP, martensitic): High strength/energy absorption; crash structures and reinforcements.

Coatings and surfaces

- GI/GA (zinc/zinc‑iron): Weld‑through, corrosion protection; pick based on weld splash/appearance needs.

- Al‑Si hot‑stamped: For press‑hardening steel; coating protects during hot forming.

- Surface: Specify roughness for paint and friction; control lube for galling.

Stamping and joining

- Match r/t limits and springback allowances to grade; tighter die radii need better lube and blanks.

- Plan joining: spot weld windows for coated steels, MIG/laser for tailored blanks, or structural adhesives for mixed materials.

Spec snippet

- DP600, 1.2 mm, GI Z140; Ra 1.3–1.9 μm; r‑value target per panel class; weld window verified.

Share the panel, target mass and process route. We’ll propose a steel/coating pair and supply blanks or coils tuned to your dies.