- Material Types

Our comprehensive range includes:

- Carbon Steel Tubing

- Excellent strength-to-weight ratio

- Ideal for structural applications

- Cost-effective solution

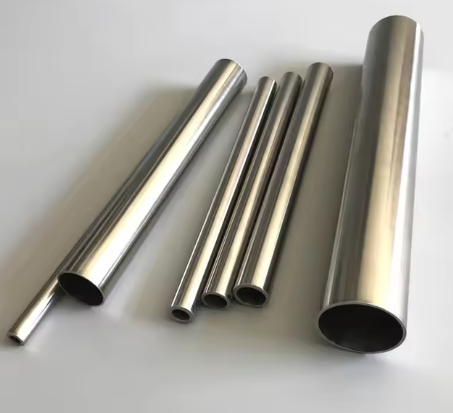

- Stainless Steel Tubing

- Superior corrosion resistance

- Perfect for food-grade applications

- Available in various grades (304, 316, etc.)

- Aluminum Tubing

- Lightweight and durable

- Excellent for aerospace applications

- Corrosion-resistant properties

- Copper Tubing

- Outstanding thermal conductivity

- Ideal for plumbing and HVAC

- Naturally antimicrobial

- Shape Varieties

We offer multiple profiles to suit your specific needs:

- Round tubes (most common)

- Square tubes

- Rectangular tubes

- Oval tubes

- Custom shapes available upon request

Quality Assurance and Standards

Every product in our inventory meets or exceeds industry standards:

- ASTM specifications

- ISO certifications

- EN standards

- Custom specifications available

- Full material traceability

- Quality testing documentation

Applications and Industries Served

Our metal tubing solutions cater to various sectors:

- Construction Industry

- Structural support

- Handrails and barriers

- Architectural elements

- Manufacturing

- Machine components

- Equipment fabrication

- Production line systems

- Automotive

- Exhaust systems

- Frame components

- Fluid transfer systems

- Energy Sector

- Oil and gas pipelines

- Power plant components

- Renewable energy systems

Wholesale Advantages and Value Proposition

Why choose us for your metal tubing needs:

- Competitive Pricing Structure

- Volume-based discounts

- Regular price promotions

- Bulk order savings

- Long-term contract benefits

- Inventory Management

- Large stock availability

- Just-in-time delivery options

- Warehouse storage solutions

- Stock monitoring services

- Technical Support

- Expert consultation

- Material selection assistance

- Engineering support

- Custom solution development

- Logistics and Delivery

- Nationwide shipping network

- International delivery options

- Express delivery available

- Custom packaging solutions

Custom Solutions and Specifications

We understand that standard products don’t always meet specific requirements. Our custom services include:

- Custom lengths and dimensions

- Special alloy formulations

- Surface treatment options

- Custom end finishing

- Specialized coating applications

- Heat treatment services

How to Get Started

- Initial Consultation

- Discuss your requirements

- Review technical specifications

- Explore material options

- Analyze application needs

- Quote Process

- Detailed pricing breakdown

- Volume discount options

- Delivery timeframes

- Payment terms

- Order Fulfillment

- Quality inspection

- Documentation preparation

- Shipping arrangements

- Delivery tracking

Value-Added Services

We go beyond just supplying metal tubing:

- Technical Documentation

- Material certificates

- Test reports

- Compliance documentation

- Installation guides

- After-Sales Support

- Technical assistance

- Problem resolution

- Maintenance advice

- Product training

Where to Find Quality Metal Tubing at Wholesale Prices — This article provides a practical buyer‑focused overview with specifications, selection tips, and on‑site considerations. Explore related topics: blog.

Key Specifications and Standards

- Standards: ASTM / EN / JIS (e.g., ASTM A240/A36, EN 10088/10025, JIS G4304/G3131).

- Surface options: 2B, BA, No.4, HL, mirror; galvanized (electro / hot‑dip).

- Processing: hot‑rolled, cold‑rolled, annealed & pickled, welded or seamless.

- Typical services: slitting, shearing, cut‑to‑length, drilling, beveling, deburring.

- Documentation: MTC, CO, packing list with net/gross weight and heat numbers.

Typical Applications

Construction, machinery, automotive, energy, enclosures and fencing, food equipment (for stainless), and general fabrication. Match grade and finish to corrosion, strength, and appearance requirements.

Selection Guide

- Use certified material with Mill Test Certificate (MTC).

- Confirm standards (ASTM/EN/JIS) and tolerances per drawing.

- Match surface finish to application (2B/BA/No.4/galvanized).

- Specify dimensions and acceptable deviation upfront.

- Plan packaging and corrosion protection for transit.

Processing, Packaging and Logistics

We adopt edge protection, waterproof wrapping, rust‑inhibiting paper, fumigated pallets, and strapping suitable for sea freight. Loading photos and weight lists are provided for each shipment.

FAQs

Q: What lead time can I expect?

A: Typically 7–15 days ex‑works for standard sizes; custom processing may extend the schedule.

Q: Can you provide cut‑to‑size service?

A: Yes. We slit, shear, cut, drill, bevel and deburr to drawing to reduce waste and speed installation.

Q: How do you ensure quality?

A: Incoming inspection, process control, and final inspection with traceable heat numbers; third‑party inspection is available.

Q: Do you support small trial orders?

A: We support pilot quantities with consolidated shipping to control cost.

All values are typical and for guidance only; confirm with the datasheet and purchase order before production.

Related products: view details.

Related products: view details.